PRODUCT FEATURES

SA 105 Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

SA 105 Flange: All You Need to Know

If you’re in the business world, then you know that there are a seemingly endless number of terms and lingo that can be confusing. One such term is “SA105 flange.” What is an SA105 flange?

We’ll discuss the different types of SA 105 flanges available and explain the key features and benefits of each. Plus, we’ll provide some tips on how to select the right flange for your application.

In this blog post, we’ll take a closer look at what makes SA 105 flanges so special, and we’ll provide some tips on how to choose the right one for your needs. So if you’re ready to learn more about this popular flange type, keep reading!

Table of contents

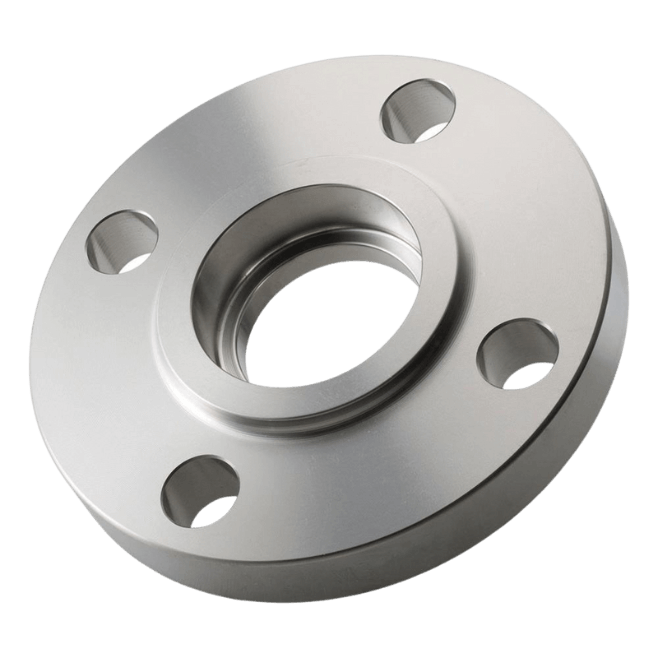

1. What Is a SA 105 Flange

A SA 105 flange is a type of pipe flange that is used to connect two pipes. It has a hole in the middle that allows you to bolt the two pipes together. This type of flange is often used in industrial applications, and it comes in a variety of different sizes and shapes.

A SA 105 flange is a type of flange that is commonly used in the piping industry. It is made from carbon steel and has a nominal size of 105 mm. The same 105 flanges are often used in conjunction with other flanges, such as the SA 150 flange. This type of flange is often used in the construction of oil and gas pipelines.

A SA 105 flange is a simple and economical way to join pipes together. The SA 105 flanges are made of malleable iron and have a threaded connection. It can be used with either steel or copper pipe.

2. Applications of SA 105 Flange

SA 105 flanges are commonly used in industrial applications. Some of the most common applications include:

Petroleum Refineries

A SA 105 flange is a type of flange that is used in the petroleum refining industry. It is a type of forged steel flange that is commonly used in high-pressure applications. The SA 105 flange is designed to be used in high-pressure piping systems, and it is capable of withstanding high levels of stress and pressure.

The SA 105 flange is a popular choice for use in the petroleum refining industry because it is strong and durable. It can withstand high levels of stress and pressure without fail, making it an ideal choice for use in critical applications.

Additionally, the SA 105 flange is relatively easy to install and can be quickly put into place without causing any delays or problems.

Chemical Processing

Chemical processing plants are an important part of the manufacturing process for a wide range of products that we use every day. The plants require a variety of different flanges to connect different parts of the plant, and the SA 105 flange is one of the most commonly used flanges in these applications.

The SA 105 flange is designed for use in high-pressure applications and is made from stainless steel for maximum strength and corrosion resistance. It is also available in a wide range of sizes to meet the needs of any chemical processing plant.

Paper Mills Plants

SA 105 flange is an essential piece of equipment in any paper mills plant. It is used to connect the mill’s piping system and allow the flow of fluid between different parts of the plant. A SA 105 flange must be made from high-quality materials to ensure durability and reliability. It must also be properly sealed to prevent leaks.

Paper mills plants rely on a SA 105 flange to function efficiently. The flange helps to move the pulp and water through the plant, which is essential for producing paper. Without a SA 105 flange, the plant would not be able to operate properly.

Power Generation Facilities

The SA 105 flange is a type of flange that is used in the power generation industry. It is a forged steel flange that is designed for use in high-pressure applications. The SA 105 flange is also designed to be used in high-temperature applications.

3. How Is a SA 105 Flange Installed

The installation process for a SA 105 flange varies depending on the type of flange and the type of pipe that it is being installed on. However, in most cases, the flange will be bolted to the pipe using a series of bolts and nuts.

Step #1 Put the Flange on the Pipe

Put the flange on the pipe. This should be a tight fit. If it is not a tight fit, use a pipe wrench to tighten it.

Step #2 Put the Gasket on the Flange

Put the gasket on the flange. This should also be a tight fit. If it is not a tight fit, use a pipe wrench to tighten it.

Step #3 Apply Joint Compound

Apply pipe joint compound to the threads of the pipe.

Step #4 Screw the Pipe Into the Flange

Screw the pipe into the flange. Use a pipe wrench to tighten it as much as possible. Do not over-tighten it, or you may damage the flange or the pipe.

There you have it! You have now installed a SA 105 flange. Remember to use pipe joint compound on the threads of the pipe, and to tighten the flange as much as possible without over-tightening it. Contact us at Oflange for more information!

To know more about how flanges are installed, watch this video.

4. Common Problems With SA 105 Flanges and How Can They Be Avoided

SA 105 flanges can experience several different problems during operation. Some of the most common problems include:

Leaks

Leaks can occur with SA 105 flanges for several reasons. One common problem is improper installation, which can cause the gasket to fail.

Another issue that can lead to leaks is when the flange is not properly aligned with the mating surface. This can cause the bolts to be over-tightened, which can damage the flange and lead to leaks.

First, always make sure that the flanges are properly aligned and seated before bolting them together. Improper alignment can lead to leaks and other problems.

Corrosion

When it comes to corrosion, SA 105 flanges are particularly susceptible. There are a few ways to avoid this, however. One is to use a coating that will protect the flange from the elements. Another is to use a higher grade of steel that is more resistant to corrosion.

Finally, proper installation and maintenance are key in preventing corrosion on SA 105 flanges.

Damage to the Flange Face

Damage to the flange face is a common problem with SA 105 flanges. This can be caused by several factors, such as incorrect installation, over-tightening of bolts, or using the wrong type of bolts.

Damage to the flange face can also be caused by corrosion. Take care not to damage the flange face and carbon steel pipe when installing or removing bolts.

Warping or Distortion of the Flange

Warping or distortion of the flange is a common problem with SA 105 flanges. This can be caused by several factors, such as incorrect installation, excessive stress, or high temperatures. If this occurs, the flange may not seal properly and could lead to leakage.

There are several ways to avoid this problem. One is to ensure that the SA 105 flange is installed correctly. This includes making sure that the flange is aligned in the bolt hole properly and that the bolts are tightened evenly. Additionally, it is important to ensure that the flange is not subjected to excessive stress or heat.

By following these simple tips, you can help ensure that your SA 105 flanges experience minimal problems and provide many years of reliable service.

5. SA 105 Flange Price List

Here’s a list of prices for the SA105 Flange. Prices are subject to change without notice.

SA 105 Flange Description: A carbon steel flange that is designed for use with pipe fittings.

Size: 1/2″ to 24″

Approx. Wt/Unit: 2.68 kg to 166.72 kg

SA 105 Flange Price: $3.00 to $275.00

Gasket Price: $15

Pipe Joint Compound Price: $25

Bolt Kit (12 bolts and nuts) Price: $50

Material: Carbon steel

Finish: Black or galvanized

Contact us today for a free quote! Oflange is the leading provider of SA 105 flanges and other pipe fittings. We offer competitive pricing and quick delivery. Contact us today to learn more!

6. SA 105 Flange Specification

There are several different specifications that you should consider when selecting a SA 105 flange. Here is the list of the ASTM A105 flange specification.

| Size | Diameter of 3 inches |

| Type | Most common type is the slip-on flange |

| Material | Made of carbon steel |

| Pressure Rating | Maximum allowable pressure |

Size

The smallest flange SA 105 has a diameter of 3 inches, and it is perfect for use in small-diameter pipes. It is also lightweight and easy to install, which makes it ideal for use in tight spaces. However, its small size also makes it less durable than larger flange and bolts bolt size diameter.

Type

There are various types of ASTM a105 flanges available on the market. The most common type is the slip-on flange, which is typically made from steel and has a slip-on collar that allows it to be attached to a pipe without welding.

Material

The SA 105 flanges are made of carbon steel. It has a pressure rating of 400 psi. It is available in sizes from 2″ to 24″. The SA 105 flange is ideal for use in low-pressure applications. It has a weld neck design that makes it easy to weld to the pipe. The SA 105 flange is available in both standard carbon steel a105 and metric sizes.

Pressure Rating

One of the most important aspects of a flange is the pressure rating. The pressure rating determines the maximum allowable pressure that the flange can withstand. It’s important to ensure that the pressure rating of the flange is greater than or equal to the maximum allowable pressure of the piping system.

7. Types of SA 105 Flange

There are a variety of different types of SA 105 flanges available, each with its own unique set of features and benefits. The most common types include:

Weld Neck Flange

Weld neck flanges are a type of flange that is commonly used in high-pressure and high-temperature applications. They are typically made from forged steel and are very strong and durable. Weld neck flanges are also very resistant to corrosion, which makes them a popular choice for many applications.

Threaded Flange

A threaded flange is a type of flange that features screw-like protrusions on the circumference of its bore. This type of flange is used to join two pipes or tubes together, and the screws help to create a tight seal between the two surfaces.

Threaded flanges are available in a variety of sizes, and they can be made from a variety of materials, including steel, aluminum, and brass.

Lap Joint Flange

Lap Joint Flange is a type of flange that is used to connect two pipes. It is a forged fitting that is made out of steel and it has a lap joint. The lap joint flange is used to join two pipes together and it is also used to make a connection between a pipe and a fitting.

The lap joint flange is also called a slip-on flange and it is the most common type of flange that is used in the United States.

Socket Weld Flange

A Socket Weld Flange is a type of flange that is welded to a pipe. It is a common type of flange that is used in many industries. Socket Weld Flanges are made from a variety of materials, including stainless steel, ASTM a105 carbon steel flanges, and alloy steel.

8. SA 105 Flange Standard

The SA 105 flange standard is commonly used in the piping industry. It covers the dimensions, shape, and tolerances of flanges and gaskets for use in high-pressure and high-temperature systems. The standard is also applicable to low-pressure and low-temperature systems.

The SA 105 flange standard is based on the ISO 6708 standard. It specifies the dimensions and shape of flanges and gaskets, as well as the tolerances that are allowed. The standard also includes requirements for testing and inspection.

There is no single standard that governs the design and manufacture of SA 105 flanges. However, most SA 105 flanges are manufactured to meet or exceed the requirements of ASME B16.36.

9. Dimensions of SA 105 Flange

The dimensions of a SA 105 flange are based on the SA 105 flange standard. The standard covers the dimensions, shape, and tolerances of flanges and gaskets. It also specifies the requirements for testing and inspection.

Most SA 105 flanges are manufactured to meet or exceed the requirements of ASME B16.36. The ASME B16.36 standard covers the dimensions, shape, and tolerances of SA 105 flanges. It also includes requirements for testing and inspection.

The dimensions of a SA 105 flange are based on the following:

- Bore diameter

- Bolt circle diameter

- Number of bolts

- The thickness of the gasket

- The thickness of the flange

- Hub length

- Overall length

- Width of the flange

- The height of the flange

The dimensions of SA 105 flanges vary depending on the size and type of flange. The most common sizes are:

- 15 inches (381 mm)

- 18 inches (457 mm)

- 24 inches (610 mm)

- 30 inches (762 mm)

- 36 inches (915 mm)

10. SA 105 Flange Material Properties

When choosing a SA 105 flange, it is important to consider the material properties and how they will impact the overall performance of the system. Some of the key properties to consider include:

Strength

The strength of the SA 105 flanges can vary depending on the grade of steel used. Higher grades of steel and carbon steel blind flanges will typically have higher strength ratings, allowing them to withstand greater loads and pressures.

Corrosion Resistance

The SA 105 flange is resistant to corrosion, making it a good choice for applications where exposure to moisture or other corrosive elements is likely.

Wear Resistance

The SA 105 flange also has high wear resistance, making it ideal for applications where abrasion is common.

11. Conclusion

If you need an A105 flange for your business, please do not hesitate to contact us at Oflange. We would be more than happy to provide you with the best product possible.

Our team has years of experience and is more than capable of meeting your needs. Additionally, we offer competitive prices and quick turnaround times. Thank you for considering our company as your go-to source for all things related to A105 flanges.