PRODUCT FEATURES

Spacer Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

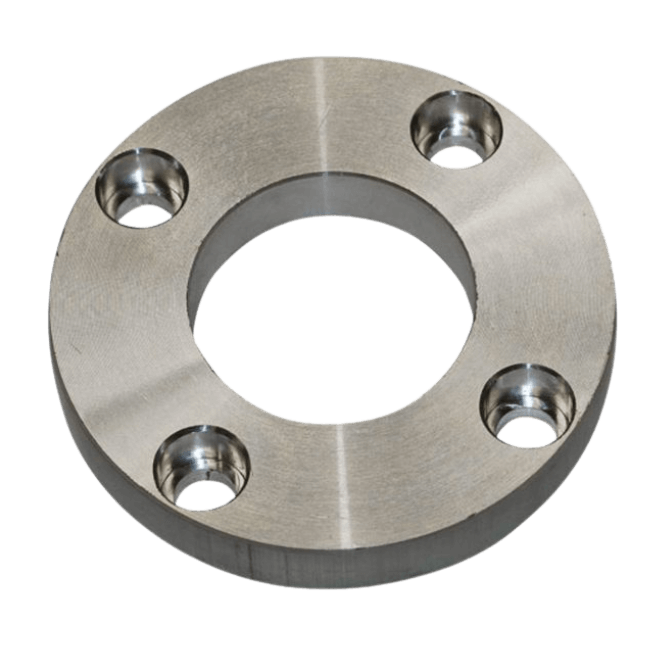

Spacer Flange

The Spacer Flange is a flange that is soldered to the inside of your pipe for use with a spacer. It comes in multiple sizes and can be used as either a male or female component. The flange has both an inner and outer diameter, which allows it to fit perfectly into any type of pipe.

This piece is extremely popular among plumbers and plumbing supply companies because it allows you to create custom flanges without having to buy expensive machinery. It also makes it easy for you to find the right size that you need.

The spacer flange is made out of brass, which makes it durable and resistant to corrosion. This handy little tool slips over your pipe and provides a simple, hassle-free way to create the space you need.

Table of contents

1. Spacer Flange Definition and How It Works

A spacer flange is a type of flange that is used to space two or more pieces of pipe or tubing. The spacer flange helps to keep the pipes or tubes in alignment, and also provides a surface on which to weld or bolt the other flanges.

The spacer flange is made from a durable single piece of metal that is cut to fit the pipe size, and it fits between two pipe flanges. It is either welded or bolted to the pipe or tubing. It requires an additional gasket when placed.

Spacer flange works by providing a gap between two flanges that connect pipes. This spacer is inserted into the space between the two flanges and prevents them from touching, preventing a water leak.

2. Spacer Flange Key Features

Here are the key features of spacer flange.

Corrosion-Resistant

Spacer flange is constructed of metal that resists corrosion. This pipe flange spacer allows the spacer to be used anywhere without worrying about deterioration due to weather conditions.

Core Construction

A spacer flange has a core construction made of high-quality metal for enhanced weight capacity and durability, so it can withstand years of repeated use.

Ventilation

Spacer flanges have ventilation slots to allow spacer piping and spacer spool piping to ventilate so the flow rate stays the same. The spacer spool and spacer pipe need to stay at a constant temperature for an accurate reading or flow test results.

Screw-In Features

Spacer flange has a screw-in design so it is easy to attach spacer piping and spacer spool piping. This spacer flange also has a straight hole on a top part of spacer spool and spacer piping so it can be attached to the spacer spool and spacer pipe.

Proper Spacing

A spacer flange allows for proper spacing between spool piping and spacer spool piping, as well as spindle line and spindle piping, so that flow testing keeps accurate results as expected.

3. Parts & Construction of Spacer Flange

Parts of the spacer flange are:

| Spacer Flange Discs | The spacer flange discs are two circular plates with a hole in the middle that fit over the spindle. |

| Spacer Flange Bolt | The spacer flange discs are two circular plates with a hole in the middle that fit over the spindle. |

| Spacer Flange Washer | The spacer flange washer goes between the spacer flange discs and the spindle. |

| Spacer Flange Nut | The spacer flange nut screws onto the other side of the spacer flange bolt to hold everything together. |

The spacer flange is held in place between the spindle and the bearing housing by the spacer flange bolt. The spacer flange restricts the lateral movement of the spindle, which keeps the bearings in place and ensures that the spindle turns at a constant speed.

4. The Difference Between a Spacer Flange and Other Types of Flange

When it comes to spacer flanges, there are a few key things that set them apart from other types of flanges.

Spacer Flanges Have a Hollow Center

First and foremost, spacer flanges have a hollow center that allows for the passage of fluid or other materials compared to spacer blind flange. This makes them ideal for use in pipelines and other systems where flow is important.

Spacer Flanges are Thinner

Second, flanged spacer is typically much thinner than other types of flanges, which makes them easier to install and less likely to cause interference issues.

Spacer Flanges Can Be Combined With Other Flange

Finally, spacer flanges are often used in combination with other types of flanges, such as weld neck or slip-on flanges. This allows for more flexibility when designing and assembling pipelines and other systems.

5. Spacer Flange Dimensions

The spacer flange dimensions can be specified in two ways: by the outside diameter of the spacer flange or by the bolt circle diameter. The spacer flange dimensions should also include the thickness of the spacer flange.

Here are the dimensions of spacer flange:

- Outside diameter is 2-1/2″

- Bolt holes circle diameter is 2-1/4″

- Thickness is 1/4″

Spacer flange dimensions are essential for the correct installation of spacer flanges. The spacer flange dimensions must be matched to those of the mating flange. If the spacer flange dimensions are not matched correctly, the spacer flange may not seal properly, which could lead to leakage.

6. Step by Step Guide on Flange Spacer Installation

Here is a step by step guide on flange spacer installation.

Step #1 Locate the Spacer Flange

This is the first step on how to install flange spacer, locate the flange. The spacer flange is a round, flat disk that helps to position and secure the flanges of two pipes.

It is usually made from a strong, corrosion-resistant material like stainless steel. The spacer flange is located between the pipe flanges, and helps to keep them evenly spaced apart.

Step #2 Insert the Spacer Flange

Once you have located the spacer flange, insert it between the pipe flanges. Make sure that the spacer flange is inserted evenly between the two flanges.

Step #3 Secure the Spacer Flange

Once the spacer flange is in place, use the bolts or clamps to secure it in place. Be sure to tighten the bolts or clamps securely, so that the spacer flange does not move.

Step #4 Check the Spacer Flange Alignment

Once the spacer flange is in place, check to make sure that it is aligned properly. If it is not aligned correctly, the spacer flange may not work properly and could cause leakage.

Step #5 Test the Seals

Once the spacer flange is in place, test the applied seals to make sure that they are working properly. If there is any leakage, tighten the bolts or clamps until the leakage stops.

If you are using a spacer flange to attach two flanges, be sure to use a spacer flange that is the same measure size as the flanges. Also, be sure to use a spacer flange that is made from a strong, corrosion-resistant material.

If you are not sure which spacer flange to use, consult with an approved professional engineer.

7. Benefits of Using Spacer Flange

Here are some benefits of using spacer flange.

Easy to Install

Spacers are available in different sizes, shapes, and materials. Mounting is not difficult because it can be easily installed on walls or ceilings. They are light weight making installation easy.

Spacing is required when you have pipes of different diameters. It creates the necessary gap that is needed to ensure free movement of pipes.

Durable

The spacer flange is durable because it has a thick metal plate that can withstand impact and pressure in piping system. These spacer flanges are made from high-quality materials so they will last long without any signs of wear and tear.

The steel pipe flange spacers is not easily damaged due to the materials being used for production, so you are assured of its durability even with long-term use.

Watertight Seal

Every spacer flange is designed with a special device that makes it watertight. When this spacer plate is securely fastened, the system will remain dry and watertight. Even if spacer flange has a stud bolt, it is still configured to remain watertight because of the gasket between its spacer plate and pipe.

Easy to Clean

Because spacer flanges are made from durable materials, they are easy to clean. You do not need special chemicals or cleaning equipment. If there are spacer flanges with gaskets, you only need a damp cloth to wipe spacer flange clean.

Affordable

Spacers are very affordable so there is no need for you to buy expensive spacer plates in the market. You can have spacer flange at a lower cost with its quality unmatched by spacer plates with fancy designs.

8. Where to Find Wholesale Spacer Flange

There are a few different ways to find a supplier of spacer flange. You can purchase this product from:

- Online retail stores

- Hardware stores

- Local steel supplier

- Larger industrial manufacturing companies such as Oflange

Some suppliers offer other services like spacer flange fabrication and spacer flange installation. You must find a supplier who can offer the spacer flange in different sizes and materials to meet your specific needs.

9. Average Cost of Spacer Flange

The price of a spacer flange may vary depending on the size and type of spacer flange you purchase. Generally, the average spacer flange cost is USD 18 per kg.

A spacer flange with an average weight of approximately two pounds will usually carry a price tag at wholesale spacer flange supplier of USD 36, including shipping costs.

With the possibility of ordering spacer flang in bulk quantities of up to 2,000 spacer flange pieces, spacer flange prices become even more affordable.

10. 5 Tips for Spacer Flange Maintenance

Here are some tips to maintain your spacer flange.

#1 Always Inspect Spacer Flange For Damage

It is important to always inspect spacer flange for damage before each use. Damaged spacer flange can lead to leakage and other problems.

#2 Inspect Gaskets and Seals

Inspect the gaskets and seals around spacer flange fittings regularly. If they are damaged, replace them immediately.

#3 Keep Spacer Flange Clean

Spacer flange should be kept clean to avoid corrosion and other problems. Use a mild detergent and water to clean spacer flange, then dry thoroughly.

#4 Lubricate Fittings

If spacer flange fittings are tight, lubricate them with a light coating of oil or silicone spray. This will help prevent damage to the flange spacers and the fittings.

#5 Store Spacer Flange Properly

When not in use, store spacer flange in a dry place where it will not be damaged. Do not store spacer flange near heat or flame.

Follow these tips to ensure long-lasting spacer flange performance.

11. Conclusion

Spacer flanges are essential tools in many industries. They have key features that make them corrosion-resistant, durable, and able to withstand repeated use.

To get the most out of your spacer flange, it is important to maintain it properly. If all of the details check out on your list, then this is the sign that a spacer flange is a perfect option and we agree.

If you have any questions or need additional information, please do not hesitate to contact us at our website Oflange. We would be happy to help!