PRODUCT FEATURES

Stainless Steel Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

Stainless Steel Flange: Everything You Need to Know

You’ve probably heard that stainless steel flanges are a great choice for piping, but you may not know why. A lot of people choose stainless steel flanges because they’re strong and durable. But there are other reasons to choose them too.

A stainless flange is a type of flange that is made from stainless steel. It is often used in industries where durability and resistance to corrosion are important, such as the food and beverage industry.

If you are looking for stainless flanges, you have come to the right place. In this blog post, we will talk about stainless steel flange and everything that you need to know about it. Keep reading!

Table of contents

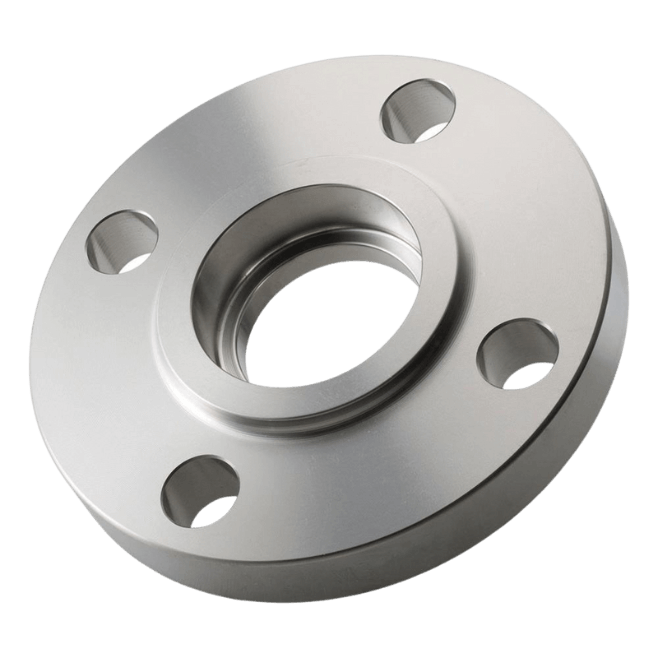

1. What Is a Stainless Steel Flange and Its Uses

A stainless steel flange is a type of flange that is made from stainless steel. It is used to connect two pipes or tubes. The stainless steel flange is bolted to the pipe or tube, and the other pipe or tube is then bolted to the stainless steel flange. This creates a watertight seal between the two pipes or tubes.

Flanges stainless steel is used in a variety of applications, including plumbing, HVAC, and industrial applications. It is also used in the food and beverage industry. The stainless steel flange is corrosion-resistant, which makes it a good choice for these industries.

There are available varieties of stainless steel flange sizes and thicknesses. It is also available in a variety of shapes, including round, square, and rectangular. Additionally, the stainless steel flange HS code is 73072100. This is used by the customs authority to classify stainless steel accessories.

2. Choosing the Right Stainless Steel Flange for Your Needs

When it comes to stainless steel flanges, there are a few things you need to consider before making a purchase. Below are a few factors to think about:

Size and Weight

Stainless steel flanges come in a range of sizes. Measure your ss pipe flanges and determine the size before making a purchase. You should also consider the stainless steel flange weight. You can use a stainless steel flange weight calculator.

Pressure Rating

Stainless steel flange ratings are rated by pressure class, which is indicated with numbers (e.g., 150, 300, or 600). You also need to consider the maximum operating temperature of stainless steel flanges.

Connections

Stainless steel flanges come with a variety of connection types, including welding neck, slip-on, socket weld, and threaded. Choose the type that will work best for your application.

If you’re still unsure which stainless steel flange is right for you, contact the experts at Oflange. We’ll help you find the perfect flange for your needs.

3. Stainless Steel Flange Price

The SS flange price is always a consideration. And, rightly so – after all, you don’t want to spend too much on something that you don’t need. However, it’s important not to sacrifice quality to save a few bucks.

Below are the average stainless steel flange (SS flange) prices:

| Type | Price |

|---|---|

| Stainless Steel 316, A182 Slip On Flange | $100.00-$200.00 |

| Stainless Steel 316L, Blind Raised Face Flange | $150.00-$300.00 |

| Stainless Steel 304, Weld Neck Flange | $50.00-$200.00 |

| Stainless Steel 304L, Lap Joint Flange | $30.00-$100.00 |

| Stainless Steel 321, Threaded Flange | $25.00-$75.00 |

| Stainless Steel 316, Threaded Flange | $30.00-$150.00 |

These are just general stainless steel flange price lists, this may vary depending on the SS flange manufacturer so please contact us at Oflange to get a free quote.

4. Benefits of Using a Stainless Steel Flange

There are many benefits to using a stainless steel flange. Some of these benefits include:

Strength

Stainless steel flange material is very strong, making it ideal for use in flanges. This strength ensures that the flange will not break or crack, even under heavy loads.

Corrosion Resistance

Stainless steel is highly resistant to corrosion, meaning that it will not rust or corrode over time. This makes the stainless steel flange a more durable option than other materials.

Temperature Resistance

Stainless steel also has a high resistance to heat, meaning that it can withstand high temperatures without melting or warping. This makes the stainless steel flange a great choice for applications where high temperatures are present.

Overall, the stainless steel flange is a great choice for any application where strength, corrosion resistance, and temperature resistance are needed. It is a durable and long-lasting option that can provide peace of mind in tough environments.

If you’re looking for a stainless steel flange, be sure to check out our stainless steel flange selection at Oflange. We offer a wide variety of stainless steel flanges in a variety of sizes and configurations, so you can find the perfect option for your needs.

5. Installation of a Stainless Steel Flange

A stainless steel flange is a type of connector that is commonly used in piping and plumbing systems. It is a disk-shaped fitting that has a threaded hole in the center, which allows it to be attached to other stainless steel flanged fittings dimensions.

Here’s how to install stainless steel flanges:

Identify the Correct Size

To install a stainless steel flange, you will need to first identify the correct size for your application. The flange should be the same size or slightly larger than the pipe or tubing that it will be connecting.

Clean the Surface of the Pipe or Tubing

Once you have identified the correct size, you will need to clean the surface of the pipe or tubing where the flange will be attached. Make sure that there is no dirt, grease, or other contaminants present, as these could interfere with the seal.

Install the Flange on the Pipe or Tubing

Once you have cleaned the pipe or tubing, you will simply need to attach the stainless steel flange. You can do this by using stainless steel screws and a wrench (or other appropriate tools). Make sure that all of your screws are tight before moving on to step four.

Test for Leaks

Once the stainless steel flange is installed, it’s important to test for leaks. You can do this by filling the pipe or tubing with water and checking for any leaks. If you find any leaks, make sure to tighten the screws on the flange until they are tight.

Now that you know how to install stainless steel flanges, you can confidently tackle any piping or plumbing projects that come your way!

For more information on stainless steel flanges, visit our Oflange website today. We carry a wide variety of stainless steel flanges in a variety of sizes to meet your needs.

6. 3 Tips for Maintenance and Cleaning of Stainless Steel Flanges

Stainless steel flanges are susceptible to corrosion and should be cleaned regularly. To maintain your stainless steel flange, follow these 3 simple tips:

#1 Clean Your Stainless Steel Flange With a Stainless Steel Cleaner

Stainless steel flanges should be cleaned with a stainless steel cleaner to remove any built-up residue or corrosion. Make sure to read the manufacturer’s instructions for your stainless steel cleaner to avoid any damage to your flange.

#2 Avoid Using Harsh Chemicals or Abrasive Materials To Clean Your Stainless Steel Flange

Harsh chemicals or abrasive materials can damage the stainless steel and cause corrosion. Instead, use a stainless steel cleaner or a gentle scrub brush to clean your flange.

#3 Store Your Stainless Steel Flange in a Dry Place When Not in Use

Stainless steel flanges should be stored in a dry place when not in use to prevent corrosion. If they are stored in a humid environment, the stainless steel will corrode and your flange will need to be replaced.

By following these simple tips, you can maintain your stainless steel flange and keep it looking new for years to come!

7. Manufacturing Process of Stainless Steel Flanges

Stainless steel flange manufacturer follows a certain process to manufacture stainless steel flanges. The steps involved in the manufacturing process are as follows:

Step #1 Selection of Raw Materials

The manufacturing process begins with the selection of raw materials and the stainless steel flange material specification. The stainless steel is melted in a furnace and poured into a mold. The molten stainless steel is then allowed to cool and solidify. This process creates the stainless steel flange blank.

Step #2 Machining of the Flange Blank

The next step in the manufacturing process is the machining of the flange blank. The machining process includes the drilling of the holes and the cutting of the flange radius. The finished product is then polished to remove any surface defects.

Step #3 Final Assembly

The stainless steel flange is then ready for final assembly. The flange is welded to the pipe and then pressure tested. Finally, the finishing touches are applied including painting, labeling, and packaging.

8. Top Stainless Steel Flange Manufacturer

When it comes to purchasing, you want to make sure that you’re dealing with a reputable stainless steel flanges manufacturer. Here are 4 of the top stainless steel flange manufacturers in the industry:

Oflange

Oflange is a global manufacturer of pipe flanges and has been in business for several years. We provide innovative and high-quality products for use in applications such as pipeline systems, oil wells, gas processing plants, and refineries.

Our mission statement is to manufacture high-quality, durable, and affordable products that will serve the needs of our customers.

We offer a wide variety of products, including:

- Flange bolts and nuts

- Pipe flanges in various sizes and materials (steel or stainless steel)

- Steel piping systems for use in commercial and industrial facilities

- Stainless steel piping systems for use in commercial, residential, and industrial facilities.

Parker Hannifin

Parker Hannifin is a Fortune 200 company that has been in business for over 100 years. They are a leading manufacturer and stainless steel flange distributor of motion and control technologies and products, providing solutions for a wide range of markets and applications. Some of their products include:

- hydraulic systems

- pneumatics

- filtration

- seals

- stainless steel flange ball valve

Some of their product offerings are stainless steel flanges and a stainless steel exhaust flange. Stainless steel flanges are made from 304 or 316 stainless steel, which makes them corrosion-resistant and ideal for many applications.

They have a variety of sizes and a stainless steel flange pressure rating to choose from, making them a versatile option for many projects.

John Crane

John Crane is a manufacturer of stainless steel flanges. They have been in business for over 100 years and are a trusted name in the industry. Their products are made from high-quality stainless steel and are designed to meet the most rigorous demands.

John Crane offers a wide range of stainless steel flanges, including those that are FDA approved for use in food processing and beverage applications. John Crane stainless steel flanges are manufactured using high-quality stainless steel and designed to meet the most rigorous demands.

Flowserve

Flowserve is a leading provider of fluid motion and control products and services. The company’s products are used in a variety of industries, including oil and gas, power generation, mining, chemical processing, and pulp and paper. Flowserve is headquartered in Irving, Texas, and has more than 16,000 employees worldwide.

The company offers a wide range of products and services, including:

- stainless steel Vanstone flange

- valves

- pumps

- seals

- automation

- engineering services

Flowserve’s valves are used in a variety of applications, including pipelines, refineries, and process plants.

9. Types of Flanges and Their Applications

There are many different types of flanges, each with a unique set of applications. Some of the most common types are:

Slip-on Flanges

These flanges are easy to install and are ideal for low-pressure applications. It’s a good choice for small-diameter pipes because there are no welding or stainless steel flange bolts required.

Weldneck Flanges

These flanges have a long neck that is welded to the pipe, making them incredibly strong. They are ideal for high-pressure and high-temperature applications.

Socket Weld Flanges

These flanges are similar to weld neck flanges, but the neck is threaded instead of welded. They are also ideal for high-pressure and high-temperature applications.

Blind Flanges

These flanges cover the end of a pipe and are used to seal it off. It’s a good choice for high-pressure or high-temperature applications.

Lap Joint Flanges

These flanges are similar to slip-on flanges, but the mating surfaces are not parallel. This makes them ideal for high-pressure applications.

Threaded Flanges

These flanges have screw threads on the outer diameter that allow them to be screwed onto a pipe. It’s a good choice for low-pressure and low-temperature applications.

Orifice Flanges

These flanges are designed to attach flow meters onto a pipe. The middle of the flange is machined out and has an opening that matches up with the flow meter. It’s a good choice for high-pressure or high-temperature applications.

Reducing Flanges

These types of stainless steel slip-on have different sized openings at each end, allowing them to be connected to two different sized pipes. It’s a good choice for low-pressure and low-temperature applications.

If you have questions about stainless steel slip-on or need help finding a specific type of stainless steel flange, don’t hesitate to contact our stainless steel experts at Oflange. We carry a wide range of stainless steel flanges in many different sizes and styles to meet your needs.

10. Specifications of Stainless Steel Flanges

Flanges are used to provide a pressure-tight joint between two pipes or to connect a pipeline to equipment. Flanges come in a variety of sizes and shapes and are made of different materials including stainless steel.

The stainless steel flange specification must meet to ensure a high level of quality and corrosion resistance. The American Society of Mechanical Engineers (ASME) publishes standards for stainless steel flanges, which include the following:

Flange Type

There are several types of stainless steel flanges, including slip-on, weld neck, blind, and threaded.

Nominal Size

The nominal size is the diameter of the flange in inches. It is important to select the correct nominal size when ordering a stainless steel flange.

Pipe Schedule

The pipe schedule is the thickness of the stainless steel flange. It is expressed in terms of schedule numbers (e.g., Schedule 40, Schedule 80, etc.).

Class Rating

There are several class ratings for stainless steel flanges, including 150, 300, 600, and 900. This corresponds to a pressure range in pounds per square inch (PSI). For example, a stainless steel flange with a 150 class rating can withstand up to 150 PSI.

Temperature Class

The temperature class indicates the stainless steel flange’s maximum allowable service temperature in degrees Fahrenheit. For example, a stainless steel flange with A105N material can withstand up to 750°F (399°C).

If you need your stainless steel flange to be able to withstand higher temperatures, you can select a stainless steel flange with a higher temperature class.

Geometry

The geometry is specified by the ASME B16.48 standard. This includes the stainless steel flange dimensions (see the stainless steel flange dimensions chart pdf), as well as the tolerances.

When selecting a stainless steel flange, it’s important to make sure that the flange meets the requirements of your project. The ASME standards are a good starting point, but you may need to consult with a supplier or manufacturer to ensure that the stainless steel flange you select is compliant with your specific application.

11. Conclusion

Stainless steel flanges are a great choice for stainless steel pipe fittings as they are incredibly strong and hard-wearing. Their excellent corrosion resistance makes stainless steel flanges perfect for use in many different industries, including oil & gas, pharmaceuticals, food processing, and more.

If you’re looking for a stainless steel flange, be sure to get in touch with the team at Oflange. We have a wide range of stainless steel flanges available and we’d be happy to help you find the perfect fit for your needs.