PRODUCT FEATURES

Long Weld Neck Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

Long Weld Neck Flange: Everything You Need to Know

When it comes to selecting the right flange for your piping system, there is no question that a weld neck flange is the best option. But what exactly is a long weld neck flange and how do you know if it’s the right choice for your project?

The long weld neck flange is a long-necked pipe fitting that has been welded to the base of an opening. It is used in piping systems where there are no other openings available or where the existing openings are too small for standard long neck flange.

In this blog post, we will discuss how it is used, and some of its benefits. We will also provide you with some tips on purchasing a long weld neck flange, so you can get the best product for your needs. So, if you’re interested in learning more about weld neck flanges, keep reading!

Table of contents

1. Long Weld Neck Flange and Its Uses

The long weld neck flange (also known as LWN) is a long-necked pipe fitting that has been welded to the base of an opening. It is used in piping systems where there are no other openings available or where the existing openings are too small for standard long neck flanges.

Long weld neck flanges are available in a variety of lengths, with 9 inches, 12 inches, and 16 inches being the most popular. Because the lengths are determined by the pieces required for each application, there is no universal length for these industrial long neck flanges.

It can be used in any application where pipes need to go through walls, ceilings, or floors. It is often used as an access point for water, gas, and other types of pipes that require long necks to reach their destination without breaking off at the base of a long weld neck fitting.

The long weld neck flange can be installed on either side of a wall or floor joist so it does not take up much space. It can also be installed in areas where there is limited space, such as in a crawlspace or attic.

Uses of long weld neck flange:

- Long weld neck flanges are commonly used in the petroleum and chemical industries.

- They are also often used in power plants, refineries, and other manufacturing facilities.

- Some long weld neck flanges can even be used in the food industry.

2. How Is It Different From a Standard Weld Neck Flange

The long weld neck flange is very similar to the standard weld neck flange, but it has a longer neck. This makes it ideal for use in applications where there are no other openings available or where the existing openings are too small for standard long neck flanges.

Long neck flanges often known as nozzle, are pipes that can be replaced. The tip of a standard weld neck flange has a weld prep, but the end of a long weld neck flange has a square cut rather than a schedule bore.

Long weld neck flanges have a beveled flange that fits snugly against the pipe, adding strength. Weld neck flange connectors with a long weld neck improve pipe flow. Furthermore, piping systems that are reinforced with lengthy weld neck flanges are safer.

Compared to standard weld neck flange, this type of flange aids in balancing pressure and temperature fluctuations in the liquid running through the pipeline. This makes them better suited for high-pressure applications, as it helps to reduce the chances of leakage.

Additionally, long weld neck pipe flanges are less likely to experience stress corrosion cracking. This is because the long neck helps to distribute the load evenly across the flange.

3. Benefits of Using a Long Weld Neck Flange Over Other Types of Flanges

These benefits help people to know that a long weld neck flange is a great option. It is something that should be considered when making a decision on which flange to use. Here are the benefits of using a long weld neck flange.

| 1 | Increased Strength |

| 2 | Increased Flexibility |

| 3 | Easy to Install and Align |

| 4 | Extremely Strong and Reliable |

| 5 | Assures the Smooth Flow of the Liquid Passing Through Them |

Increased Strength

The long weld neck flange is more resistant to failure than standard weld neck flanges because of its long neck. This makes it ideal for high-pressure applications.

Increased Flexibility

The long weld neck flange can be installed in areas where there is limited space, such as in a crawlspace or attic. It can also be installed on either side of a wall or floor joist so it does not take up much space.

Easy to Install and Align

The long weld neck flange is very easy to install and align. It can be installed in minutes without the need for special tools or equipment.

Extremely Strong and Reliable

The long weld neck flange is extremely strong and reliable. It can handle high amounts of pressure without leaking or breaking.

Assures the Smooth Flow of the Liquid Passing Through Them

The long weld neck flange assures the smooth flow of the liquid passing through them. This is because they are less likely to experience turbulence and pressure loss. This design eliminates turbulence within the pipe, which is a typical cause of erosion, resulting in stronger, longer-lasting pressure vessel connections.

4. 3 Tips on Selecting the Right Size of Long Weld Neck Flange

Selecting the right size of long weld neck flange is very important because it will determine the strength and reliability of the connection. Failure to do so may cause problems in the future. Here are some guidelines to help you select the right size of long weld neck flange:

#1 Determine the Diameter of the Flange

The first thing you need to do is determine the diameter of the long weld neck flange. This can be done by measuring the inside diameter of the pipe.

The next step is to measure the outside diameter of the pipe. Once you have both measurements, you can then select the appropriate size of the long weld neck flange.

If you are unsure of the diameter, you can always ask a professional for help.

#2 Determine the Length of the Neck

The next thing you need to do is determine the length of the neck. This can be done by measuring the distance from the center of the pipe to the end of the weld neck. Once you have this measurement, you can then select the appropriate size of long weld neck flange.

#3 Determine the Thickness of the Flange

The next thing you need to do is determine the thickness of the long weld neck flange. This can be done by measuring the distance from the top of the flange to the bottom.

Once you have this measurement, you can then select the appropriate size of long weld neck flange. As long as you follow these guidelines, your long weld neck flange should work well for its intended purpose!

5. Installing a Long Weld Neck Flange

Installing a flange is a very crucial part of the process. This must be done properly to avoid any potential problems. Here is a step by step guide for installing weld neck flange:

Step #1 Clean the Surface Area

Clean the pipe and flanged fittings of any oils or debris. This will help ensure a leak-proof seal when the weld neck flange is installed.

Step #2 Threading

Thread the weld neck flange onto the end of the pipe. Make sure to use a pipe wrench to tighten the weld neck flange onto the pipe.

Step #3 Secure the Flange to the Pipe

If you are using a long weld neck flange, make sure that the pipe is long enough to accommodate the neck. The pipe should be at least two times longer than the neck.

Once you have determined that the pipe is long enough, use a pipe wrench to secure the flange to the pipe. Make sure that the flange is aligned with the pipe and tighten it to a torque of between 85 and 100-foot pounds.

Step #4 Welding

Place the weld neck flange near a welding machine and weld it to the end of the pipe. Make sure to weld the entire circumference of the weld neck flange to ensure a leak-proof seal.

Step #5 Check For Leaks

Test the long weld neck flange for leaks. Apply water or air pressure to the pipe and make sure there are no leaks. If there are any leaks, re-weld the weld neck flange until it is leak-proof.

Step #6 Install Gaskets and Bolts

Install the weld neck flange’s gasket and bolts. Make sure to use a torque wrench to tighten the bolts to the correct specifications.

6. Long Weld Neck Flange Standard

Different standards have been set for long weld neck flanges. This is to ensure that the flanges are made to a certain quality and specification. The most common standards for long weld neck flanges are:

ANSI/ASME B16.47

This is the American standard for long weld neck flanges. It covers flanges with a diameter of between 26 inches and 60 inches. ANSI stands for the American National Standards Institute and ASME stands for American Society of Mechanical Engineers.

MSS SP-44

This is the American standard for long weld neck flanges. It covers flanges with a diameter of between 24 inches and 60 inches. MSS stands for Manufacturers Standardization Society.

DIN EN 1561

This is the German standard for long weld neck flanges. It covers flanges with a diameter of between 26 inches and 60 inches. DIN stands for Deutsches Institut fur Normung which is the German Institute for Standardization.

BS 450

This is the British standard for long weld neck flanges. It covers flanges with a diameter of between 24 inches and 48 inches. BS stands for British Standard.

JIS B2220

This is the Japanese standard for long weld neck flanges. It covers flanges with a diameter of between 15 inches and 60 inches. JIS stands for Japanese Industrial Standard.

Other standards have been set for long weld neck flanges, but these are the most common ones. If you are unsure of which standard to use, consult with a professional. The long weld neck flange you select should be made to one of these standards to ensure that it meets your requirements.

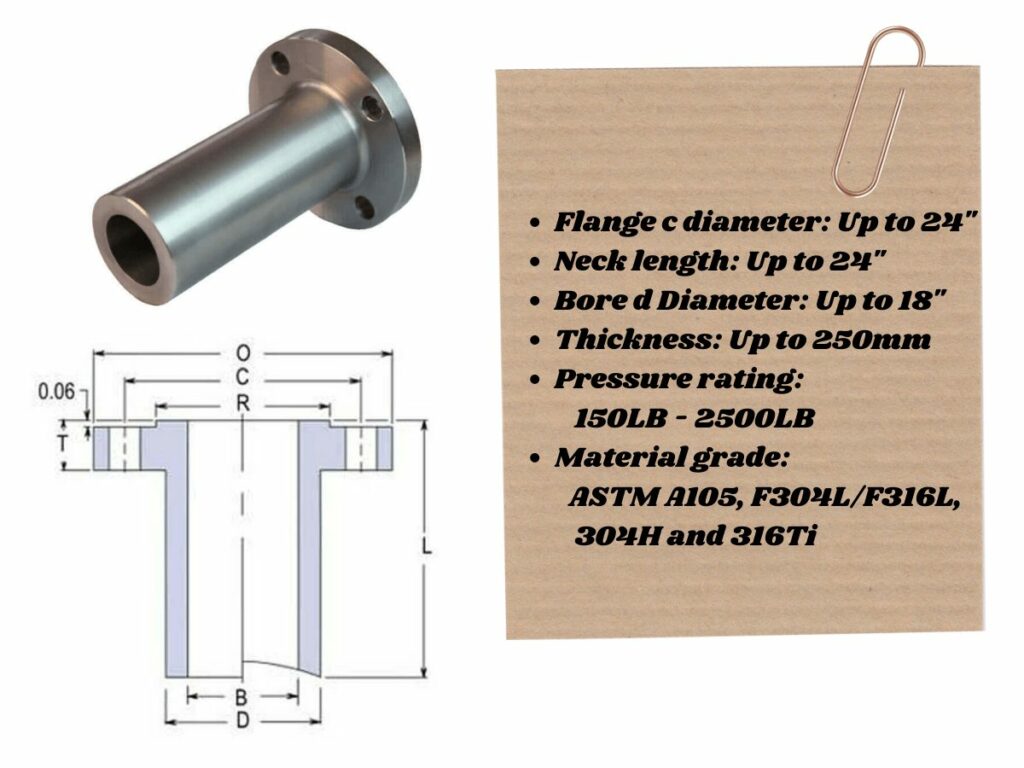

7. Dimensions of a Long Weld Neck Flange

A long weld neck flange has a longer neck than a standard weld neck flange. This allows for more material to be used in the welding process, which results in a stronger joint. Here are a raised face long weld neck flange dimensions 150:

- Flange c diameter: Up to 24″

- Neck length: Up to 24″

- Bore d Diameter: Up to 18″

- Thickness: Up to 250mm

- Pressure rating: 150LB – 2500LB

- Material grade: ASTM A105, F304L/F316L, 304H and 316Ti

Below is an image of the long weld neck nozzle thickness chart as well as the long weld neck flange dimensions class 150.

8. 5 Tips on Buying a Long Weld Neck Flange

There are several tips on buying a long weld neck flange. These are helpful to keep in mind when shopping for a long weld neck flange. Here are some tips on buying a long weld neck flange.

#1 Choose the Right Size

Make sure you choose the right size flange for your application. The flange diameter should be matched to the pipe diameter, and the neck length should be long enough to provide a strong joint.

#2 Consider the Material Grade

The material grade of the long weld neck flange should match the material of the pipe. American Society for Testing and Materials (ASTM) A105 is standard carbon steel, while F304L/F316L are stainless steels. 304H and 316Ti are higher-strength variants of 304L and 316L.

#3 Choose the Right Flange Type

There are many types of flanges, such as slip-on flanges, blind flanges, and weld neck flanges. Make sure to choose the right type of flange for your application.

#4 Buy From a Reputable Manufacturer

Make sure you buy your long welding neck flange from a reputable manufacturer such as Oflange. This will ensure that you get a quality product that meets all the required standards.

#5 Check For the Maximum Pressure Rating

The maximum pressure rating of the long weld neck flange should meet or exceed the operating pressure of your application. It is important to choose a long weld neck flange that is rated for the correct pressure.

A long neck flange is suitable for applications where long welding length, high strength, and good stress distribution are required. For high-pressure applications, a long weld neck flange is the best choice. Make sure you choose the right size, material grade, and flange type for your application.

9. Conclusion

If you are looking for a strong and reliable weld neck flange, then you should consider using a long weld neck flange.

This type of flange is manufactured by the forging or casting process, which makes it stronger and more reliable than other types of weld neck flanges. It’s also available in various grades, sizes, and specifications to meet your specific needs.

Contact us today at Oflange to learn more about our long weld neck flanges and how they can benefit your business.