PRODUCT FEATURES

Reducing Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

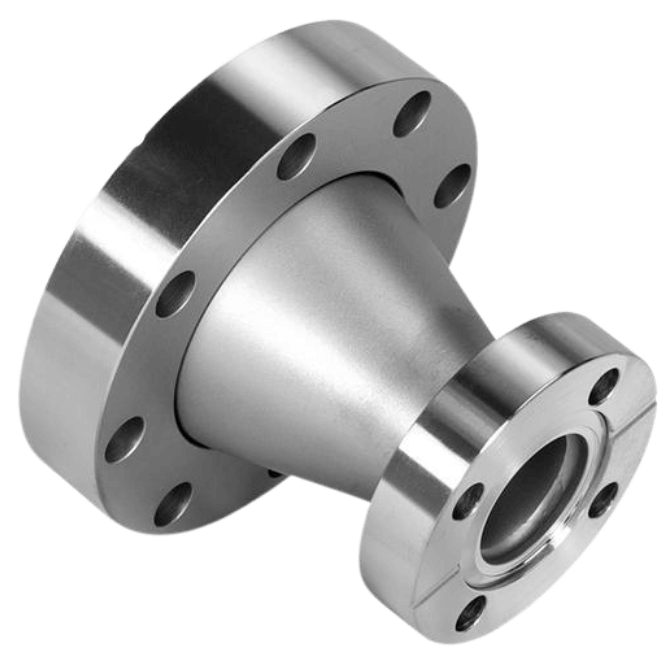

Reducing Flange

Reducing Flange is a unique device that helps to seal the flange of a pipe or fitting. This is an essential step in preventing leaks and ensuring a watertight seal. The flange can be difficult to tighten properly, but Reducing Flange makes the job much easier.

It features a ratchet mechanism that allows you to apply even pressure, making it possible to achieve a tight seal without any fuss. Reducing Flange is a simple, effective way to reduce the size of your flange opening without having to use a welding torch or other expensive equipment.

Table of contents

1. Reducing Flange Definition and Its Purpose

A reducing flange is a type of flange that is used to connect two pipes of different diameters. Reducing flanges are available in a variety of sizes, for instance, the 4×3 reducing flange has an inside diameter to weld to an 3 pipe with bolt hole mounting pattern to fit an 4 pipe flange, so it is important to choose the correct size for your application. Reducing flanges can either be raised or flat, depending on the shape of your application.

Reducing flanges are used in a variety of applications and industries and they provide many benefits when connecting pipes to ensure that there is a secure fit and that all connections are leak-proof.

The purpose of a reducing flange is to provide a gradual transition from one pipe size to another. This flange type is most commonly used in applications where the piping system must be able to withstand high pressures.

Reducing flanges are also commonly used in plumbing systems to connect the main water line to the smaller lines that run to individual fixtures. Reducing flanges typically have large bolts that are tightened to ensure a strong seal.

Reducing flange NPT Threads are designed to handle high pressure so reducing flanges are mainly used in plumbing systems. Reducing flange is also an important part of reducing cost.

2. Reducing Flange Key Features

Reducing flanges are a type of flange that is used to connect two different sized flanges. The smaller pipe is inserted into the larger pipe, and the reducing flange is then screwed onto the two pipes to hold them together.

Here are some of the key features of this type of flange:

They Are Easy To Use

Reducing flanges are very easy to use – all you need to do is insert the smaller pipe into the larger pipe, and then screw on the reducing slip on flange. This makes them a popular choice for connecting pipes in difficult-to-reach places.

They Have a High Strength to Weight Ratio

Reducing flanges also have a high strength-to-weight ratio. This means that they can withstand a lot of pressure without becoming damaged or deformed. As a result, they are ideal for use in high-stress environments.

They Have a Large Diameter

Reducing flange sizes range from four inches to sixteen inches, so this type of flange provides a lot of flexibility. Whether you need to connect pipes with different diameters or simply want more room for your fittings, reducing flanges is an ideal choice.

They also provide additional leverage when tightening the bolts which ensures that your vessel is secure.

They Are Versatile

Reducing flanges are also very versatile. You can use them to connect pipes of up to 3 inches in diameter, and they can be used for both high-pressure applications and low-pressure applications.

Overall, reducing flanges are a popular choice for use in a variety of applications. They allow you to connect pipes of different sizes with ease, and they have a high level of durability that makes them ideal for use in high-stress environments.

3. Parts & Construction of Reducing Flange

Reducing flanges are fittings that are used to connect two pipes of differing sizes. They are most commonly used to connect a pipe of a smaller diameter to a pipe of a larger diameter. Reducing flanges are made up of three parts:

The Body of Reducing Flange

The body of the reducing flange is the largest part of the fitting. Reducing flange threaded bodies are used to connect a reducing flange to a larger pipe. The threads on reducing flange bodies can be either raised or flat depending on the reducing flange model.

The body of the reducing flange is made from a variety of materials, including brass, stainless steel, and carbon steel. It is important to choose a material that is compatible with the type of pipe that will be connected to it.

The Gasket of Reducing Flange

The gasket of a reducing flange is an important part of the fitting. It is a rubber or elastomeric seal that sits between the two mating surfaces of the flange and helps to prevent leakage. The gasket is usually made from neoprene, viton, or EPDM rubber.

The gasket is placed between the body of the flange and the bolts and is compressed when the bolts are tightened. This creates a seal that prevents fluid from passing through.

The Bolts of Reducing Flange

Bolts are used to fasten the flanges together and hold them securely in place. Reducing flanges usually requires four bolts, though some can have six or eight bolts instead. Reducing flange bolts should always be tightened using a torque wrench so that they do not warp from over-tightening and damage the flange.

Reducing flanges used on cast iron piping often havehex key, which can be torqued with a wrench or ratchet. Reducing flange bolts that are made of ductile iron usually come with a square head, which can only be tightened using a socket.

It is important to know the parts and construction of a Reducing Flange before installing it. Reducing flanges are not very complicated, but all parts must be tightened securely to prevent leaks and ensure the safe transport of fluid through the pipes.

If you want to know more about the different types of flange, check out this video.

4. Reducing Flange Average Size and Dimension

When it comes to the average size and dimension of a reducing flange, there are many things to take into account. In addition to the size of the pipe and the thickness of the flange, you also need to consider the type of material that the flange is made out of.

For example, if you’re using a stainless steel pipe with a stainless steel reducing flange, you’ll need to make sure that the reducing flange dimensions of both the pipe and the flange are compatible.

The Reducing Flange has an average size of 1.5 inches and a bore and hub dimensions of 0.5 inches. Reducing Flanges are used to make a transition from a standard size flange to another reducing flange standard size. Reducing Flanges have the same outside dimension as their corresponding flange and differ in depth by 1/4 inch.

5. Step by Step Guide to Use Reducing Flange

A reducing flange is a type of pipe fitting that allows you to connect two pipes of different sizes. Reducing flanges can be used to connect a pipe with a smaller diameter to a pipe with a larger diameter, or to connect two pipes of the same size with each other.

Here are the step-by-step instructions on how to use a Reducing Flange:

| 1 | Cleaning |

| 2 | Installing Reducing Flange |

| 3 | Marking Pipe Location |

| 4 | Installing Pipe |

| 5 | Tightening Screws |

| 6 | Cleaning Pipe Threads |

| 7 | Check for Leaks |

Step#1 Cleaning

Make sure to clean the reducing threaded flange before using it. It will make the connection much easier and reduce leakage risks.

Step#2 Installing Reducing Flange

To install the reducing flange, first, position it in the desired location. Make sure that the pipe threads are facing the correct direction before tightening the screws. Use apipe wrench to tighten the screws until the flange is fully seated.

Step#3 Marking Pipe Location

Once the reducing flange is in place, use a marker or tape to mark the location of the pipe on the reducing flange. This will help you to align the pipe correctly when you install it.

Step#4 Installing Pipe

Before you install the pipe, make sure to insert a reducing bushing in between the reducing flange halves. This is required when connecting two pipes of different diameters. Once the reducing bushing is in place, insert the pipe until it’s fully seated against the top of the reducing flange.

Step#5 Tightening Screws

Use a pipe wrench to tighten the reducing flange screws. Be careful not to over-tighten them or you will damage both the reducing flange and the pipe it’s attached to.

Step#6 Cleaning Pipe Threads

After you’ve tightened the reducing flange screws, it’s a good idea to clean any excess sealant from the pipe threads. If there is too much sealant on the threads, it will prevent proper water flow and cause leaking.

Step#7 Check for Leaks

After your reducing flange is installed, turn on the water and check for leaks around both of the reducing flange connection points. Tighten any connections that need to be tightened before turning off the water.

After this step is complete, your reducing flange installation is done and ready for use! Now that you know how to use a reducing flange, you can connect virtually any two sizes of pipes with ease.

By following the steps above, you will have no problem using or installing a Reducing Flange. Keep the above tips in mind, and you will be able to use a Reducing Flange correctly.

6. Benefits of Using Reducing Flange

This reducing flange is very advantageous, but some people do not know that reducing flange are very beneficial for them.

Here are some benefits reducing flange can give:

Increased Efficiency

When you use reducing flange, it can help increase the efficiency of your piping system. This is because it will help reduce the resistance to flow and minimize turbulence. This will make the entire system run more smoothly and efficiently.

Enhanced Safety

Using slip-on reducing flange can also help to improve the safety of your piping system. This is because it will help reduce the chances of pipe failure due to stress and pressure. It can also help minimize the chances of leaks and pipe rupture. This will help keep your system safe and secure.

Durability

One of the main benefits of reducing weld neck flange is that it is extremely durable. This means that it can withstand high levels of stress and pressure without breaking or cracking. This makes it a very reliable option for your piping needs.

Minimal Vibration

Another benefit of reducing flange is that it can help minimize vibration. This is because it will help eliminate any unnecessary movement within the system. This will help keep the system stable and reduce the amount of noise it produces.

Ease of Installation

One of the benefits of reducing flange is that it is extremely easy to install. This means that it can be installed quickly and easily without any problems. This makes it a very convenient option for your piping needs.

By reducing flange, you can get a lot of benefits that you cannot get from using other types of piping systems. This reducing flange is one of the best-reducing flanges in many countries because it has a lot of beneficial features to offer.

7. Where to Find Wholesale Reducing Flange Manufacturers

When looking for a reducing flange manufacturer, it is important to find one that can provide a high-quality product. Some good places to find a wholesale reducing flange manufacturer are:

The Internet

The Internet is a great resource for finding a reducing flange manufacturer. A quick search will yield several results, and most manufacturers have websites where you can learn more about their products and services.

Trade Shows

Trade shows are another great place to find a reducing flange manufacturer. Manufacturers often exhibit at trade shows, so this is a great opportunity to see their products in person and learn more about their capabilities.

Industrial Suppliers

Another great place to find a reducing flange manufacturer is an industrial supplier. Industrial suppliers carry a wide variety of products, including reducing flange and can provide a lot of information about different manufacturers. They can also help you find the right reducing flange for your application.

There are a lot of reducing flange manufacturers out there and finding the right one can be difficult. When looking for a reducing flange, it is important to find one that can meet your material needs and provide you with a high-quality product. Using some of the tips above will help make the process easier.

8. Average Cost of Reducing Flange

When it comes to reducing flange, the average cost is something that should be considered. This is especially true when it comes to reducing the size of the flange. There are a few different ways that this can be done and each method has its own cost associated with it.

When reducing a flange, the average cost will depend on the type of flange that is being reduced, the size of the flange, and the availability of the necessary equipment. In general, the cost will be between $50 and $200 per flange.

The reducing flange, also known as a reducing nipple or reducing bushing, is a component of a fire sprinkler system. It is used to connect the water supply tubing to smaller pipe sizes.

The reduction flange can be circular weld neck flanges or square reducing flanges. Most reducing flanges have different sizes that are based on the number of reducing flanges.

9. 5 Tips for Reducing Flange Maintenance

There are a few things that you can do to help reduce flange maintenance. Some of these tips include:

#1 Keep the Flange Area Clean

One of the easiest ways to reduce flange maintenance is to keep the area around it clean. Make sure that there is no debris or dirt buildup in the surrounding area, as this can cause problems with the seal and increase wear and tear on the flange itself.

#2 Inspect the Flange Regularly

It is also important to inspect the flange regularly, especially if it is being used frequently. Make sure to check for any signs of wear or damage, and fix any issues as soon as possible. This will help to prevent further damage and reduce the need for future maintenance.

#3 Make Sure the Bolts and Nuts Are Properly Tightened

Another important thing to keep in mind when reducing flange maintenance is to make sure that the bolts and nuts are properly tightened. This will help to ensure a good seal and reduce the risk of leaks.

#4 Lubricate the Bolt Threads

One way to reduce flange maintenance is to lubricate the bolt threads. This will help to keep them in good condition and make it easier to loosen and tighten them when necessary. A good quality lubricant can help to preventcorrosionand wear and tear on the bolts, which can prolong their life span.

#5 Replace or Repair the Flange Whenever It Is Needed

Flanges eventually wear out and need to be replaced or repaired. If you want to reduce the amount of maintenance that is needed, make sure to replace or repair the flange as soon as possible whenever any issues arise. This will help to prevent further damage and keep the flange in good condition.

10. Conclusion

Reducing Flange is a unique device that makes it easy to achieve a watertight seal. It features a ratchet mechanism that allows you to apply even pressure, making it possible to tighten the flange without any fuss.

You won’t need a welding torch or other expensive equipment to reduce the size of your flange opening. Reducing Flange is simple and effective, and it will help you get the job done quickly and easily.

Purchase Reducing Flange today on our website!