PRODUCT FEATURES

ISO 100 Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

ISO 100 Flange

ISO 100 Flange is something that you may not have heard of before, but it’s a term you’re going to want to know.

An ISO 100 flange is an important part of many different machines and industrial equipment. If you’re in the market for new machinery, or are curious about what an ISO 100 flange does, then read on.

In this article, we’ll explain everything you need to know about this vital piece of equipment. Plus, we’ll give you some tips on where to find the best prices on ISO 100 flanges. So keep reading!

Table of contents

1. ISO 100 Flange Definition and Its Uses

ISO 100 Flange is an innovative product that can give any person the ability to connect two different parts of industrial equipment without using a vacuum seal, bolts, nuts, or screws. This revolutionary product provides a quick and easy way to fix your equipment into position without causing any damage.

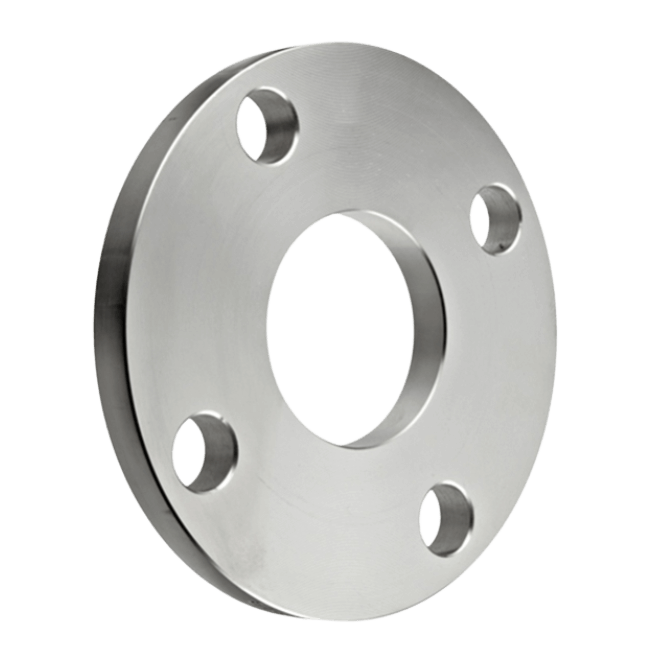

The ISO 100 flange is a steel plate with a hole cut in the center and with two holes on each of its sides. This allows you to connect any equipment with bolt holes into it for an easy fit.

2. ISO 100 Flange Features

The ISO 100 flange is a product that is made to meet the requirements of the international standard. It is a type of flange that is used in piping systems. Some of the features include:

Has a Raised Face

The ISO 100 flange has a smooth raised face. It is designated by the left-hand thread on the product. The outside diameter of the ISO flange is slightly smaller than the nominal size of the piping system.

Manufactured From a Ductile Iron Material

This ISO 100 flange is manufactured from a ductile material, which makes it one of the strongest and most reliable ISO 100 flanges.

Has a Bolt Circle That Is Larger Than the Diameter of the Hole

The ISO 100 flange has a bolt circle that is larger than the diameter of the bolt holes. This type of ISO large flange product has four bolt holes and a raised face with a 16 mm hole in it.

Threaded Hub Below the Face

This ISO 100 flange has a threaded hub that is located below the face. It allows the ISO 100 flange to be easily attached to the piping system without having to access it from underneath.

Used for Water, Steam, Gas, and Oil Piping Systems

This ISO 100 flange is used in the piping system of water, steam, gas, and oil. It is important to choose a flange that meets ISO standards so that it will function properly with the piping system.

Complies With ISO 5211 Standards

The ISO 100 flange complies with flange ISO 5211. It has a threaded hub that is located below the face, which allows it to be easily attached to the ISO 22992 piping system without having to access it from underneath. It also has a thread type designated by the left-hand thread on the product.

These are some of the ISO 100 flange features. There are different ISO 100 flanges that have their specifications. It is important to choose flanges that meet ISO standards so they will function properly with the ISO 22992 piping system.

3. ISO 100 Flange Standard Sizes

ISO 100 flange standard sizes are typically smaller than other flange sizes. This makes them ideal for applications where a smaller flange is required. They are also available in a variety of materials, which makes them versatile for many different applications and fittings.

The standard sizes of ISO 100 flanges are:

- 25 mm

- 50 mm

- 80 mm

- 100 mm

- 125 mm

- 160 mm

- 200 mm

- 250 mm

These are the standard ISO flange series sizes. However, they are also available in a variety of materials, which makes them versatile for many different applications and fittings.

4. Different Types of ISO Flanges

Aside from ISO 100 flanges, there are a number of different types of ISO flanges available in the market. These include:

| ISO 160 Flange | It has a bore size of 160mm and a diameter of 250mm. |

| ISO 63 Flange | This type of ISO flange has a bore size of 63mm and a diameter of 100mm. |

| ISO 6164 Flange | This ISO flange has a bore size of 6mm and a diameter of 160mm. |

| ISO pn10 Flange | This ISO flange has a bore size of 10mm and a diameter of 160mm. |

| ISO pn16 Flange | This ISO flange has a bore size of 16mm and a diameter of 160mm. |

| ISO 200 Flange | This ISO flange has a bore size of 200mm and a diameter of 250mm. |

ISO 160 Flange

This is the most common type of ISO flange. It has a bore size of 160mm and a diameter of 250mm. It is used in applications where the medium pressure is low and the size of the pipe is small.

ISO 63 Flange

This type of ISO flange has a bore size of 63mm and a diameter of 100mm. It is used in conjunction with ISO standard pipe fittings and is typically made from carbon steel. There are different types of flanges, which are distinguished by their method of manufacture or their purpose.

ISO 6164 Flange

This ISO flange has a bore size of 6mm and a diameter of 160mm. It is used in conjunction with ISO 6262-1 coupling.

ISO pn10 Flange

This ISO flange has a bore size of 10mm and a diameter of 160mm. It is used to connect two pieces of pipe or tubing together. The flange has a thickness of 3.5mm and is made from stainless steel. It conforms to ISO 100 standards.

ISO pn16 Flange

This ISO flange has a bore size of 16mm and a diameter of 160mm. It is used to connect two pipes together and has a thickness of 3.2mm. This ISO flange is made from stainless steel and is rated at a pressure of PN16.

ISO 200 Flange

This ISO flange has a bore size of 200mm and a diameter of 250mm. It is used in conjunction with ISO PN16 pipe fittings. This flange is made of forged steel and has a black painted finish.

Each type of ISO flange is designed for a specific purpose. Make sure to select the right ISO flange for your needs to ensure compatibility and proper sealing.

5. The Benefits of Using ISO 100 Flange

When it comes to choosing the right flange for your needs, you want to make sure you select the best option for the job. ISO 100 flanges are a great option for many different applications and offer several benefits that can make your life easier. Some of the key benefits of using ISO 100 flanges include:

Increased Versatility

ISO 100 flanges offer increased versatility, making them a good choice for a wide range of applications. It is also possible to use ISO 100 flanges for mixing, pumping, and even heat exchangers.

Increased Sealing Ability

When ISO 100 flanges are used at the end of a pipeline or vessel, they can increase sealing ability by up to 200%. This helps ensure that you can operate without worrying about leakage.

Durability

ISO 100 flanges are built to last and can withstand even the harshest conditions. It also allows ISO 100 flanges to handle a wide range of chemicals and liquids without wearing out or deteriorating due to its components.

Ease of Use

ISO 100 flanges are some of the easiest to use and install and they can be used in place of some other types of flanges. For example, ISO 100 flanges can easily replace blind holes and necked flanges.

Increase Speeds

ISO 100 flanges are built for speed, making them one of the best options when you need to get a new installation up and running quickly. This makes it perfect for oil & gas refineries, chemical plants, etc., where time is money.

Lower Operating Temperatures

When ISO 100 flanges are used in the right environment, it can lower operating temperatures by up to 50° F. This is perfect for connecting ISO 100 flanges to pipelines and vessels and makes it a great choice for those with cold storage applications.

No matter the application, ISO 100 flanges are a smart choice. If you want to find out more about ISO 100 flanges, or would like to get in touch with us for any reason, please feel free to contact our team today at Oflange.

6. ISO 100 Flange Composition

An ISO 100 flange is a type of flange that is made to meet the requirements of the International Organization for Standardization. It is made from high-quality materials and is designed to be strong and durable. It is also corrosion-resistant, making it a good choice for use in harsh environments.

The composition of an ISO 100 flange are as follows:

Material

The ISO 100 flange is made from a high-quality material called AISI 316L stainless steel, 304 stainless steel, and aluminum. This type of metal alloy is corrosion resistant as well as strong, making it ideal for use in harsh environments or where the flanges are exposed to chemicals.

Threads

ISO 100 flanges have 3/4-inch NPT (national pipe thread) male threads. The threads are designed to be compatible with other hardware that has the same specs. The bolts should also be made from AISI 316L stainless steel and should likewise comply with ISO MF specifications for bolt materials.

Thickness

ISO 100 flanges have a thickness of .120″ (about 3 mm). It should be noted that the flange’s thickness may vary depending on its function within a larger whole.

Welding

The welds for an ISO 100 flange are done using argon gas to prevent oxidation and increase the quality of the finished product. The welding method is a combination of TIG welding and orbital welding.

This is a common method used when manufacturing flanges because it enables the maximum amount of control when joining different parts together.

Finish

The finished product has a high-quality surface, without any burrs or rough spots, which could cause stress points in larger assemblies. The finish is also resistant to damage from chemicals or weather.

Dimensions

The ISO flange dimensions are 3/4 inches wide by 1-1/8 inches high. The bolt holes will be centered on one side, with male threads on the other. This type of design is compatible with piping that also has female NPT threads.

The distance from the center of the flange’s holes to its outer edge, as well as the thickness and width, will comply with ISO specifications.

Centering Ring

An ISO 100 flange will have a centering ring that helps to keep it centered on the pipe or other hardware it is being attached to. The centering ring is made from the same material as the flange and has the same dimensions.

7. Manufacturing Process of ISO 100 Flange

The manufacture of an ISO 100 flange generally involves the use of a die. The die is used to create the desired shape and size of the flange. The flange is then cut from the sheet metal using a punch press. The edges are then trimmed and any burrs are removed. The flange is then cleaned and inspected for defects.

The manufacturing process of an ISO 100 flange is as follows:

Step #1 Create the Blank Flange

The first step of the manufacturing process of an ISO 100 flange is to create the initial blank flange. The shape and size of the blank flange will depend on the type, size, shape, and depth of the desired ISO 100 flanges.

Step #2 Create a Die With Corresponding Shape and Size

A punch press is then used to create a die that corresponds with the shape and size of the blank flange. This die is then placed into a stamping press, which will decide the amount of pressure that is applied to the metal during the next step.

Step #3 Punch and Form Flange Taking Shape

The metal sheet is then inserted into between two dies that correspond with the design of the flange. This process will press down on the metal sheet and flatten it until the desired shape and thickness are created. At this point, a border or lip is left around the edge of the flange to add support.

Step #4 Trim Sheet Metal Around Flange

The excess material from around the flange is then removed using a punch press. The punch presses will remove the extra material and create a cut line, and leave any excess metal in place around the border of the flange.

Step #5 Punch-Out Remaining Metal Edges

After the sheet metal has been pressed to take shape, it must be punched out where any excess metal remains. This punching out process is completed with a punch press to ensure the appropriate pressure and pressure distribution are applied at this point of the manufacturing process.

Step #6 Remove Any Excess Material

Once all excess material has been removed, any extra pieces or burrs that were created during the punching process are then removed using a chipping press.

Step #7 Inspect for Imperfections

The final step of the manufacturing process of ISO 100 flanges is to perform a quality inspection on the finished product. The inspector will check the inside and outside of the flange for any imperfections or blemishes that may have been left behind during manufacturing.

Step #8 Clean

The final step of the ISO 100 flange manufacturing process is to clean off all of the residual materials left on the flange. The final product is then packaged and prepared for shipment to a customer or supplier.

The manufacturing process for an ISO 100 flange is fairly simple, but the quality control process is quite extensive. After the manufacturing process is complete, any flaws or imperfections will ensure that the product cannot be sold to customers.

8. ISO 100 Flange Average Price

The average price of an ISO 100 flange is about $157. However, there is a large range of prices for this type of flange. The cheapest option is about $50, while the most expensive option is about $250. Several factors can affect the price of an ISO vacuum flange, including the material, size, and brand.

If you want an exact quote on an ISO 100 flange, you can contact us at Oflange. We will be glad to provide you with a quote and answer any questions you might have.

9. 3 Tips to Choose the Right ISO 100 Flange for Your Needs

When it comes to ISO 100 flange, you need the right tool for your needs. This means there is a lot out there and it can be overwhelming when choosing the one that suits you best.

Here are 3 tips on choosing ISO 100 flange:

#1 Do Your Research

The first ISO 100 flange you should look at is the reviews. Reviews will help you decide on the ISO 100 flange that has worked for other people. Often, reviews can be more useful than the product’s website. This is because ISO 100 flange reviews are written from the perspective of users, giving you a more complete picture.

#2 Choose ISO 100 Flange from a Reputable Manufacturer

ISO 100 flange from a reputable manufacturer will sometimes be more expensive than from a manufacturer that is not as reputable. ISO 100 flange from a reputable manufacturer has been lab-tested for quality and is made in ISO 100 flange facilities that are up to par.

#3 Evaluate ISO 100 Flange Price versus ISO 100 Flange Quality

The ISO 100 flange price should not be the only thing you should consider. ISO 100 flange that is more expensive could have features that are worth it, even if they do cost more. It should always follow this ISO 100 flange rule: “you get what you pay for”.

No matter ISO 100 flange you decide to, make sure it is the right flange for you. It should be chosen based on your needs and budget.

10. 3 Tips for Installing and Using ISO 100 Flange Safely and Effectively

When it comes to installing and using ISO 100 flange, there are a few tips that you can keep in mind to ensure safe and effective use. Here are 3 tips to get you started:

#1 Right Size for the Pipe

Make sure that the flange is the right size for the pipe. It’s important to choose the right size flange so that it can properly seal against the pipe.

#2 Lubricate the Gasket and Flange Joint

Lubricate the gasket and flange joint before installation. This will help to create a tight seal and prevent leakage.

#3 Use Clamps or Straps To Secure the Flange

Use clamps or straps to secure the flange in place while it’s being tightened. This will help to prevent damage to the flange and ensure a tight seal.

By following these 3 tips, you’ll be able to safely and effectively install and use ISO 100 flanges. With a little practice, these steps should become second nature.

To know the basics of flanges, watch this video.

11. Conclusion

ISO 100 flange can be used to safely and effectively transport liquids at varying pressures. When you’re ready to start using ISO 100 flanges, be sure that you are familiar with the steps for installation and use.

If you’re looking for a high-quality, durable flange that can be used in a variety of industries, the ISO 100 is always a good option. At Oflange, we carry a wide selection of ISO 100 flanges and can help you find the perfect one for your needs. Contact us today to learn more about our products!