PRODUCT FEATURES

UNI Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

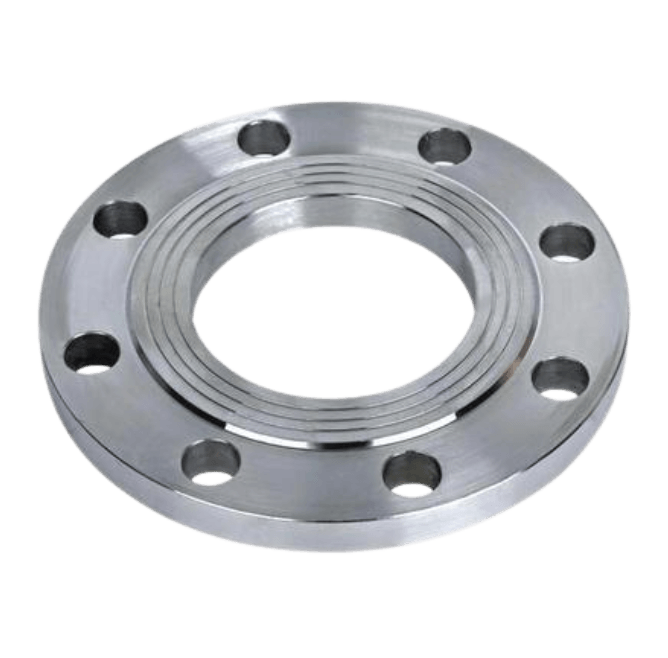

UNI Flange

The UNI flange is a type of flange that can be used in conjunction with pipes and fittings. This type of flange can be used in a variety of applications, including transportation and storage of fluids. The UNI flange is made from high-quality materials and is designed for durability and performance.

UNI flange is also used for box flanges that are used in the construction of machinery, industrial plants, and oil refineries. Metal works use UNI brackets to connect their metal structures.

Table of contents

1. UNI Flange Definition and Its Uses

A UNI flange is a type of flange that is used to join two pipes together. The UNI flange has a single hole in the center that the pipes fit into. The UNI flange is typically made from metal like the adapter flange and is used to connect pipes of different sizes.

The uses of UNI flanges are mainly for uniting or joining pipes together. They can be used in a variety of ways from uniting two pipes to make one larger pipe or uniting more than two pipes together. UNI flange for ductile iron pipe creates a smooth and continuous flow and changes the way water flows through piping.

2. The Benefits of Using a UNI Flange

When it comes to piping, there are a variety of different flanges that can be used for an iron pipe. Among these is the UNI flange. This type of flange is unique in that it has one neck, as opposed to the two that are found on most other flanges.

Because of this, it is not as common as some of the other types. However, there are several benefits to using a UNI flange that makes it worth considering.

Some of the benefits of using a UNI flange include:

Ease of Installation

The UNI flange is very easy to install, which can save time and money. It is also possible to unify two unibodies in different positions with this flange and there’s no need to set screw locking device or use other tools.

Reduce Installation Time and Expense

Being able to unify unibodies in different positions can save a lot of time and money when it comes to piping and unifying your equipment. There’s no need for additional connectors like the ford meter box because the UNI flange unifies the unibody.

Strength and Durability

The UNI flange is very sturdy and durable, meaning that it will last a long time. It also has no weak points, which means that it will be less likely to break when in use and have bolt hole alignment problems.

Safety

The UNI flange is very safe to use, which means that it does not pose any safety risk. It is possible to unify unibodies in different positions with this flange, which is an additional safety benefit.

Versatility

The UNI flange can unify unibodies in almost any position and pipe size, making it very versatile. This allows you to unify equipment that other types of flanges cannot unify because of their orientation or how they unify with equipment.

A UNI flange is an excellent option for anyone who wants their piping and unifying equipment to be easier, quicker, more durable, safer, and more versatile. They’re also an excellent choice if you want unifying unibodies to be easier and more accessible.

For more information on UNI flanges or unifying unibodies, contact us at Oflange today!

3. Step by Step Guide on UNI Flange Installation

When it comes to UNI flange installation, there are a few key steps that you will need to follow to ensure a successful installation.

Here are the UNI flange installation instructions:

Step #1 Measure the Size of the UNI Flange

The first step is to measure the size of the UNI flange and make sure that it is the right size for the pipe. The UNI flange should also be compatible with the type of material that the pipe is made from.

Step #2 Prepare the Pipe for Installation

The next step is to prepare the pipe for installation. This includes cleaning the pipe and removing any burrs or other obstructions. You will also need to make sure that the pipe is properly aligned before you begin installing the UNI flange.

Step #3 Install the UNI Flange

The final step is to install the UNI flange. This can be done using a UNI flange installation tool (e.g., UNI flange adapter or ford flange adapter). In either case, the UNI flange should be installed carefully since it will affect the quality of your installations in the future.

4. The Different Types of UNI Flanges Available on the Market

There are many different types of UNI flanges available on the market, and each one has its own set of benefits and drawbacks. The following are some of the most common types:

| 1 | Weld Neck UNI Flange |

| 2 | Threaded UNI Flange |

| 3 | Slip-on UNI Flange |

| 4 | Socket UNI Flange |

| 5 | Blind UNI Flange |

| 6 | Spectacle UNI Flange |

| 7 | Lap UNI Flange |

| 8 | Flat UNI Flange |

| 9 | Full Face UNI Flange |

| 10 | Back UNI Flange |

| 11 | Low UNI Flange |

| 12 | Swage UNI Flange |

Weld Neck UNI Flange

This type of UNI flange is ideal for high-pressure applications, as it has a thick neck that can withstand a lot of stress. However, it can be difficult to weld, so it’s not ideal for beginners.

Threaded UNI Flange

This type is easy to install and is perfect for use in low-pressure applications. However, it can be more prone to leaks than other types of UNI flanges.

Slip-on UNI Flange

This UNI flange utilizes a gasket, so it can be easily installed without any welding. However, it might not be able to withstand the same level of pressure as other UNI flanges, and it might slip off under high pressure.

Socket UNI Flange

This UNI flange has a tapered end that can be inserted into a socket, which makes it easy to install. However, it’s not recommended for high-pressure applications.

Blind UNI Flange

This UNI flange has no openings or vent holes, so it helps keep the inside of the vessel clean and sanitary while reducing pressure drop. However, it can only be used in low-pressure applications.

Spectacle UNI Flange

This UNI flange has a raised disc that helps reduce pressure drop and improve the flow of liquids through the UNI flange. It’s better for high-pressure applications than most UNI flanges, but it doesn’t work well for low-pressure applications.

Lap UNI Flange

This UNI flange has two openings, so it’s easy to install and use. However, it can be difficult to seal completely for high-pressure applications.

Flat UNI Flange

This UNI flange is flat across the top, which makes it an excellent choice for low-pressure applications. However, it’s not recommended for high-pressure applications.

Full Face UNI Flange

This UNI flange does not have any openings along the sides or top but has a round opening in the middle. It can be used in both high- and low-pressure applications, as it resists leaks well.

Back UNI Flange

This UNI flange has no openings or threads on the end that attach to a vessel. Instead, it has an opening in the back of the UNI flange. It’s not as easy to install as other UNI flanges but is perfect if you need a UNI flange that can only be used with low-pressure applications.

Low UNI Flange

This UNI flange has an opening at the bottom of the UNI flange instead of on top or side. It’s not as popular as other UNI flanges, but it can be used in low-pressure applications.

Swage UNI Flange

This UNI flange is similar to the slip-on UNI flange, but with a threaded neck instead of tapered. It makes it easy to install UNI flanges on vessels or piping systems, but it’s not recommended for high-pressure applications.

5. Applications for a UNI Flange

A UNI flange is a type of flange that is designed to mate with a UNI coupling. UNI flanges are typically used in high-pressure and high-temperature applications. They are also often used in the petrochemical and pharmaceutical industries.

Some common applications for UNI flanges include:

Pipelines

UNI flanges are a popular choice for cementing UNI couplings in pipelines. The UNI flange provides a pressure-tight seal between the UNI coupling and the pipeline.

Pressure Vessels

UNI flanges are used to connect pipes and valves in pressure vessels by soldering. They are primarily found on the outlet of a vessel, where they allow for easy connection to other components, such as UNI couplings or other UNI flanges.

Reactors

UNI flanges are used in reactors to connect pipes and valves, allowing easy separation when unconnected.

Heat Exchangers

UNI flange that mate with UNI couplings can be found on the heating side of heat exchangers. UNI flanges allow for connection of piping without having to rotate or turn components.

Compressors

UNI flanges are often found on the inlet of a compressor, as they allow for connection to other system components.

6. UNI Flange Average Price

The UNI flange is a common type of flange that is used in the piping and tubing industry. The UNI flange is available in a variety of sizes, and it can be used to connect pipes with different diameters. The UNI flange is also available in a variety of materials, including steel, ductile iron, and stainless steel.

Average UNI flange pricing is $2 to $4 per UNI flange unit. The UNI flange price varies based on the material that the UNI flange is made from and its size. A UNI flange with a diameter of 24 inches may cost anywhere from $40 to $80, while UNI flanges with diameters of 36 inches tend to cost between $60 and $120.

If you want an exact UNI flange quote, contact us at Oflange. Our UNI flange professionals will be happy to provide you with a quote based on your needs.

7. Ways to Properly Maintain Your UNI Flange

Proper maintenance of a UNI flange is essential to ensure that it functions as intended and for a longer period. Here are 3 ways to properly maintain your UNI flange:

Always Keep the UNI Flange Clean

The UNI flange should always be kept clean. Use soap and water to clean or any other cleaning supplies that are appropriate for use on UNI flanges available on site, like UNI flange brushes. You can also install UNI flange cleaners.

Make Sure You Dry the UNI Flange Thoroughly After Cleaning It

After you have cleaned the UNI flange and its accessories, make sure that you dry it thoroughly before you store it. The UNI flange should be dried immediately after cleaning to prevent any unnecessary accumulation of dirt and chemicals that can lead to rust.

Replace a Worn Down UNI Flange

If the UNI flange is worn down or if there is any damage to it, it should be replaced immediately. If the UNI flange is not replaced and still used as normal, this will cause unbalanced drilling and will cause other reproductive harm.

8. 3 Tips on How to Choose the Right UNI Flange for Your Needs

When looking for a UNI flange, it is important to keep in mind the purpose of the flange and the type of pipe it will be used with. There are 3 main factors to consider when choosing a UNI flange: size, pressure rating, and material.

Size

The UNI flange should be able to fit the size of the pipe it will be used with. The UNI flange needs to match up closely with the outside diameter of the pipe so that there will not be any unneeded space.

Pressure Rating

When choosing a UNI flange, it is important to consider the pressure rating of the UNI flange. Depending on what will be connecting to the UNI flange, it is important to make sure that there is enough pressure resistance for the UNI flange to handle.

Material

The UNI flange should be made out of the same material as the pipe. If the UNI flange is not made out of the same type of material, there will be a risk that it is weaker than necessary.

To summarize, when looking for a UNI flange consider size, pressure rating, and material to make sure that you have chosen the right UNI flange for your needs.

If you want to know more about pipe flanges, check out this video.

9. Final Words

The UNI flange has been designed to fit seamlessly into your existing system and provide years of reliable service. It’s also incredibly easy to install – just tighten it up with some bolts and you’re good to go! You won’t have any issues using this product because we guarantee its quality 100%.

If you are looking for UNI flanges, please don’t hesitate to contact us at Oflange. Click here right now to get your hands on these high-quality UNI flanges at an incredible price today!