PRODUCT FEATURES

Stainless Steel Pipe Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

A Comprehensive Guide of Stainless Steel Pipe Flange

Selecting the right stainless steel pipe flange can be confusing and overwhelming. There are many different types of flanges available, each with its unique benefits and drawbacks. Without the proper knowledge, it can be difficult to select the right stainless steel pipe flange for your needs.

Stainless steel pipe flange is a type of flange that is made from stainless steel. It is a popular choice for many applications because it is strong and durable. They are available in a variety of sizes and styles, making them a versatile option for many different applications.

In this guide, we will discuss the different types of stainless steel pipe flanges and provide you with tips on how to select the right one for your application. So, read on!

Table of contents

1. What Is a Stainless Steel Pipe Flange and What Are Its Uses

A stainless steel pipe flange is a type of flange that is made from stainless steel. Stainless steel is a type of steel that is known for its corrosion resistance and durability.

Because of this, stainless pipe flange is ideal for use in applications where corrosion resistance and durability are important. Some common applications where stainless steel pipe flanges are used include:

- Chemical processing

- Food and beverage production

- Pharmaceutical production

- Pulp and paper production

- Refining

Stainless steel pipe flanges are also used in the automotive and aerospace industries.

2. How To Identify a Stainless Steel Pipe Flange

When it comes to stainless steel pipe flanges, you must be able to identify them properly. This is because stainless steel pipe flanges play an important role in the overall function of a piping system. Here are some tips on how to identify stainless steel pipe flanges:

Look for the Presence of a Raised Face

The presence of a raised face is one of the easiest ways to identify a stainless steel pipe flange than a weld neck flange. A raised face is essentially a protrusion on the flange that allows it to seat properly against the mating surface.

Check for the Grade Stamp

The stainless steel grade of the flange can be found on a small stamp. This gives you an idea of how strong the stainless steel pipe flange is.

Inspect the Threading

The threading on a stainless steel pipe flange is usually very fine. This makes it less likely to cross-thread when being installed.

Look for the Manufacturer’s Logo

Many stainless steel pipe flanges will have the manufacturer’s logo stamped or engraved into them. This can help determine their authenticity.

By following these tips, you’ll be able to identify a stainless steel pipe flange with ease. Remember, these tips are just a guideline – if you’re still unsure about the identity of a stainless steel pipe flange, don’t hesitate to contact us at Oflange. We’ll be able to help you with any stainless steel pipe flange-related issue.

3. Different Types of Stainless Steel Pipe Flanges

There are different types of stainless steel pipe flanges available in the market. Some of the most common types are:

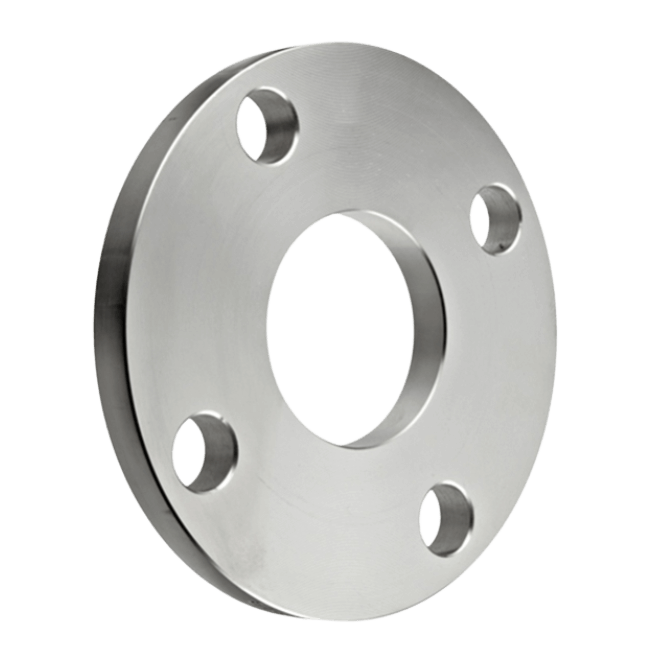

Slip-On Pipe Flanges

These stainless steel pipe flanges have a slip-on end that can easily be attached to the pipe. They do not require any welding or bolting and are perfect for use in low-pressure applications.

Socket Weld Pipe Flanges

These stainless steel pipe flanges have a socket weld end that can be easily welded to the pipe. They are perfect for high-pressure applications and are very strong and durable.

Threaded Pipe Flanges

These stainless steel pipe flanges have threaded ends that can be easily attached to the pipe. They are perfect for use in high-pressure and corrosive environments.

Lap Joint Pipe Flanges

These stainless steel pipe flanges have a lap joint end that can be easily attached to the pipe. They are perfect for use in low-pressure fittings and non-corrosive environments.

Stainless steel pipe flanges are available in a variety of different sizes and materials to suit your pipe size. Make sure to choose the right type of stainless steel pipe flange for your application to ensure optimal performance.

4. How To Install or Remove a Stainless Steel Pipe Flange

Installing or removing a stainless steel pipe flange can seem daunting, but it’s not that difficult.

Here’s how to install a stainless steel pipe flange:

Remove the Old Stainless Steel Pipe Flange

Remove the stainless steel pipe from the old stainless steel pipe flange by unscrewing it with adjustable pliers. Leave the stainless steel pipes in place, as they will be reused for your new stainless steel pipe flange installation.

Use Flange Removal Tools to Remove the Old Stainless Steel Pipe Flanges

You may have stainless steel pipe flanges that are welded to stainless steel pipes. This happens when stainless steel pipe flanges and stainless steel pipes are installed together. You’ll need a chisel and hammer or other tool designed for removing stainless steel pipe flanges.

Install the New Stainless Steel Pipe Flange

Attach the stainless steel pipe flange to stainless steel pipes with stainless steel pipe and bolts. Use a torque wrench to tighten stainless steel pipes very securely, but not too tight, as you can distort stainless steel and damage them.

How to remove a stainless steel pipe flange:

Remove Stainless Steel Bolts

Remove the stainless steel bolts that hold the stainless steel pipe flange in place. You may need a socket wrench to do this.

Use a Chisel and Hammer or Other Tool Designed for Removing Stainless Steel Pipe Flanges

If the stainless steel pipe flange is welded to the stainless steel pipes, you’ll need to use a chisel and hammer or other tool designed for removing stainless steel pipe flanges to remove it.

Clean the Threads on the Stainless Steel Pipes

Clean the threads on stainless steel pipes with a wire brush. This will ensure that the new stainless steel pipe flange is installed properly and won’t leak.

Install Stainless Steel Pipe Flange

Install stainless steel pipe flange on stainless steel pipes. Use a torque wrench to tighten stainless steel bolts very securely, but not too tight, as you can distort stainless steel and damage them.

5. Factors Need To Be Considered When Selecting a Stainless Steel Pipe Flange

When selecting a stainless steel pipe flange, the following factors should be considered:

#1 The Type of Stainless Steel Being Used

Various types of stainless steel have different properties and are suitable for different applications.

#2 The Size and Weight of the Flange

Larger flanges can be more difficult to handle and install, and heavier flanges can require more robust support structures.

#3 The Pressure Rating of the Flange

The higher the pressure rating, the greater the load that the flange can withstand. It is important to note that stainless steel pipe flanges have pressure ratings following the ANSI B16.34 standard.

#4 The Type of Connection Required

Some flange connections are easier to use than others. It is important to select the type of connection that will be easiest to use in the specific application.

#5 The Environment in Which the Flange Will Be Used

Some environments can be more corrosive than others. It is important to select stainless steel pipe flanges that are compatible with the specific application environment.

6. Manufacturing Process of a Stainless Steel Pipe Flange

The manufacturing process of stainless steel pipe flange is long and intricate. Below is the process of how it’s done.

| 1 | Selection of Raw Materials |

| 2 | Cutting of Raw Materials |

| 3 | Forming of Pipe Flange Parts |

| 4 | Welding of Pipe Flange Parts |

| 5 | Finish Machining of the Stainless Steel Pipe Flange |

| 6 | Quality Checks |

Step #1 Selection of Raw Materials

The stainless steel pipe flange requires stainless steel of high quality. The stainless steel is selected after several analyses and tests to ensure it meets the standards set by the American Society for Testing and Materials (ASTM).

Step #2 Cutting of Raw Materials

Stainless steel pipe flange manufacturers cut stainless steel from a large piece into smaller pieces that are required to make flanges. The stainless steel is cut using a CNC machine that ensures precision and accuracy in the cutting process.

Step #3 Forming of Pipe Flange Parts

After the stainless steel has been cut, it undergoes various forming processes until it takes the shape of a pipe flange part. This process includes punching, drawing, and bending.

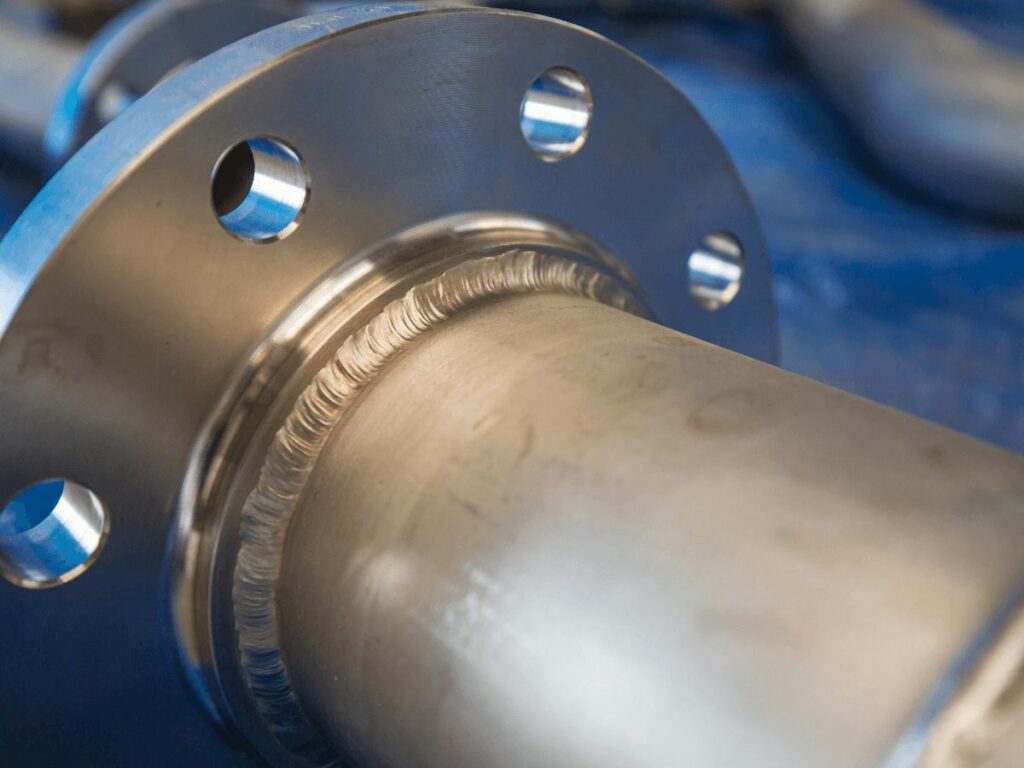

Step #4 Welding of Pipe Flange Parts

The pipe flange parts are then welded together using TIG welding. This type of welding is used to join stainless steel because it leaves a clean and strong weld.

Step #5 Finish Machining of the Stainless Steel Pipe Flange

The stainless steel pipe flange is then finish machined to ensure that it has a smooth surface. This process is important to ensure the stainless steel pipe flanges dimensions and specifications are met as per ASTM standards.

Step #6 Quality Checks

After all these processes, stainless steel pipe flange manufacturers perform quality checks at each stage of production to ensure that there are no defects in the stainless steel pipe flanges they manufacture.

7. 4 Tips on Cleaning and Maintaining a Stainless Steel Pipe Flange

When it comes to stainless steel pipe flange, cleaning and maintaining it is important. Here are 4 tips to help you out:

#1 Clean the Flange Regularly

You must clean the stainless steel pipe flange regularly. This will help prevent any build-up from occurring and will also keep it looking as good as new.

#2 Use Stainless Steel Cleaner and Polish

If you are cleaning stainless steel pipe flange, then you must use stainless steel cleaner and polish to clean it with. This will help protect the finish on your stainless steel pipe flange for much longer than if you just used water or soap alone.

#3 Don’t Use Abrasive Materials To Clean It

When cleaning stainless steel pipe flange, you should never use any abrasive materials. This can cause damage to the surface of the flange and will end up making it look worse than before.

#4 Store It in a Dry Place

Finally, stainless steel pipe flange should always be stored in a dry place. This will help prevent rust from forming and it will also keep the stainless steel cleaner for much longer than if you store it somewhere damp or humid.

8. Specifications of a Stainless Steel Pipe Flange

The stainless steel pipe flange has a variety of specifications that must be met to ensure proper functioning and compatibility. To make sure that you are ordering the right stainless steel pipe flange for your needs, it is important to be familiar with these specifications.

Some of the key specifications to consider include:

Size of the Flange

The size of the flange is important to consider because it will determine how well it fits onto the pipe. Additionally, the size of the flange will also impact the weight and overall strength of the flange.

Type of Connection

There are a variety of different types of connections that can be made with stainless steel pipe flanges. The most common type of connection is the threaded connection, which uses screws to attach the flange to the pipe. Other types of connections include welded and socketed connections.

The Pressure Rating

The pressure rating of a stainless steel pipe flange is the maximum amount of pressure that the flange can withstand. It is important to select a stainless steel pipe flange with a pressure rating that is greater than the maximum pressure that will be exerted on it.

The Material Grade

The material grade of a stainless steel pipe flange is important to consider because it will impact the strength and durability of the flange. To ensure that you are selecting a durable and strong stainless steel pipe flange, be sure to select one with a high-quality material grade.

These are just some of the key specifications to consider when purchasing a stainless steel pipe flange. By familiarizing yourself with these specifications, you can be sure to select the right flange for your needs.

9. Benefits of using a Stainless Steel Pipe Flange

When it comes to industrial piping, stainless steel flanges are a popular choice for a variety of reasons. Here are just a few benefits of using stainless steel pipe flanges:

Strength and Durability

Stainless steel is a strong material that can withstand a great deal of wear and tear, making it ideal for use in industrial applications.

Corrosion Resistance

SS pipe flanges are highly resistant to corrosion, making them a wise choice for applications that may be exposed to moisture or other elements that could cause damage.

Versatility

Stainless flanges can be used in a variety of piping applications, making them an extremely versatile option.

Long Lifespan

With proper care, ss flange can last for many years, making them a wise investment. It is important to select a stainless steel pipe flange that is made with high-quality materials to ensure its long lifespan.

When it comes to stainless steel pipe flanges, there are many benefits to consider. If you need a quality flange for your industrial piping needs, stainless steel is the way to go. Contact us today at Oflange to learn more about our stainless steel pipe flanges.

Oflange is a global manufacturer of pipe flanges and has been in business for several years. We provide innovative and high-quality products for use in applications. Our mission statement is to manufacture high-quality, durable, and affordable products that will serve the needs of our customers.

10. Conclusion

Stainless steel pipe flanges are a great way to connect two pipes. They are made of stainless steel, so they are durable and resistant to corrosion. There are many different types of stainless steel pipe flanges, so you can find the perfect one for your needs.

Contact us at Oflange today if you are in search of a stainless steel pipe flange. Our experts will help you find the perfect one for your needs.