PRODUCT FEATURES

Lap Joint Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

Lap Joint Flange: All You Need To Know

If you’re in the business of manufacturing or installing piping systems, then you need to be familiar with lap joint flanges.

These flanges are used to connect two pipe segments together, and they provide a reliable and leak-resistant seal.

In this article, we’ll take a closer look at lap joint flanges and explore some of the key features that set them apart from other types of flanges. We’ll also discuss when it’s appropriate to use them and how to install them correctly. So if you’re interested in learning more about this important piece of plumbing hardware, read on!

Table of contents

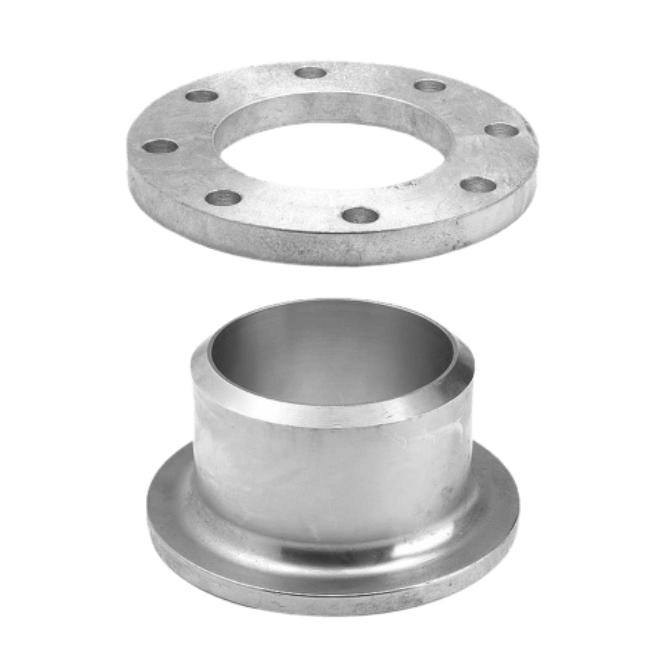

1. Lap Joint Flange Definition and Its Uses

What is a lap joint flange? lap joint flange definition is a type of slip-on flange that can be used to join pre-manufactured pipe segments together. Lap joint flanges provide an effective and reliable seal between the two joined pieces of piping, but they do not prevent rotation.

Flange lap joints can be used in both wet and dry pipelines, though they are most commonly used in dry applications. Lap joint flanges can be made from a variety of materials, such as carbon steel and stainless steel.

2. When to Use a Lap Joint Flange

Lap joint pipe flanges are used when more than one worker needs to work around the piping system.

For instance, you’d probably use this type of flange in an environment that requires people to work on both sides of the piping at the same time. lap joint flange welding is attractive to many companies because it can be quickly and easily installed without any special tools, which reduces labor costs.

This type of slip-on flange is typically used in dry applications where access for inspection and maintenance is needed from both sides of the pipe.

Lap joint pipe flange can also be used for wet applications, but they are not ideal in those situations because the water flow that takes place between the two pipes can cause them to slide out of alignment with one another.

3. Types of Lap Joint Flanges

Lap joint flange types come in a variety of styles and with a wide range of sizes. Lap joint flanges are made with threaded holes on the outside diameter of the flange, so they can be connected to piping on either side.

Lap joints are available in sizes ranging from 2 inches to 20 inches. Lap joints are also manufactured with different thicknesses of metal, which affects their weight and strength.

Here’s a list of some of the most common types of lap joint flanges:

Lap Joint Type A

It is used for flanges with threaded holes on both sides.

Lap Joint Type B

It is used for flanges with threaded holes on only one side.

Lap Joint Type C

It is used for flanges that have no threaded bolt holes, which means the lap joint flange installation without any tools.

To know more about the lap joint flanges and other types of flange, please refer to this video.

4. Styles of Lap Joint Flanges

Lap joints also come in two different styles: Rigid and Flexible. For more detailed information about these two, read below:

Rigid Lap Joint

A rigid lap joint stub end offers a durable connection that won’t flex or distort when exposed to various types of loads. Because the pipes are joined together at the same angle, rigid lap joints allow for easy installation and removal when repairs need to be made.

Flexible Lap Joint

A flexible lap joint flange is better suited for applications where the two sides of piping can shift or move when in use. This type of flange allows some flexibility, though it doesn’t offer as much resistance to deformity as a rigid lap joint.

5. Advantages and Disadvantages of Lap Joint Flange

Lap joints have several key advantages that make them attractive to both contractors and inventors. But, they also have several key disadvantages that you should consider before using these flanges on your project.

Lap Joint Flange Advantages

- Lap Joint flanges don’t require any special tools to install, which reduces labor costs for many companies because it also cuts down on the time required to implement this type of flange.

- Lap Joints are made from materials that won’t corrode or rust, so they can be used in both wet and dry pipelines with confidence.

- Lap Joints allow for a secure connection between two pipe segments without creating a seal, so there is little risk freshwater will get into your system if these pipes spring a leak.

- Lap joints provide an effective way to connect pre-manufactured piping systems quickly and easily; this means you can avoid spending time waiting for a manufacturer to create a custom-sized flange.

Lap Joint Flange Disadvantages

- Lap joints offer little in the lap joint flange weight support; even the largest lap joint flange is designed for use with piping that has an outside diameter no greater than five inches.

- Lap joints aren’t meant to bear heavy loads, which means they’re not ideal for use with pressure pipelines such as those used in oil and gas extraction applications.

- Lap joints also don’t provide any protection from corrosion or rust; if you want to prevent water from entering your system through damaged pipes, this type of connection is not the best choice.

- Lap Joints are known for their relative ease of installation and removal, but Lap Joint flanges tend to be less effective when it comes to anchoring each pipe securely in place.

- Lap joints are also more expensive than other types of connections for pipelines that have an outside diameter greater than five inches.

| ADVANTAGES | DISADVANTAGES |

|---|---|

| Reduces labor costs | Offer little in the lap joint flange weight support |

| Made from materials that won’t corrode or rust | Aren’t meant to bear heavy loads |

| Secure connection between two pipe segments without creating a seal | Don’t provide any protection from corrosion or rust |

| Provide an effective way to connect pre-manufactured piping systems quickly and easily | Tend to be less effective when it comes to anchoring each pipe securely in place |

| More expensive than other types of connections for pipelines | |

6. Step by Step Guide of Lap Joint Flange Manufacturing Process

Below is a step-by-step guide in Lap Joint Flange Manufacturing

Step#1 Cutting Metal Lap

In the Lap Joint Flange manufacturing process the first step is to use a plasma cutter or an oxy-fuel flame to cut two plates from a flat sheet of metal. Lap joints are typically manufactured with either mild steel, stainless steel, or alloy steel depending on design and function.

Step#2 Joining Lap Joints

The second step in the Lap Joint Flange manufacturing process is to drill a hole through each of the plates you cut in step one. This hole must be slightly larger than the diameter of the pipe being used to create lap joints.

Step#3 Riveting Lap Joints Together

The third step in the Lap Joint Flange manufacturing process is using an automated press to attach the two plates from step two together along their long dimension. This will create a Lap Joint Flange that is less than half an inch thick and around one foot wide.

Step#4 Lap Joint Together

The next step in the Lap Joint Flange manufacturing process is to drive a punch through the drilled holes from Step two using a hydraulic press. This will create Lap Joints on each plate; Lap flanges are often used by inventors because this process can be repeated to make Lap Joints of various sizes.

Step#5 Finishing Lap Joint Flange

The final step in the Lap Joint flange manufacturing process is using a grinder to remove any excess metal that remains on Lap Joint Flange from step four.

Lap Joints need to be smaller than their connecting pipe segments to create a tight fit between them, so joints must be shaped slightly differently depending on the size of the lap Joint and the outside diameter of the pipe being joined together.

7. Lap Joint Flange Cost

Lap Joint Flange average cost can vary depending on the size and type of metal used in their construction.

Lap Joint Flanges that are made from stainless steel tend to be more expensive than those made from mild steel, and Lap Joint Flanges that are larger than five inches in diameter will also be more expensive than those that are smaller.

Lap Joint Flanges manufactured by automated lap joint flange assembly lines can be purchased for an average of $30-40 dollars per piece and up. The Lap Joint Flange is more expensive than other types of pipe connections because it requires the use of automated equipment to complete Lap joint flanges quickly.

Manufacturers often use Lap joint flanges made of steel, aluminum, copper, nickel and other metals Lap joints are easy to install and remove.

Oflange is one of the Lap Joint Flange Manufacturers in China. We provide innovative and high-quality products for use in applications such as pipeline systems, oil wells, gas processing plants, and refineries.

8. 6 Things to Consider When Purchasing Lap Joint Flange

Lap Joint Lap flanges are known for their relative ease of installation and removal. You should consider these 6 things when purchasing Lap Joint Flange:

#1 Lap Joint Flange Size

Check the size of the Lap Joint Flange you need before purchasing any product from Lap Joint Flange suppliers. If the flange is small in size, it should be made of high-quality material so it does not get damaged easily.

#2 Lap Joint Flange Strength

Lap Joint Flange has two types: rigid and flexible. You need to check the strength of the Lap Joint Flange before purchasing Lap Joint Flange. Lap Joint Flange must be strong enough to carry the weight of the pipes, otherwise, Lap Joint Flange will not be able to support those heavy pipelines.

#3 Lap Joint Flange Material

Lap Joint Flange also has two types: Stainless Steel Lap Joint and Alloy Steel Lap joint. Although both materials are good in quality, Lap Joint Flange made of stainless steel is much better in quality than Lap Joint Flange made of alloy steel.

When Lap Joint Flange will be exposed to high temperatures, you need Lap Joint Flange that will not get affected by the temperature changes.

#4 Lap Joint Flange Design

Different Lap joint flanges have different designs and shapes. You need to check whether the lap joint flange design of the Lap Joint Flange fits with your pipe system or not before buying Lap Joint Flange so there are no problems while you use it later on.

#5 Lap Joint Flange Quality

Before purchasing any product online you should always check its quality so there are no complaints after delivery or use of it. Always compare prices between different lap joint flanges suppliers so Lap Joint Flange is best in prices and quality.

Lap Joint Flange with low price may have a lower quality which means Lap Joint Flange will not be durable enough to handle high pressure, so it’s important to check Lap Joint Flange quality before purchasing Lap joint flange from any lap joint flanges suppliers.

#6 Lap Joint Flange Price

The price of a Lap Joint Backing Flange depends on its size, material, design, and quality. Best Lap joint flanges are made of stainless steel and have a unique design while some Lap joint flanges are made of alloy steel and have no unique design.

You need to check the specifications before buying a Lap Joint Flange gasket from any supplier or manufacturer because Lap Joint Flange prices differ from one another.

9. Conclusion

Lap joint flanges are a great way to join two pipes together. They are strong and durable. If you need to join two pipes together, a lap joint flange is the best way to do it.

We hope you find this information helpful. If you are interested in learning more about lap joint flanges or need help deciding if this type of flange is the best option for your project, please do not hesitate to contact us.

Our team would be happy to discuss your needs and provide you with a free quote. Thanks for reading!