PRODUCT FEATURES

ISO Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

ISO Flange

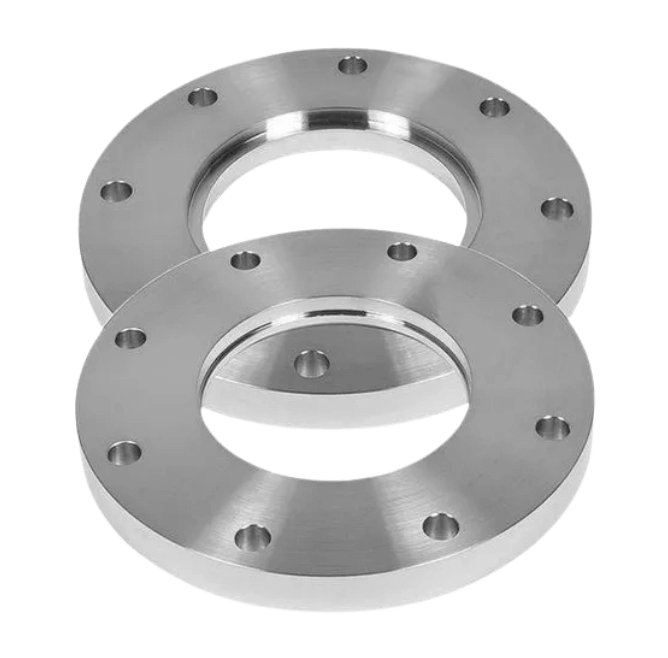

ISO flanges are a type of flange that is used to connect pipes and other fittings. They are made to the international standard ISO 6162, which ensures that they are compatible with other fittings and pipes that meet this standard. iso flanges are typically made from steel or cast iron, and they come in a variety of sizes.

ISO flanges are available in a variety of sizes and materials and are typically characterized by their flat face and raised hub. They are also often distinguished by their three equally spaced bolts holes, which are used to secure the flange to the pipe or other component.

Table of contents

1. ISO Flange Definition

An ISO flange is a type of flange that is used to connect two pieces of pipe. It is also known as an iso connection. The ISO flange is a type of welding neck flange that has a conical throat and a radiused seat.

It is named for its ISO-centric bore, which is the same size as the pipe that it connects. This allows ISO flanges to be more easily positioned on the pipe. ISO flanges are a type of flange that conforms to the ISO 6162 standard.

They are used to connect pipes and valves and come in a variety of sizes. ISO flanges are made from materials such as carbon steel, stainless steel, and aluminum. They are often used in applications where temperatures exceed 350 degrees Fahrenheit.

When working with ISO flanges, it is helpful to have a flange installation tool. This allows for the connection and disconnection of ISO flanges without specialized equipment.

All large iso flanges are made from carbon steel because this material can withstand extreme temperatures, resists corrosion, and remains strong over long periods. In addition, ISO flanges made from carbon steel can be used with many types of gasket materials, such as rubber and fiber.

2. Most Common Uses for ISO Flange

ISO flanges have a variety of applications in both the manufacturing and construction industries. Some of the most common uses for ISO flanges include:

Pipe Fittings

ISO flanges are often used as pipe fittings, as they provide a strong and secure connection between two pieces of pipe.

Flange Gaskets

ISO flanges are also used as flange gaskets, which create a seal between two pieces of metal. This helps to prevent fluid or gas leakage.

Manifolds

ISO flanges are often used as manifolds, which allow multiple tubes or pipes to be connected to a single port. This helps to improve efficiency and streamline processes.

Gasketing

ISO flanges are often used as gaskets, which provide a seal between two pieces of equipment to prevent leakage.

Bearings

ISO flanges are often used as bearings, which sit between moving parts to reduce friction and wear. This helps to improve efficiency and extend the life of machines.

3. Identifying an ISO Flange

An ISO flange is a type of flange that is standardized by the International Organization for Standardization. This type of flange is used in a variety of applications, and it can be important to be able to identify it correctly.

There are a few key features that you can look for to help you determine if a flange is an ISO flange.

Shape of the Flange

The first thing to look for is the shape of the flange. ISO flanges typically have a circular shape, and they may be either convex or concave. The edge of the flange may also be beveled.

Size of the Hole

The next thing to look for is the size of the hole in the center of the flange. ISO flanges have a hole that is typically six millimeters.

Bolt Used

The final thing to look for is the bolts that are used to hold the flanges together. ISO flanges use bolts that have a hexagonal head. The bolt may also be covered in rubber or plastic at the end, so it does not damage the surface of the flange when it is tightened down.

4. Various Types of ISO Flange

An ISO flange is a type of flange that has been standardized by the International Organization for Standardization. This type of flange is often used in piping and tubing systems.

There are several different types of ISO flanges, and it is important to be able to identify which type you are working with.

| Type | Description |

|---|---|

| Threaded Flange | This type has a threaded hole in the center, and it is often used in conjunction with a nut and bolt system. |

| Weld Neck Flange | This type has a protrusion on the neck that allows it to be welded to another component. |

| Slip-on Flange | The slip-on flange is a type of ISO flange that is designed to be easily attached to a pipe. It has a large diameter and no threads. |

| Lap Joint Flange | They are similar to slip-on flanges, but they have a threaded hole in the center that allows them to be attached with a nut and bolt system. |

| Socket Weld Flange | They are similar to slip-on flanges, but they have a socket weld instead of a threaded hole. |

Threaded Flange

The most common type of ISO flange is the threaded flange. This type has a threaded hole in the center, and it is often used in conjunction with a nut and bolt system.

Weld Neck Flange

Another common type of ISO flange is the weld neck flange. This type has a protrusion on the neck that allows it to be welded to another component.

Slip-on Flange

The slip-on flange is a type of ISO flange that is designed to be easily attached to a pipe. It has a large diameter and no threads.

To install a slip-on flange, you must first clean the pipe and then apply a sealant to the joint. You can then slip the flange onto the pipe and use a wrench to tighten it into place.

Lap Joint Flange

Lap joint flanges are a type of ISO flange that are used to connect two pieces of pipe. They are similar to slip-on flanges, but they have a threaded hole in the center that allows them to be attached with a nut and bolt system.

Lap joint flanges come in a variety of sizes and are made from materials such as carbon steel, stainless steel, and aluminum.

Socket Weld Flange

Socket Weld Flanges are a type of ISO flange that is used to connect two pieces of pipe. They are similar to slip-on flanges, but they have a socket weld instead of a threaded hole.

5. Process of Installing an ISO Flange

The process of installing an ISO flange is not a difficult one but does require some basic tools and knowledge. The following are the steps on how the process works:

Step #1 Identify the Size and Type of the ISO Flange

When installing an ISO flange, the first step is to identify the correct size and type of ISO flange for the piping system. There are a variety of ISO flanges available, so it is important to select the right one for the job.

Step #2 Clean the Pipe

Once the ISO flange has been identified, the second step is to clean the pipe and ensure that it is free of debris and burrs. The ISO flange must also be free of dirt and grease.

Step #3 Position the ISO Flange on the Pipe

The third step is to position the ISO flange on the pipe. The bolts should be tightened evenly until the flange is in place. Be sure not to over-tighten the bolts, as this can damage the pipe.

Step #4 Torque the ISO Flange Bolts

The final step is to properly torque the ISO flange bolts. This varies based on ISO flange type and material, so it is important to follow ISO flange specifications for this step.

Step #5 Test the ISO Flanges for Any Leaks

After ISO flanges have been installed, they must be tested for any leaks. It is also important to test ISO flanges during production and system startup after the installation has been completed.

6. The Advantages and Disadvantages of Using an ISO Flange

An ISO flange is a type of flange that has a raised face and a hole in the center. It is used to connect two pipes or tubes.

The ISO flange has several advantages over other types of flanges:

Durable

First, the ISO flange is very strong and can withstand high pressure. This makes it ideal for use in high-pressure applications such as pipelines and boilers.

Easy to Use

Second, the ISO flange is very easy to use. It can be easily attached to pipes or tubes using bolts or screws.

Reliable

Third, the ISO flange is very reliable and does not leak. This makes it a popular choice for many industrial applications.

However, the ISO flange also does have some disadvantages. These are:

Not Aesthetically Pleasing

First, ISO flanges are not very aesthetically pleasing and often stand out from other types of flanges. This can be a problem if the ISO flange will be visible to visitors at the facility where it is used.

Cannot Connect Larger Pipes or Tubes

Second, ISO flanges cannot connect larger pipes or tubes to smaller ones without additional parts such as reducers. This can be a problem if larger ISO flanges will be needed to connect two pipes or tubes.

Requires Additional Tools

Third, ISO flanges require additional tools such as wrenches and screwdrivers for installation. If ISO flanges are not properly installed, they could leak or fall off entirely.

7. Common ISO Flange Problems and the Best Way to Avoid Them

ISO flanges are a popular choice in piping and valve systems because of their versatility. However, ISO flanges can be prone to certain problems. Below are the most common ISO flange problems and how to avoid them.

Leaking Flanges

Leaking flanges are the number one problem with ISO flanges. This can be caused by several factors, including poor sealing surfaces, incorrect assembly, and faulty gaskets.

To prevent leaking flanges, it is important to ensure that the sealing surfaces are clean and free of contaminants, that the bolts are properly tightened, and that the gasket is correctly installed.

Burnt Gaskets

Burnt gaskets are another common ISO flange problem. This occurs when the ISO flanges are exposed to too much heat, causing the gasket material to burn and stick to the ISO flange surface.

To prevent burnt gaskets, ISO flanges should be inspected regularly for signs of damage or excessive heat exposure. It is also important to ensure that ISO flange equipment is properly cooled.

Bent Bolts

ISO flanges are often assembled with high torque bolts, which can lead to bent bolts if the ISO flange bolt or nut isn’t loosened before removing or reinstalling ISO flanges.

To avoid bent ISO flange bolts, it’s important to ensure that ISO flange bolting chart and ISO flange nut torque tools are properly calibrated to the ISO flange bolt size and ISO flange nut size.

Scratched Gasket Surfaces

ISO flanges with scratched gasket surfaces can leak or burn gaskets, leading to ISO flange problems. To avoid this problem, ISO flanges should be inspected regularly for signs of scratching, which can be caused by ISO flange bolts pulling through the ISO flanges.

8. Average Cost of ISO Flange

The average cost of an ISO flange is around $100. This price can vary depending on the size and material of the flange. ISO flanges are typically made from stainless steel, carbon steel, or aluminum.

They are used in a variety of applications, including piping and fluid systems. The ISO-f flange is a standardized flange that is used in many countries around the world.

It is named after the International Organization for Standardization table, which developed the standard pdf. The ISO k flange has several features that make it popular, including its standardized dimensions and bolt hole pattern.

The average cost of an ISO f flange varies depending on the size chart and material of the flange. Steel iso flanges tend to be less expensive than aluminum iso flanges, which in turn are less expensive than iso flanges made of high-end materials like bronze.

9. 8 Tips to Select the Right ISO Flange Dimensions for Your Needs

When selecting the right ISO flange dimensions pdf for your needs, there are a few things you need to keep in mind. Here are some tips to help you make the right choice:

#1 Make Sure the Flange Dimensions Match the Pipe

Make sure the flange dimensions match those of the pipe or fitting you’re using. Otherwise, you may not be able to connect them properly.

#2 Make Sure the Flange Can Support the Weight of the Pipe

Another thing to keep in mind is that the flange must be large enough to support the weight of the pipe or fitting. Otherwise, it may not be able to bear the load and could cause damage to the equipment.

#3 Make Sure the Flange Can Handle Pressure

Another thing to keep in mind is that the flange must be strong enough to handle the pressure of the fluid passing through it. If it’s not strong enough, it could cause damage to the equipment.

#4 Make Sure the Flange Is Durable

Another thing to keep in mind is that the flange must be made from a material that can withstand the stress of the application. If it’s not made from a durable material, it could cause damage to the equipment.

#5 Make Sure the Flange Is Compatible With the Type of Sealant You’re Using

Another thing to keep in mind is that ISO k flanges must be compatible with the type of sealant you’re using. If it’s not compatible, it could cause problems with the seal and lead to leakage.

#6 Make Sure the Flange Is of the Proper Height or Depth

Another thing to keep in mind is that ISO bf flanges must be of the proper height or depth. Otherwise, it may not be able to connect properly to the pipe or fitting.

#7 Make Sure You Have Enough Room to Work

If you have a blank vacuum flange that protrudes from the wall or floor more than 1/2 inch, make sure you have enough room to work. Otherwise, it may be difficult to install or remove the flange.

#8 Find Out if There Are Any Special Assembly Instructions

Some ISO mf flanges may have special assembly instructions. Make sure you read and follow these instructions carefully to ensure proper installation.

10. 5 Tips for Maintaining ISO Flange

When it comes to ISO vacuum flanges, there are a few tips that you can follow to maintain them properly. These tips will help to ensure that your flanges continue to function as they should and that they don’t end up causing any problems for your business.

#1 Make Sure You Use the Correct Flange

Make sure that you always use the correct type of flange for the job. This is important because using the wrong type of flange can lead to problems.

#2 Make Sure the Gasket Is in Good Condition

Keep an eye on the gaskets and make sure that they are in good condition. If the gaskets are not in good condition, they could cause leaks.

#3 Inspect the Flange Regularly

Inspect the flange regularly and check the bolts to make sure that they are still tight. Loose bolts can cause leaks and other issues, so it’s important to keep them tightened.

#4 Lubricate the Flanges Regularly

Use clean lubricants when assembling the ISO flange to ensure that you get a good seal. Using dirty lubricants can cause major problems for your ISO flanges, including causing them not to seal properly.

#5 Keep the Flanges Out of Direct Sunlight

Keep ISO flanges out of direct sunlight and away from heat sources. If ISO flanges are placed where they can get hot or where there is a lot of direct sunlight, this can cause them to break down more quickly.

If you want to know about the basics of the flange, watch this video.

11. Conclusion

The ISO 100 flange is a standard that was created to help companies avoid equipment failure. This ensures your business runs smoothly and efficiently, which saves you time and money in the long run. If you want to keep your equipment running without any problems, then this is something for you.

We have all of the information right here for you so don’t hesitate to contact us at Oflange! We must take care of our equipment because if not, there could be serious consequences down the line. That’s why we’re here to help you with anything! Contact us!