PRODUCT FEATURES

Metal Flanges Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

Metal Flanges: A Complete Guide

If you’re in the business of manufacturing or selling metal flanges, then it’s important to be familiar with the different types of flanges available and what each is best suited for.

In this blog post, we’ll provide a complete guide to metal flanges, including an overview of the different types and their applications.

We’ll also discuss the materials used to make flanges and how to select the right type for your needs. So whether you’re a beginner or experienced professional in the world of metal flanges, read on for some valuable insights!

Table of contents

1. What Are Metal Flanges

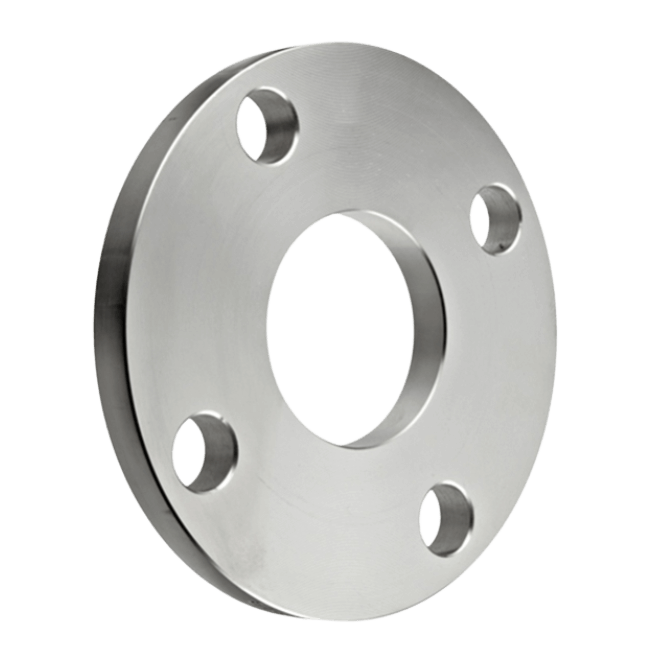

Steel pipe flanges are metal discs that are used to connect pipes and tubes. They have a hole in the center that allows them to be attached to other pipes or tubes.

Alloy steel flanges come in a variety of sizes, and they can be made from a variety of metals, including steel, aluminum, and brass.

A steel pipe with flange can also be used to seal pipes or tubes. They have a gasket that creates a tight seal between the two pieces of metal. This prevents fluid from leaking out of the pipe or tube.

There are several types of flanges, including:

- Welding neck flanges

- Slip-on flanges

- Socket weld flanges

Steel pipe with flanges is a very important component in plumbing and piping systems. They allow pipes to be connected and sealed securely, which is essential for maintaining the flow of fluid through the system.

2. Applications of Metal Flanges

Metal flanges are metal rings that can be attached to pipes and fittings.

These metal plates are used in a variety of industries, including plumbing, air conditioning, refrigeration, aerospace, automotive manufacturing, and other applications.

They may also be used on metal surfaces such as aluminum or steel plates.

There are a variety of metal flange applications, including:

Plumbing

A metal flange is often used in plumbing to create joints between different pipes. The metal flange is inserted into the pipe and then a bolt is tightened down to secure it in place. This creates a watertight seal that can withstand high pressures.

Air Conditioning & Refrigeration

Copper nickel flanges are also used in air conditioning and refrigeration applications. They can be installed on metal ducts, metal fittings, and metal pipes to create joints between different units.

Aerospace

In the aerospace industry, a steel pipe flange is often used as part of an engine exhaust system or as part of a fuel tank.

Automotive

Metal flanges are also used in the automotive industry to create joints between metal pipes and metal fittings. They are often used in exhaust systems, fuel tanks, and other applications.

Other Applications

Metal flanges can be used in a variety of other applications, including construction, water treatment, and more.

3. How Do You Install a Metal Flange Onto a Pipe or Other Object

Installing a metal flange onto a pipe can be a difficult process if you don’t have the right tools. To install a metal flange onto a pipe, you will need the following tools:

- Metal flange

- Pipe wrench

- Adjustable wrench

- Hammer

- Screwdriver

- Chisel

- Hacksaw

Loosen the Nuts on the Pipe

First, use the pipe wrench to loosen the nut on the end of the pipe. Next, use the adjustable wrench to loosen the nut on the metal flange.

Be sure to hold on to the metal flange so it doesn’t spin while you’re loosening the nut. Once both nuts are loose, use the hammer and screwdriver to remove the old metal flange.

Cut Off Excess Metal

Use the chisel and hacksaw to cut off the excess metal from the end of the pipe. Be sure to measure the correct length for the metal flange before you start cutting.

Tighten the Nuts on the Flange

Once you have cut off the excess metal, use the adjustable wrench to tighten the nut on the metal flange. Finally, use the pipe wrench to tighten the metal flange onto the pipe.

The metal flange should now be installed securely on your metal frame. Use this step-by-step guide to install metal flanges onto metal frames and enjoy a secure, sturdy structure!

4. Types of Metal Flanges

There are a variety of metal flanges available on the market, each with its own unique set of specifications. Some of the most common types of metal flanges include:

Slip-On Flanges

Also known as lap joint flanges, these flanges are typically used to connect two pipes. They feature a circular opening that slips over the end of one pipe and is held in place by a bolt or screw.

Socket Weld Flanges

These flanges have a circular socket welded to the end of the pipe, which screws into a matching threaded hole on the flange.

Threaded Flanges

These flanges have female threads on the outside diameter that allow them to be screwed into place.

Reducing Flanges

These flanges are designed to connect two pipes of different sizes, while also allowing them to be attached securely using bolts or screws.

There are many types of metal flange available in the market today, and each type has its own unique set of specifications.

Oflange also offers the following type of flanges:

- SA 105 Flange

- AWWA Flange

- Chrome Flange

- Expander Flange

- SORF Flange

- Flange 150 lbs

- GI Flange

- SS316 Flange

- DN 65 Flange

- JIS 10K Flange

- NW Flange

- RTJ Flange

- BSP Flange

Contact us at Oflange for further questions and to determine the best flange and copper nickel flange suppliers for your needs!

5. Common Problems That Can Occur When Using Metal Flanges, and How To Avoid Them

When using metal flanges, some common problems can occur. These problems can range from the flanges not fitting properly to the metal cracking.

To avoid these problems, it is important to be aware of them and take the necessary precautions.

Unfit Flanges

One of the most common problems is that the flanges may not fit properly. This can be due to a variety of reasons, such as the metal being too thick or the holes not being drilled correctly.

To avoid this problem, it is important to make sure that the metal is of the right thickness and that the holes are drilled correctly.

Cracked Metal

Another common problem is that the metal may crack. This can be due to several factors, such as the metal being too thin or the metal not being treated properly.

In order to avoid this problem, it is important to make sure that you are using metal that has been treated and that the metal is of high quality.

Damaged Flanges

It is also possible for flanges to become damaged over time. This can be due to a variety of reasons, such as the metal becoming corroded or being struck by objects.

To avoid this problem, it is important that you take care of your metal flanges and make sure that they are properly maintained.

Stained Flanges

Another common problem is that metal can become dirty and stained over time. This can be due to a variety of reasons, including the metal being in contact with moisture.

To avoid this problem, it is important that you take care of your metal flanges and make sure that they are properly cleaned.

To avoid these and other common problems, it is important to take the time to properly select and install metal flanges. It is also important to ensure that they are the right size and type for the application.

By following these simple tips, you can help ensure that your metal flanges perform flawlessly and provide long-lasting service.

6. Benefits of Metal Flanges

| 1 | Provide better flexibility |

| 2 | Fit well in tight spaces |

| 3 | Provide easy maintenance |

| 4 | Connections and fittings aren’t likely to loosen |

| 5 | More robust than traditional hydraulic fittings |

7. Installation of Metal Flanges

Installation of metal flanges is a critical process in many industries. The metal flange installations must be precise to ensure that the equipment functions as intended.

Flanges are typically installed during the manufacturing process, but they can also be installed as part of a repair or overhaul project.

Several factors must be considered when installing metal flanges. The type of metal, the thickness of the metal, and the size and shape of the flange all play a role in the installation process.

In addition, the environment in which the flange will be installed must be taken into account. The temperature, the pressure, and the type of fluid or gas that will flow through the flange must all be considered.

Select the Right Flange for the Application

The installation process begins with the selection of the right flange for the application. The flange must be the correct size and shape, and it must be made from the appropriate metal.

Determine the Bolt Pattern

Once the flange has been selected, the next step is to determine the national standard bolt pattern. This will help to ensure that there are enough bolts to secure the flange in place.

The bolts must be the correct size and type for the metal flange and the application. The bolt hole pattern must also match the flange. If there is a gasket or sealant involved, it must also be taken into account when selecting the bolts.

Identify the Location

The next step is to identify the location where the flange will be installed. This can be done by using a template or by tracing the outline of the flange onto the surface where it will be installed.

Drilling and Tapping Holes

Once the location is determined, the drilling and tapping process can begin.

The bolts are then inserted into the drilled and tapped holes. The flange is placed in position and the bolts are tightened.

Once the metal flange is secured in place, it can be installed using metal screws and nuts.

The installation process must be done carefully to ensure that the metal does not become damaged during the installation process.

The metal used for a metal flange may vary depending on what kind of equipment or device will be installed with it.

The metal can be made from steel, aluminum, or other metal alloys.

Some metal flanges are installed with plastic to help protect the metal from low-temperature corrosion and damage over time.

8. 4 Tips To Ensure the Longevity of a Metal Flange Connection

Metal flanges are an important part of many industrial and commercial applications. They are often used to connect pipes and hoses and to allow for the transfer of liquids or gases between two points.

To ensure the longevity of a metal flange connection, there are a few things that you can do.

#1 Use Identical Metal Flanges

Make sure that the blind flange pressure classes are of the same size and type. If they are not, then the piping system connection will not be as strong as it could be.

#2 Tighten the Bolts and Screws Properly

Make sure that the bolts or screws that hold the threaded flange together are tight. If they are not, then the metal flanges may come apart over time.

#3 Equip the Flanges with Strong Gaskets

Make sure that the gaskets between the metal flanges are good. If they are bad, then it will cause the metal flanges to wear out faster than normal.

#4 Pay Attention to the Flange Composition

Pay attention to how stainless steel flanges are made. You want flanged fittings that last a long time and do not rust easily. There is nothing worse than orifice flanges that get rusted in place and have to be cut off.

By following these tips, you can ensure that the weld neck flange connection will last for years.

Metal flanges are a critical part of many industrial and commercial applications, so it is important to take care of them properly. For more information on metal flanges, contact us at Oflange.

9. Cost of Metal Flanges

The cost of metal flanges can vary depending on the metal type, size, and quantity ordered. However, on average, metal flanges typically range from US$1 to US$10 per industry standard flange.

10. Metal Flanges Suppliers

The top metal flanges suppliers are those that can offer a wide range of metal flanges in various sizes and shapes, as well as provide excellent customer service.

Here are some of the top metal flanges suppliers:

Oflange

Oflange is one of the top metal flanges manufacturers that offer a wide range of metal products. Their main product line includes stainless steel, carbon steel, and alloy metal flanges in various sizes.

They also have a wide range of metal products, including metal pipe fittings, metal tube fittings, metal inserts for pipes, metal pipe connectors, metal flanges, and metal tube fittings.

In addition to their large selection of metal flange products, they also offer excellent customer service.

American Flange and Pipe, Ltd.

American Flange and Pipe, Ltd. is a leading supplier of metal flanges and other piping products. They offer a wide range of metal flanges in various sizes and shapes, including stainless steel, carbon steel, and alloy steel.

Atlantic Flange Corporation

Atlantic Flange Corporation is also one of the top metal flanges suppliers. They offer metal flanges in sizes ranging from small to large, including stainless steel and carbon steel metal flange types.

11. Conclusion

Now that you’re familiar with the different types of flanges and their applications, it’s time to learn about the materials used to make them.

Each material has its own unique benefits and drawbacks, so it’s important to select the right type for your needs.

For more information on selecting the right metal flange material, contact us today at Oflange. We’ll be happy to help you find the perfect flange for your project!