PRODUCT FEATURES

Socket Weld Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

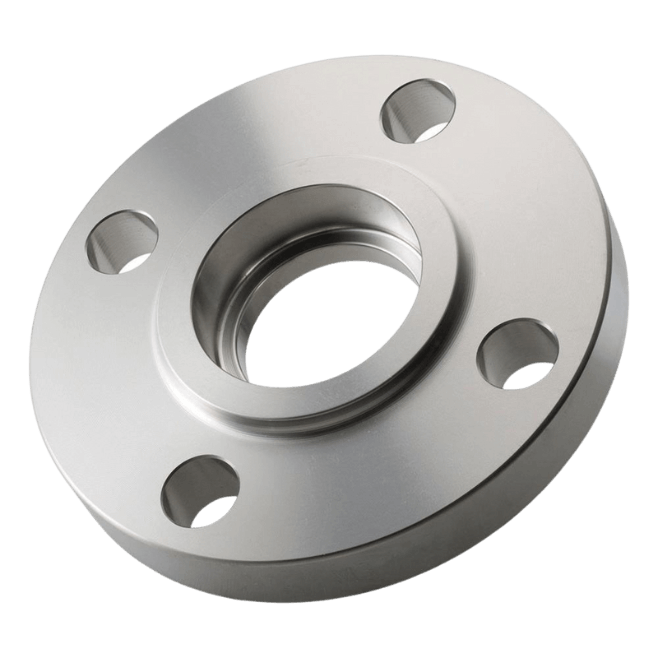

Socket Weld Flange

The socket weld flange is a type of flange that is used to connect pipe fittings. It has a socket that is welded to the pipe. The flange has a hole in the middle that is used to attach the flange to the pipe fitting.

Installing socket weld flanges is also simple. You just have to slide the socket of one fitting into the socket of another fitting, then clamp it together using a pair of wrenches.

There are many types of socket weld flanges, each with its form factor. The socket can be round or flat, and can also differ in size.

Table of contents

1. Socket Weld Flange Definition and How It Works

Socket weld flanges are fittings that are used to join two pipes together. They are usually made from stainless steel, brass, or copper. Socket weld flanges are similar to slip-on flanges, except that they have a socket on the inside of the flange that allows them to be welded to the pipe.

The socket weld pipe flange is inserted into the pipe and then welded in place. This type of flange is very strong and can withstand high pressure due to socket weld flange dimensions.

Socket weld flanges are typically used for high-pressure applications than fillet weld. They can be found in a variety of pipe sizes. Stainless steel socket weld flanges are among the most popular because they can withstand erosion and corrosion as well as chemicals that attack other metals.

2. Socket Weld Flange Key Features

Socket weld flanges are some of the most popular types of flanges in use today. They offer several key features that make them an ideal choice for many applications:

Easy To Install and Use

Socket weld flanges are the easiest type of flange to install and remove since they require no bolts or welding. They can be installed in minutes to bolt holes and easily removed for service.

Strong and Durable

Socket weld flanges are very strong. Their socket connection provides a reliable seal that resists pressure, even if the socket is worn or damaged.

Leak-Proof

Socket flange is the only flange type designed to be installed without bolts or welding. They are stronger than other socket-type flanges, thanks to their socket connection that provides a reliable seal even if the socket is worn or damaged.

Corrosion-Resistant

Socket weld flanges are made of stainless steel and other corrosion-resistant materials, so they do not rust or corrode.

Economical

Socket weld flanges are priced very affordably, so they are popular for use in the aerospace industry.

3. Parts & Construction of Socket Weld Flange

Socket weld flange fittings are those that have a socket weld connection. The socket weld flange is used to provide a means of connecting the piping system to the equipment. It is important to ensure that the socket weld flange fittings are of the same material as the pipe and the equipment.

The parts of the socket weld flange are:

Socket

This part of the socket weld flange is where the piping system is connected. It is either a socket or raised face socket weld flange.

Nut

This part is used to secure the socket weld flange fittings. It is either a hex socket or round socket depending on the socket weld flange.

Gasket

This is used to maintain the pressure within the socket weld flange fitting. It is important to ensure that the gasket is clean before you place it onto the socket weld flange.

O-Ring

This is used to provide a fluid-tight socket weld flange fit. It is used where there is fluid passing through the socket weld flange.

The construction of a socket weld flange is similar to that of a slip-on fitting, but it has the socket added. The socket tightens against the gasket on the other piece to help make it airtight.

4. The Difference Between a Socket Weld Flange and Other Types of Flange

When it comes to socket weld flanges, there are some major differences from other types of flange:

Used in Piping and Plumbing Systems

Socket weld flanges are a type of flange that is commonly used in piping and plumbing systems. They are a type of weld neck flange, which means that they have a protrusion on the neck of the pipe that allows them to be welded to the pipe. This makes them a very strong and durable type of flange.

Welded to the Piping

Another difference of socket weld flange from other types of flange is socket weld flanges are welded to the piping. That means the socket weld flange has a socket on one side that fits into another socket which makes welding possible.

Welded to the Equipment

Socket flange is the only socket type that is also weld socket flange, socket flange can be used in piping systems to connect hard materials or equipment. The socket weld flanges are connected by welding to metal surfaces.

If you want to know more about socket weld flange, please check out our website at Oflange. We have more information on socket weld flanges.

5. Socket Weld Flange Sizes

Socket weld flanges are available in several sizes. The most common sizes in inches and in millimeters are:

| Inches | Millimeters |

|---|---|

| 1/2″ | 15 mm |

| 3/4″ | 19 mm |

| 1″ | 25 mm |

| 1-1/4″ | 32 mm |

| 1-1/2″ | 40 mm |

| 2″ | 63 mm |

| 2-1/2″ | 75 mm |

| 3″ | 88 mm |

| 100 mm |

These socket weld flange sizes are also available in either grade 304 stainless steel or ASTM A105 cast steel. The socket size corresponds to the socket inside diameter, not outside diameter or thread size. (See the socket weld flange dimensions pdf)

6. Manufacturing Process of Socket Weld Flange

The manufacturing process of socket weld flange is not very different in comparison to other socket weld flanges in the market. The socket weld flange also undergoes almost the same process.

Step #1 Selection of Materials

The socket weld flange manufacturing process begins with the selection of materials. The materials must be strong and able to withstand high temperatures. They are then cut to size and shape.

Step #2 Create the Socket Weld Flange Hole

The next step is to create the socket weld flange hole. This is done by using a special machine that drills the hole into the center of the flange. The hole must be perfect to ensure a tight seal.

Step #3 Clean the Flanges

The next step is to clean the flanges. They are then heated and placed into a socket welding machine. The machine creates a very high heat that melts the metal and forms a seal. The socket weld flange is then cooled and inspected for defects.

Step #4 Packaging and Shipping

Finally, the socket weld flanges are inspected for defects before being tested. If they pass the test, they are packed and shipped to customers.

7. Benefits of Using Socket Weld Flange

Socket weld flange fittings are a great choice for connecting pipes because they provide a strong and leak-free connection. They are also easy to use, which makes them a popular choice for many applications. Some of the benefits of using socket weld flanges include:

Strong and Leak-Free Connection

Socket weld flange fittings are designed to create a strong and leak-free connection. They can be used with any piping material, including stainless steel, mild steel, and aluminum. This makes socket weld fittings a popular choice for many applications involving both new and existing pipes.

Easy and Convenient to Use

Socket weld flange fittings are easy and convenient to use. They can be connected by hand, so socket welds do not require torque wrenches or special tools. This reduces the time and labor involved with installing socket weld flanges.

Versatile Connection Options

Socket weld flange fittings provide a versatile connection option for pipes of many different shapes and sizes. They can be used with pipes that feature socket weld ends, and socket weld flange fittings are available in a variety of types.

Affordable and Easy to Maintain

Socket weld flange vs slip-on flange fittings is affordable and easy to maintain, which is a great advantage in areas where socket weld flanges tend to be used frequently. They can also be repaired quickly when needed because socket welds do not require welding or resurfacing.

8. Where to Find Wholesale Socket Weld Flange

If you’re in the market for socket weld flange, you’ll be happy to know that there are several places where you can find them. socket weld flange can be found at wholesale prices if you know where to look.

Online

The best place to start is online. Several websites sell socket weld flange, and most of them offer discounts for bulk orders.

Local Supplier

Another option is to check with your local supplier. They may not carry socket weld flanges in stock, but they may be able to order them for you.

Manufacturers

Finally, don’t forget about the manufacturers. Many of them produce socket weld flange, and they may be willing to sell them to you at a discounted price.

Oflange is a global manufacturer of pipe flanges and has been in business for several years. We provide innovative and high-quality products for use in applications such as pipeline systems, oil wells, gas processing plants, and refineries.

Our mission statement is to manufacture high-quality, durable, and affordable products that will serve the needs of their customers.

We offer a wide variety of products, including:

- Flange bolts and nuts

- Pipe flanges in various sizes and materials (steel or stainless steel)

- Steel piping systems for use in commercial and industrial facilities

- Stainless steel piping systems for use in commercial, residential, and industrial facilities.

9. Average Cost of Socket Weld Flange

When it comes to socket weld flanges, there are a few things you need to take into account. The most important thing is the size of the socket weld flange. You also need to consider the pressure rating of the socket weld flange. And finally, you need to think about the material that the socket weld flange is made out of.

The average cost of a socket weld flange is about $1.55 per flange. The size and pressure rating of the socket weld flange will affect the price, as will the material. So it’s important to consider all of these factors before you make your purchase.

If you want an exact price for socket weld flange, you can contact us at Oflange. Our socket welding specialists will be able to give you an exact quote, based on your specific needs.

10. 5 Tips for Socket Weld Flange Maintenance

Maintaining socket weld flanges is a process that should be done regularly. Here are 5 tips for socket weld flange maintenance.

#1 Regularly Inspect Socket Weld Flanges for Damage or Wear

Socket weld flanges should be inspected daily for damage or wear. When socket weld flanges are damaged, the socket and socket weld end separate from each other which causes a loss in pressure control.

#2 Keep Socket Weld Flanges Clean and Free of Debris

Socket weld flanges should be kept clean and free of any debris. This will ensure socket weld flange performance is not hindered.

#3 Check for Leaks Around the Socket Weld Flange Connection

It is important to check socket weld flanges for any leaks. Leaks will cause a reduction in the pressure regulating capabilities of socket weld flanges.

#4 Make Sure the Gasket Is in Good Condition and Properly Seated

The socket gasket is what separates the socket and socket weld flange. If the gasket is not in good condition or it is not properly seated, socket weld flanges will be unable to regulate pressure.

#5 Tighten Bolts to the Recommended Torque Specs

Bolts should be tightened to the socket weld flange manufacturer’s recommended torque specs. If bolts are not tightened correctly, socket weld flanges will leak or may cause a decrease in pressure regulation.

11. Final Words

The socket weld flange has many benefits that make it an excellent choice for connecting pipe fittings.

Socket weld flanges are made from quality materials like carbon steel or stainless steel, which means they will last for years without corroding or rusting. You won’t need to worry about replacing them any time soon! Get started today by browsing our inventory online at Oflange!