PRODUCT FEATURES

SORF Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

A Comprehensive Guide to SORF Flange

When you are looking to purchase a flange, whether it is for piping or another purpose, you will likely come across the term “SORF.” But what is SORF flange?

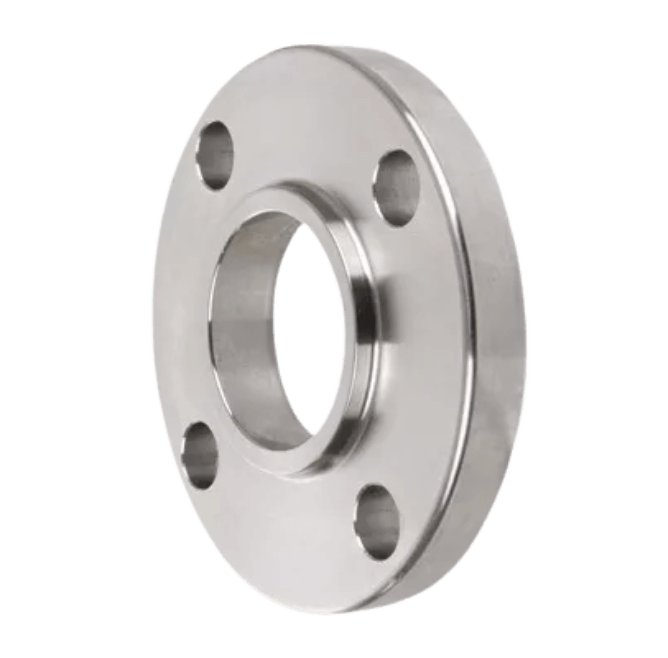

SORF flange is a specialized type of flange that has a unique design and offers certain benefits over traditional flanges. Piping flanges are common fixtures in many industrial and manufacturing settings. They are used to join sections of pipe together, and they come in a variety of sizes and shapes.

In this article, we will discuss what SORF flange is, how it is different from other types of flanges and what are the benefits of using it. So let’s get started!

Table of contents

1. What Is a SORF Flange and Its Uses

SORF flange is a specialized type of flange that has a unique design and offers certain benefits over traditional flanges. SORF flange is also known as s-flange, submittal flange, slip-on raised face flange or raised face slip on flange.

Steel slip on flanges are a common form of pipe flange. This flange stainless steel slip accepts pipe into the bore/center of the flange for welding around both the pipe’s outer diameter and the connection’s interior side.

Some types of this are the stainless steel slip, carbon steel slip, alloy steel slip, Inconel slip and super duplex steel slip.

A SORF flange is a type of flange that is used to join two pipes together. It is typically used in applications where the pipes need to be rotated. The SORF flange has a hole in the middle that allows the pipes to rotate freely.

It has available in different sizes and shapes. The most common SORF flange dimensions are 12 inches, but they are also available in other sizes such as 16, 18 and 24 inches. The shape of a SORF flange can be round, octagonal or square.

SORF flanges are made of steel, cast iron or ductile iron. They can be manufactured from different materials depending on the application. For example, sorf flanges used in oil refineries will likely be made of stainless steel because of its corrosion resistance.

Uses of SORF flange:

- Used in the automotive industry to connect the exhaust system to the engine.

- Used in the plumbing industry to join two pipes together.

- Used for joining ductwork together.

2. How To Select the Right Size SORF Flange

Selecting the right size of SORF flange can be tricky and crucial at the same time because if it’s not the right size, it might not fit or work properly. Here are some ways how to select the right size of SORF flange:

Measure the Flange Diameter and Thickness of the Pipe

It is better to measure the flange diameter and thickness of the pipe using a tape measure or a SORF gauge. This is because flanges come in both standard and metric dimensions, thus it is better to measure the flange full form diameter and thickness of the pipe as accurately as possible.

Check if the SORF Flange Has an Undercut

It is important to check if SORF flanges have an undercut. If flange has an undercut, then it is a type of SORF flange. The SORF refers to the raised face flanges that helps seal the joint between two pipes or fittings.

Determine the Pressure Class

If SORF flange is made of stainless steel or carbon steel, flange may have an SSPC (standard pressure class) or HDPE (high-density polyethylene). The higher the pressure class, the more secure the flange will be under high pressure.

3. Manufacturing Process of a SORF Flange

SORF flange is carefully manufactured to meet the required specifications. Each flange goes to a series of quality checks to ensure that it meets the industry standards. Here is a step by step guide on the manufacturing process of a SORF flange.

Step #1 Cutting of Raw Materials

The SORF flange is manufactured using several different materials. It can be made of steel, cast iron or ductile iron. The flange needs to be flame cut according to the manufacturer’s specifications before it is machined and welded together with other parts of flange assembly.

Step #2 Heating in High Temperature

The SORF flange needs to be heated at high temperature. The flange must be consistent and uniform surface finished during this process as it will help keep SORF flange from leaking under pressure.

Step #3 Forging

The SORF flange is forged in a press. This will help to achieve the desired shape and size for the flange.

Step #4 Machining

The SORF flange is then machined using CNC machines. The holes are drilled and the SORF flange is precision-machined to ensure that it has right shape and size for flange to perform its function effectively.

Step #5 Welding

The SORF flange is welded together with other parts of Aflange assembly using the TIG welding process. This will help to achieve the desired strength and durability for the flange.

Step #6 Testing

The SORF flange is then tested for leaks and other defects before it is sent to the customer. It is important to test the flange under pressure to ensure that it meets the requirements.

Step #7 Packaging and Delivery of the SORF Flange

The SORF flange is then packaged and delivered to the customer. It is important to note that flanges are heavy and bulky, so they will require a lot of space during transportation.

4. Types of SORF Flanges

There are different types of SORF flanges to choose from. They differ from each other in terms of their design and construction. Here are the types of SORF flanges:

Slip-On Flange

This refers to a type of flange that has an internal recess or lip which is used for fastening two pipes together. The slip-on flange is commonly made from stainless steel, carbon steel and ductile iron.

Weld Neck Flange

Weld neck flange is a type of SORF flange that has a long tapered neck. The purpose of this neck is to provide a large welding surface for the attachment of the pipe. The weld neck flange is commonly made from stainless steel, carbon steel and ductile iron.

Lap Joint Flange

Lap joint flange is type of SORF that has a flat face and an internal recess or lip which allows it to be fastened onto another pipe. The lap joint flange is commonly made from stainless steel, carbon steel and ductile iron.

Socket Welding Flange

Socket weld flange is a type of SORF flange that has a circular recess that allows it to be welded to the pipe. Th

Screwed Flange

This screwed flange refers to a type of SORF that has a threaded hole in the center of its face which allows it to be fastened onto another pipe. The screw flange is commonly made from stainless steel, carbon steel and ductile iron.

Threaded Flange

The threaded flange is a type of SORF that has a threaded hole in the center of its face which allows it to be fastened onto another pipe. The threaded flange is commonly made from stainless steel, carbon steel and ductile iron.

Blind Flange

A blind flange is a type of SORF that has an internal recess or SORF which allows it to be fastened onto another pipe. The blind flange is commonly made from stainless steel, carbon steel and ductile iron.

Orifice Flange

The orifice flange is a type of SORF that has a hole in the center of its face which allows fluids to flow through it. The orifice flange is commonly made from stainless steel, carbon steel and ductile iron.

Pipe Flange

Pipe flanges is a type of SORF that has a hole in the center of its face which allows it to be fastened onto another pipe. The pipe flange is commonly made from stainless steel, carbon steel and ductile iron.

Ring Type Joint Flange

Ring type joint flange is a type of SORF that has a circular recess which allows it to be bolted to another pipe. The ring type joint flange is commonly made from stainless steel, carbon steel and ductile iron.

5. Importance of Proper Installation of a SORF Flange

A SORF flange is an important piece of equipment for structural engineering. The flange must be installed properly to avoid any problems with your piping process.

When installing a SORF flange, it is important to make sure that the gaskets are properly aligned. If they are not aligned correctly, it can cause several problems, including leaks and poor performance.

Additionally, you will want to be sure that the bolts are tight enough so that there is no leakage but not so tight that they strip the threads. To ensure that the SORF flange is installed properly, we recommend following these helpful ways:

Remove Existing SORF Flange

First, remove any existing SORF flanges from your piping. We recommend using a flathead screwdriver or other tool to loosen and remove the SORF flanges. If there are still some attached after removing them, you may use pliers to remove them.

Clean the Surface

Next, clean the area where the SORF flange will be installed. We recommend using a degreaser or other cleaning agent to clean the surface. This will help ensure that no dirt or grease present could interfere with the installation.

Install the SORF Flange

Once the surface is clean, you can begin installing the SORF flange. Be sure to use the correct gaskets and bolts for your SORF flange. If you are not sure which parts to use, please consult the manufacturer’s instructions.

Check for Leaks

Once the SORF flange is installed, it is important to check for leaks. To do this, we recommend using a soapy water solution (do not use dish soap) and filling the SORF flange with water. If any bubbles appear, you will need to tighten or loosen the flange until they disappear completely.

Test It Out

Once you have installed your SORF flange properly, it is important to test it out before using it. To do this, we recommend filling th flange with water and running it through. This will help to make sure that there are no leaks present or other issues before you start using the flange.

Check Regularly

Once everything is installed, it is important to periodically check on your SORF flanges to ensure that they are still functioning properly. If you notice any leaks, it is important to address them as soon as possible.

A SORF flange is a critical piece of equipment for any structural applications. By following these ways, you can ensure that your flange is installed correctly and will function properly for years to come. You may also visit our website at Oflange to check how to properly install a SORF flange.

6. Common Problems With a SORF Flange and Their Solutions

Installing flanges can be very tricky, and it is not uncommon for people to run into some problems. Here are a few of the most common problems and their solutions:

Leaks

Leaks can occur at the gasket or bolts. Solutions include replacing the gasket, tightening the bolts and using sealant.

Rust

Rust can form on the SORF flange if it is not properly maintained. Solutions include cleaning the flange and applying a coat of paint or another coating.

Corrosion

Corrosion can occur if the SORF flange is exposed to moisture. Solutions include using a corrosion-resistant material and coating the flange with a protective layer.

Warping

Warping can occur if the SORF flange is not properly supported. Solutions include using proper supports and ensuring that all are properly secured.

7. Benefits of Using SORF Flange

Flanges are an essential tool for the piping industry. Without these, it would be very difficult to connect pipes. There are many benefits of using SORF flanges. Some of the most notable benefits include:

| No. | Benefits |

|---|---|

| 1 | Lower Installation Cost |

| 2 | High-Pressure Resistance |

| 3 | Better Leaking Proof |

| 4 | Easy to Maintain |

| 5 | Variety of Applications |

| 6 | Wide Range of Sizes |

Lower Installation Cost

The SORF flange can be installed quickly and easily, which reduces the installation cost.

High-Pressure Resistance

The SORF flange is resistant to high pressure, which makes it ideal for use in high-pressure applications.

Better Leaking Proof

The SORF flange has a lower leak rate than other types of flanges. It helps prevent leaks by sealing the space between two pipes. It also helps to reduce noise and vibration.

Easy to Maintain

It is easy to install and maintain. It can be installed by anyone with basic knowledge of plumbing tools and materials. It requires minimal maintenance compared to other types of flanges.

Variety of Applications

The SORF flange can be used in a variety of applications, including plumbing, petrochemical and manufacturing industries. It is also suitable for use in residential and commercial buildings.

Wide Range of Sizes

The SORF flange is available in a wide range of sizes to meet the needs of different applications. It is available in sizes ranging from ½ inch to 72 inches.

8. How To Install a SORF Flange

Pipes and flanges are commonly used in many industries, such as construction, plumbing and petrochemical. A SORF flange is a type of flange that is specifically designed for use with pipes. It is important to install the flange properly so that it can function correctly and safely.

Here are the steps on how to install a SORF flange:

Step #1 Make Sure Pipes are Clean

Before installing the SORF flange, make sure that the pipes are clean and free of any debris.

Step #2 Install the SORF Flange

Install the SORF flange using the bolts and washers. Tighten the bolts using a wrench until they are snug but do not over tighten them.

Step #3 Check For Leaks

Fill the SORF flange with water and check for leaks. If any bubbles appear, you will need to tighten or loosen the flange until they disappear. You may also need to use a pipe wrench to ensure that the flange is properly seated.

Step #4 Apply Coat Paint

Once the SORF flange is installed and leak-free, apply a coat of paint or other coating to protect it from rusting.

That’s all there is to it! With a SORF flange installed, you can rest assured that your pipes are securely sealed.

9. 3 Tips for Maintaining Your SORF Flange

Maintaining SORF flange can be very simple and sometimes only requires a quick cleaning. To have a flange that functions properly and lasts for a long time, here are the tips on maintaining your SORF flange.

#1 Clean the SORF Flange Regularly

Clean the SORF flange regularly to remove any dirt, grease or other debris. This will help prevent rust and corrosion from forming.

#2 Apply a Coat Paint

Paint or other coatings can be applied to the SORF flange to protect it from rust and corrosion.

#3 Use a Corrosion-Resistant Material

If the SORF flange is going to be exposed to moisture, use a corrosion-resistant material to prevent rust and corrosion from occurring.

10. Conclusion

SORF flange fittings are used in a variety of piping applications. They provide an efficient and economical way to join two pieces of pipe together. Because SORF flanges are so versatile, they can be used with a variety of materials, including plastic, metal, and rubber.

If you need to find out more about this type of flange or have any questions, please do not hesitate to contact us at Oflange. We would be happy to help!