PRODUCT FEATURES

PN16 Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

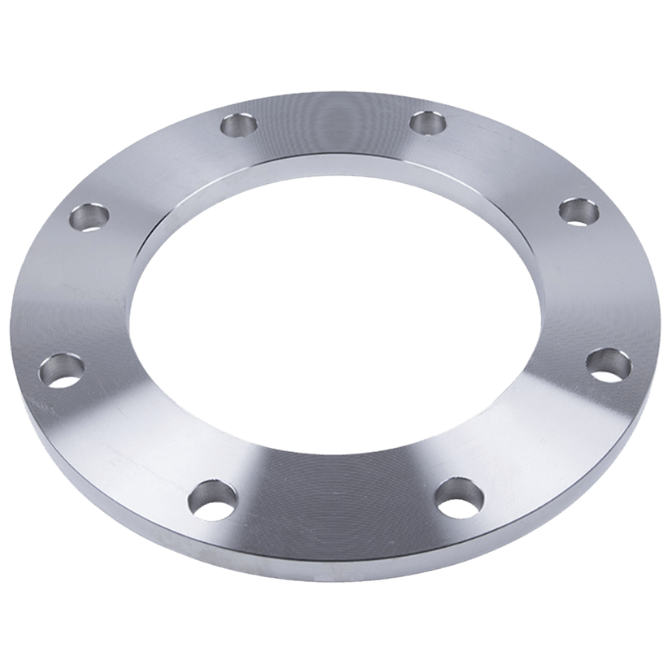

PN16 Flange

PN16 Flange is a great way to join two pieces of metal together. It’s simple to use and makes a strong joint. The PN16 Flange is a simple, yet effective tool that allows users to quickly and easily attach a variety of accessories to the rail system.

The PN16 Flange comes with four steel screws and is compatible with any Weaver/Picatinny rail system. PN16 Flange is perfect for connecting metal or plastic parts in DIY projects, repairs, and manufacturing.

Table of contents

1. PN16 Flange Definition

A PN16 Flange is a type of flange that is used in piping and valve systems. It is a type of flange that has a nominal pressure rating of 16 bar. It is specifically designed for use in systems where the media being conveyed has a pressure of up to 16 bar.

PN16 flanges are typically used in industrial and commercial applications. PN16 flange is similar to PN10, PN6, and PN25 flange. PN10, PN6, and PN25 are also pressure-rated flanges that have a nominal pressure rating of 10 bar, 6 bar, and 25 bar respectively.

The PN16 Flange is a common type of flange that is used in many applications. It is manufactured fromcorrosion-resistant materials. This type of flange has a dimension that is sized to meet the requirements of most piping and valve systems.

The PN16 Flange is also made using a manufacturing process that results in a high-quality product. It is also commonly installed on stainless steel, alloy steel, and other types of metallic piping systems.

2. Different Types of PN16 Flange

There are several different types of PN16 flanges available, each with its unique features and benefits. Here are a few PN16 flange types you should be aware of:

PN16/3 Slip-on Flange

This type of PN16 flange is designed for use with pipe fittings. It features a slip-on design that makes it easy to install and remove. It also has a tapered neck for a tight fit.

PN16/8 Blind Flange

This type of PN16 flange is used to seal off pipe ends or to cover steel flanges. It has a blind design that doesn’t have any connection to the pipe. This makes it ideal for use in high-pressure or hazardous environments.

PN16/4 BSPP Threaded Flange

The PN16/4 BSPP threaded flange is a type of PN16 flange that is designed for use with BSPP fittings. It features a threaded design that allows it to be easily attached to other components. This flange is also made from sturdy materials that can withstand high-pressure applications.

PN16/2 Weld Neck Flange

The PN16/2 weld neck flange is a type of PN16 flange that is designed for use in high-pressure applications. It is made from sturdy materials that can withstand high pressure and stress. This flange also features a weld neck design that allows it to be securely attached to other components.

Therefore, PN16 flanges are an excellent choice for your plumbing needs. Whether you need PN16 flanges or any other type of PN flange, you should be able to easily find the product that is right for your application.

3. The Difference Between PN16 Flange and Other Flange Types

Flanges are fittings that are used to connect pipes and tubes. There are many different types of flanges, but the most commonly used are PN16 flanges. PN16 flanges are the standard type of flange used in most industrial applications.

There are several differences between PN16 flanges and other types of flanges including:

Size

One of the biggest differences between PN16 flanges and other types is in their size. PN16 flanges can, as stated above, be used for piping up to 160mm in diameter, while most other types of the flange are limited to a maximum size of 125mm.

Face Type

The PN16 Flange has a flat face, but others types of the flange can have raised faces. Raised-faced flanges are helpful when bolting on the equipment that will be used with the PN16 Flange, as it allows for easier access and screwing in bolts.

Bolt Size

PN16 flanges can accommodate bolts in sizes of up to 12mm, while most other types of the flange are limited to bolts no larger than 10 millimeters.

Material

The PN16 flange is made from steel, while other types of PN16 flange are often made from a variety of materials. These can include Stainless steel, Bronze, and even peek.

PN Rating

The PN rating of a PN16 flange is 16, while PN ratings on other flange types are higher. These can range from PN25 to PN100, though most PN ratings tend to be in the 30-50 range.

Overall, PN16 flanges are the best choice for PN rating, while other types of PN flanges can be used for PN ratings up to PN40 flange. PN16 flanges are the most common type of PN flange and will work with a majority of piping systems.

4. PN16 Flange Materials

There are a few different PN16 flange materials in use today. Some PN16 flanges provide better material compatibility than others.

Here are some PN16 flange materials include:

High Nickel Alloys

High nickel alloys are a popular PN16 flange material choice. These alloys provide superior corrosion resistance and heat resistance. They are also non-magnetic, making them ideal for applications where strong magnetic fields must be avoided.

Stainless Steel

Stainless steel PN16 flange materials are made from a combination of chromium and nickel. In PN16 flanges, they are used when the PN16 flange is meant to be in contact with corrosive chemicals.

Carbon Steel

PN16 Carbon Steel Flange materials are affordable, strong, and easy to machine. They also have a high resistance to oxidation and corrosion. It can be painted or galvanized to increase PN16 flange material performance.

PTFE or Polytetrafluoroethylene

PTFE or Polytetrafluoroethylene PN16 flanges are great flange materials for chemicals that react with PN16 flange materials. They are available in an extremely wide range of PN 16 flange sizes.

They are a very low coefficient of friction, so PTFE PN16 flanges provide flange with a very smooth flange surface.

Therefore, PN16 flange materials vary depending on the PN16 flange, purpose, and application.

5. PN16 Flange Dimension

PN16 flange dimensions are an important parameter to consider when choosing a flange for a piping system. PN flange dimensions are the pipe size at the flange connection. The flange dimensions pn16 are also the maximum pressure that the flange can withstand. It is a common standard for PN6 flange dimensions & PN10 flange dimensions.

The PN 16 flange dimensions is a type of flange that is used in piping systems. It has a nominal diameter of 16 inches and a thickness of 3/4 inches. It is typically used in high-pressure applications, and it is rated for a maximum working pressure of 1600 psi.

PN16 flanges are available in several different styles, and they feature a buttress root design. PN 16 flange is used in applications that use PN 10 flange, PN 16 flange is used in pressure vessels, reactor coolant pumps, and more.

6. PN16 Flange Manufacturing Process

Flanges are used to connect pipes and valves. Flanges come in a variety of sizes and specifications, the most common of which is PN16. PN16 flanges are manufactured using the following process:

Step#1 Material Cutting

The PN16 flange begins as a piece of steel that is cut to size according to the customer’s specifications.

Step#2 Heating

The steel piece is then heated to a temperature of 900 degrees Celsius in an electric furnace, at which point it is ready to be formed.

Step#3 Forging

The heated steel is then forged into the shape of a PN16 flange. This is done by pressing the steel against a die at high pressure. To create a PN16 flange, the steel must be pressed into the die with a force of at least 25 tons. Forging PN16 flanges takes about 1 hour.

Step#4 Heat Treatment

After forging PN16 flanges, they are submerged in tempering oil so that they can cool at a controlled rate. PN16 flanges are tempered at a temperature of 230 degrees Celsius. This process helps PN16 flanges achieve their final hardness and strength.

Step#5 Cutting & Shearing

The PN16 flange is then cut to the correct size and sheared to create its groove. Shearing is a process that uses a sharp blade to cut metal. PN16 flanges are typically sheared using a laser cutter. This process takes about 5 minutes.

Step#6 Inspection

PN16 flanges are inspected for quality and conformity to the customer’s specifications. Any defects are corrected before the PN16 flange is shipped to the customer. PN16 flanges are typically inspected for defects such as cracks, corrosion, bubbles, and other deformities.

PN16 flanges that do not meet the quality expectations of the customer are not used. PN16 flanges that pass inspection are then packaged and shipped to the customer.

7. The Benefits of Using PN16 Flange

A PN16 flange is a specific type of flange that is used in piping systems. PN16 flanges are made from various materials, including steel and brass. There are several benefits of using PN16 flanges including:

| 1 | PN16 Flanges Are High Quality |

| 2 | PN16 Flanges Are Durable |

| 3 | PN16 Flanges Are Easy To Install |

| 4 | PN16 Flanges Are Efficient |

PN16 Flanges Are High Quality

PN16 flanges are usually made of forged steel, which is a strong metal that is capable of withstanding high pressure without breaking. They are typically found in industrial piping systems, so they need to be strong enough to handle the high-pressure levels.

PN16 Flanges Are Durable

PN16 flanges are designed to last for several years. PN16 flanges can be subject to corrosion, but they are usually coated with zinc, which helps protect them from rust and corrosion.

PN16 flanges can also be used in many different types of piping systems, so they are designed to handle high-pressure levels without breaking, which makes PN16 flanges very durable.

PN16 Flanges Are Easy To Install

PN16 flanges are easy to install because PN16 flanges are full port, meaning that PN16 flanges have no raised surfaces on the flange. They are made to be as flat as possible, which makes PN16 flanges slip easily into place.

PN16 Flanges Are Efficient

PN16 flanges require very little clearance, which makes PN16 flanges great for systems that have tight spaces. They are also designed with fewer bolt holes, which means PN16 flanges waste less water and reduce the chances of leaks.

They have fewer ports, which also helps reduce the amount of dead space in the piping system.

Overall, PN16 flanges are very beneficial for industrial piping systems. If you’ve been looking for a new PN16 flange, be sure to contact Oflange for more information.

8. PN16 Flange Average Cost

The PN16 Flange Average Cost is something that should be considered when purchasing a PN16 Flange. The average cost is determined by the size, class, and material of the PN16 Flange.

PN16 Flanges are contoured according to the PN16 Flange specification, which is determined by class and material. The average cost can vary greatly depending on the supplier and the type of steel used.

For a high-quality PN16 flange, made from carbon steel, the average cost is around $450. However, for a lower quality PN16 flange, made from stainless steel, the average cost is around $250.

PN16 flange suppliers offer PN16 flanges in many different shapes and sizes. PN16 flange size is a major determining factor for PN16 Flange Average Cost.

9. 5 Maintenance Tips for PN16 Flange

When it comes to PN16 flange maintenance, there are a few key things that you can do to keep your equipment in good condition. Here are a few tips:

#1 Keep It Clean

Like any other device, you want to keep your flange clean. If it’s not clean, debris can get in the way of the flange being properly sealed, which can result in leaks.

#2 Check Your Gasket

If you have a metal flange, the gasket is very important. If it’s damaged or worn out, you’re likely to have leaks. The good news is that gaskets are relatively cheap, which makes it easy to just buy a new one when necessary.

#3 Lubricate the Gasket and Bolts

When you’re assembling the flange, it’s a good idea to use some kind of lubricant. This will make it much easier to put the bolts in and will prevent potential damage to the gasket.

#4 Don’t Overtighten the Bolts

Tightening the bolts too much can damage the gasket and make it more likely to leak. If you do decide to use a thread compound, be careful not to use too much.

#5 Check the Flange Regularly for Leaks

It’s important to check your flange regularly for leaks. If it starts to leak, you’ll need to fix the problem as soon as possible. Leaks can cause serious damage to your equipment, so it’s important to address them as soon as possible.

Therefore, if you take care of your PN16 flange, it’ll last you a long time. With regular cleaning and maintenance, as well as quick repairs, you’ll be able to use your flange for years.

If you want to know more about the basics of flanges, watch this video.

10. Conclusion

The PN16 Flange is the perfect tool for the job. It’s simple to use and makes a strong joint. Plus, it comes with four steel screws so you’re ready to go right out of the box.

Whether you need to connect metal or plastic parts in DIY projects, repairs, or manufacturing – this flange will get the job done right! It’s easy to use and quick which means less time spent fiddling around with tools trying to make something work when you could be doing what you love instead.

Click here now and order your PN16 Flange today!