PRODUCT FEATURES

SS316 Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

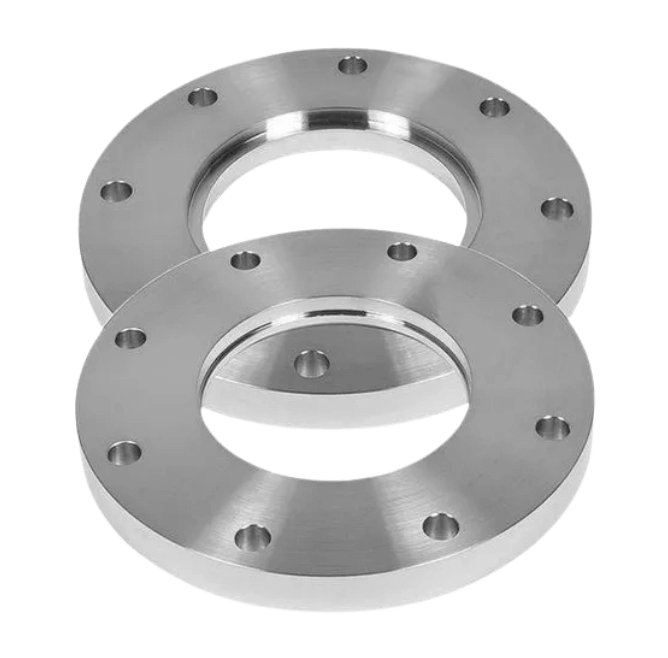

SS316 Flange

Do you need a corrosion-resistant flange for your next project? If so, you may want to consider using SS316.

This type of flange is made from 316 stainless steel, which is known for its resistance to corrosion and staining. In addition, SS316 flanges are strong and durable, making them ideal for a variety of applications.

In this blog post, we’ll discuss everything you need to know about SS316 flanges, including what they are used for and how to choose the right one for your needs. We’ll also provide a few recommendations for some of the best SS316 flanges on the market. So without further ado, let’s get started!

Table of contents

1. SS316 Flange Definition and Its Uses

A flange is a type of connector that screws onto a threaded pipe to provide a secure closure. SS316 flanges are made of the stainless steel grade 316, which is a chromium-nickel-molybdenum alloy with excellent corrosion resistance.

It is commonly used in chemical and food processing, pharmaceuticals, and breweries. 316 ss flanges have a wide range of applications in many industries. In the chemical industry, they are used to connect pipes carrying corrosive fluids.

In the food industry, they are often used to connect beer brewing equipment. They are also popular in the pharmaceutical industry, where they are often used to connect high-purity piping systems.

It can be used in applications where temperatures up to 1400 degrees Fahrenheit are required. The SS316 flange is also ideal for use in applications that require a high level of pressure. They are available in a variety of sizes and shapes, making them versatile enough for use in a wide range of applications.

2. SS316 Flange Composition

SS316 flange is composed of chromium, nickel, and molybdenum. They are made from stainless steel 316, which is a type of austenitic stainless steel. They are also immune to chloride-ion stress corrosion cracking.

When compared to other types of steel alloys, SS316 flange composition offers higher corrosion resistance. This is due to the alloy’s high percentage of chromiumandnickelcontent.

The chromium content helps to form a thin, stable oxide layer on the surface of the steel, which helps to protect it from corrosion. The nickel content contributes to the alloy’s overall strength and toughness.

SS316 din flanges are a popular choice for many applications because of their corrosion resistance and strength. They are available in a variety of sizes and configurations.

3. The Manufacturing Process of SS316 Flange

When it comes to manufacturing SS316 joint flanges, there are a few key steps that need to be followed to create a quality product. Here is a brief overview of the process:

Step#1 Inspection of Raw Material

Before any manufacturing can take place, the SS316 material needs to be inspected and approved. This is to ensure that only the highest quality materials are used in the flange production process.

Step#2 Blanking

The SS316 sheet is then cut into the desired shape or size using a blanking machine. This results in a circular disc that will become the flange.

Step#3 Piercing

The disc is then pierced using a piercing machine to create the bolt hole in the center of the flange.

Step#4 Forming

The pierced SS316 disc is then put into a forming machine, which shapes it into the desired flange design.

Step#5 Annealing

After the SS316 flange is formed, it is then annealed to remove any stresses that may have been introduced during the manufacturing process. This helps to ensure that the flange will be strong and durable.

Step#6 Grinding

The SS316 flange is then ground down to create a smooth and uniform surface.

Step#7 Polishing

The SS316 flange is then polished to a high shine. This not only makes it look great but also helps to protect it from corrosion.

Step#8 Inspection

After it has been polished, the SS316 flange is inspected one last time to ensure that it meets all quality standards.

Once the manufacturing process is complete, the SS316 flange is ready for shipment to its final destination.

SS flange specification is an important part of the manufacturing process for many products. There are a variety of different SS flange specifications, and each one is designed for a specific use. By following the steps outlined above, you can be sure that you are getting a product that will meet your needs and expectations.

4. The Different Class of SS316 Flange

SS316 flange is a type of stainless steel flange that is made of SS316 materials. There are different classes of SS316 flanges, and each class has its unique properties.

Here are some brief descriptions of the different flanged fittings classes of SS316 flanges:

Class 150 SS316 Flanges

Class 150 SS316 flanges are the most basic type of SS316 flange. They are made of SS316 materials and have a pressure rating of 150 pounds per square inch. They are typically used in low-pressure applications.

Class 300 SS316 Flanges

Class 300 SS316 flanges are made of SS316 materials and have a pressure rating of 300 pounds per square inch. They are typically used in medium-pressure applications.

Class 600 SS316 Flanges

Class 600 SS316 flanges are made of SS316 materials and have a pressure rating of 600 pounds per square inch. They are typically used in high-pressure applications.

Class 900 SS316 Flanges

Class 900 SS316 flanges are made of SS316 materials and have a pressure rating of 900 pounds per square inch. They are typically used in very high-pressure applications.

Class 1500 SS316 Flanges

Class 1500 SS316 flanges are made of SS316 materials and have a pressure rating of 1,500 pounds per square inch. They are typically used in ultrahigh-pressure applications.

Each class of SS316 flanges has unique properties that make it ideal for certain applications. Make sure to choose the right SS316 flange for your needs to ensure the best results.

5. Different Size of SS316 Flange

SS316 flanges are available in different sizes to meet the requirements of different applications. The size of an SS316 flange is specified by the large-diameter steel flanges of the flange opening and the thickness of the flange.

There are Different Size of SS316 Flange including:

- SS316 Flange, 1/4″ Thickness

- SS316 Flange, 1/2″ Thickness

- SS316 Flange, 3/4″ Thickness

- SS316 Flange, 1″ Thickness

- SS316 Flange, 1-1/4″ Thickness

- SS316 Flange, 1-1/2″ Thickness

- SS316 Flange, 1-3/4″ Thickness

- SS316 Flange, 2″ Thickness

- SS316 Flange, 2-1/2″ Thickness

- SS316 Flange, 3″ Thickness

- SS316 Flange, 3-1/2″ Thickness

- SS316 Flange, 4″ Thickness

- SS316 Flange, 5″ Thickness

- SS316 Flange, 6″ Thickness

- SS316 Flange, 8″ Thickness

- SS316 Flange, 10″ Thickness

- SS316 Flange, 12″ Thickness

- SS316 Flange, 14″ Thickness

- SS316 Flange, 16″ Thickness

- SS316 Flange, 18″ Thickness

- SS316 Flange, 20″ Thickness

- SS316 Flange, 24″ Thickness

When it comes to choosing the right flange, size is an important consideration. The stainless steel flanges dimensions can vary depending on the pipe size, thickness, and material.

There are many different sizes of SS316 flange available on the market. It is important to choose the right size for your needs. A flange 316 that is too small may not be effective, while an SS316 flange that is too large may be difficult to use.

6. Advantages and Disadvantages of SS316 Flange

When it comes to SS316 Flange, there are some advantages and disadvantages that should be considered. Here are some of the most important ones:

| Advantages | Disadvantages |

|---|---|

| SS316 flange is made of high-quality stainless steel, which makes it strong and durable. | SS316 flange can be more expensive than other types of flanges. |

| It is also resistant to corrosion and rust, making it a good choice for applications that require a high level of corrosion resistance. | It can also be more difficult to weld and fabricate, so it may not be the best choice for applications that require a lot of welding. |

| They have a high-temperature tolerance and can be used in applications up to 1000 degrees Fahrenheit | They are not as strong as other materials, such as steel, and can be susceptible to damage if not handled properly. |

| They are also non-magnetic, which makes them ideal for use in high-tech and sensitive industries |

When deciding if SS316 flanges are the right choice for your application, be sure to weigh all the pros and cons.

7. Applications of SS316 Flange in Various Industries

SS316 flanges are often used in various applications across several industries. Some of the most common applications include:

Chemical Processing

The high corrosion resistance of SS316 makes it ideal for use in harsh environments where chemicals are present. Additionally, the high strength and toughness of SS316 make it ideal for use in processes where high pressure is present.

Food and Beverage Production

Another common application for SS316 flanges is in food and beverage production. SS316 is ideal for use in food and beverage production because it is non-toxic and has high corrosion resistance. SS316 flanges are also resistant to heat, which makes them ideal for use in high-temperature environments.

Pharmaceuticals

Pharmaceuticals are a vital part of the healthcare industry. They are used to treat a variety of illnesses and conditions and play a vital role in the overall health of individuals.

SS316 flanges are often used in pharmaceutical applications because of their high corrosion resistance and toughness. Additionally, SS316 flanges are easy to clean and sanitize, making them ideal for use in pharmaceutical applications.

Power Generation

An SS316 plate flange is an important component of a high-pressure turbine. It helps to connect the turbine blades to the rotor. The high-pressure steam from the boiler flows through the turbine blades, causing them to rotate. This rotation powers the generator to produce electricity.

Each of these industries has different requirements when it comes to SS316 flanges, so it is important to work with a supplier who understands the specific needs of your industry.

8. SS316 Flange Average Cost

The SS316 Flange is a component that is used in many different industries. The component is made from a high-quality material that allows it to be used in a variety of settings. It is also a cost-effective option for many businesses.

The SS316 Flange is usually priced based on the size and the quantity that is ordered. The average cost of an SS316 Flange is between $8 and $12. This ss 316 flange price range can vary depending on the supplier and the manufacturing process.

They are a great choice for high-pressure and corrosive applications. They are also available in a variety of sizes to fit most pipe diameters. When selecting an SS316 Flange, be sure to consider the pressure and temperature requirements of your application. The threaded flange must be able to handle the stress that is placed on it.

9. Where to Purchase SS316 Flange in Bulk

When looking for an SS316 flange in bulk, it is important to find a supplier that can provide you with the quality product that you need. Here are some of the best places to purchase SS316 flange in bulk:

Online Suppliers

There are several online suppliers that sell SS316 flanges. This is a convenient option if you are looking for a variety of sizes and types of plate flanges. Be sure to compare prices and delivery times to find the best supplier for your needs.

Local Suppliers

If you are looking for a local supplier, try doing a Google search for SS316 flanges in your area. This will give you a list of suppliers near you.

Manufacturers

Some manufacturers also sell SS316 flanges. This can be a good option if you need a specific size or type of flange that is not commonly found online or through local suppliers.

One of the best manufacturers in China is Oflange. We supply SS316 flange, SS304 flange, SS316L flange, SS304L flange, and other 316 stainless steel flanges. With years of experience in manufacturing and exporting stainless steel 316 flanges products, we can assure you of the quality and consistency of our products.

If you are interested in purchasing SS316 flanges from us, please do not hesitate to contact us at Oflange.

Overall, there are a variety of places to purchase SS316 flanges in bulk. By considering the options above, you should be able to find the best supplier for your needs.

10. 3 Tips to Select the Right SS316 Flange for Your Needs

When selecting an SS316 flange, it’s important to consider the type of service it will be used for, as well as the operating conditions. Here are some tips to help you choose the right SS316 flange for your needs:

#1 Choose the Right Size

When selecting an SS316 flange, it’s important to choose the correct size. The flange should be large enough to cover the opening, but not so large that it becomes cumbersome or difficult to work with.

#2 Consider the Type of Service

When selecting an SS316 flange, it’s important to consider the type of service it will be used for. For example, if the SS316 flange will be used in an aggressive environment, you’ll need to select a model that can withstand the rigors of that environment.

#3 Consider the Operating Conditions

When selecting an SS316 flange, it’s important to consider the operating conditions. For example, if the SS316 flange will be used in a high-temperature environment, you’ll need to select a model that can withstand the heat.

When selecting a SS flange, it is important to consider the ss flanges specifications. By following these tips, you can ensure that you select the right SS316 flange for your needs.

If you want to know how flanges are produced, watch this video.

11. Conclusion

SS316 flanges are among the most versatile and widely used pipe fittings in the world. They offer a high level of corrosion resistance and can be used in a variety of applications.

If you need a quality SS316 flange, call us at Oflange. With years of experience in the industry, we can help you find the perfect flange for your needs.