PRODUCT FEATURES

Forged Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

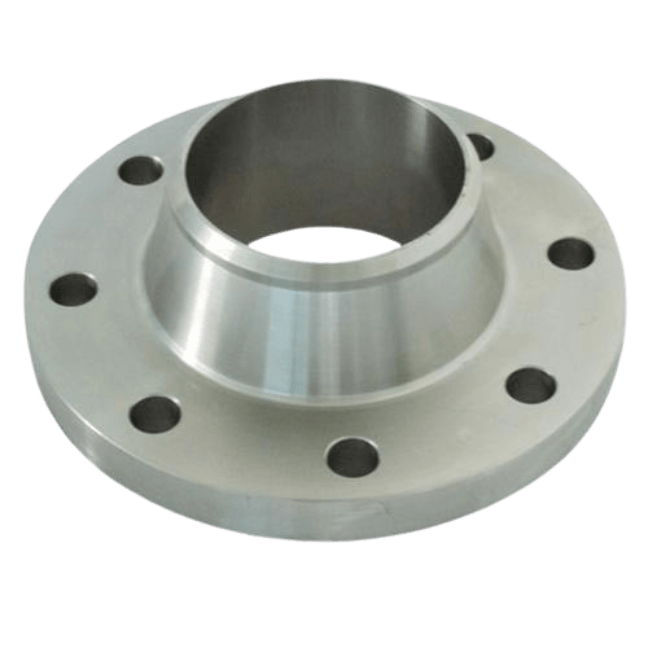

Forged Flange

Looking for a cheap, affordable option for your next project or piping business? Look no further than the Forged Flange.

These flanges can be used in a variety of applications including but not limited to pressure vessels, heat exchangers, chemical processing equipment, and more!

Forged flanges offer adaptable, cost-effective, and flexible flanges for a variety of piping and sealing applications.

Table of contents

1. Forged Flange Definition and Its Uses

A Forged Flange is a type of flange that is made from a piece of metal that has been heated and then shaped by hammering.

Forged flanges are usually stronger than other types of flanges and are often used in applications where high pressure or high stress is present.

Forged flanges are also popular because they can be customized to fit specific needs, and they are often less expensive than other types of flanges.

Forging a flange starts by forging flanges made from carbon steel, although flange forge can be made with other materials too. A Forged Carbon Steel Flange is usually very strong and durable.

Forged flanges have many different types of uses, but they are most common in oil pipelines, pressurized tanks or storage compartments, steam equipment, and nuclear power plant applications.

Forged flanges are also often used in the construction of ships, submarines, and other types of water vessels.

2. The Manufacturing Process of a Forged Flange

Forged flanges have a straightforward manufacturing process. Here are the steps:

Step#1 Creating Blank Molds

The first step in the manufacturing process of a forged flange is to create the blank. The blank is a piece of metal that is the same size and shape as the final product. It is created by using a mold to form the metal into the desired shape.

Step#2 Forging the Blank

The next step in the manufacturing process is to forge the blank. Forging is a process that uses heat and pressure to shape the metal. The forge will heat up the metal until it is red hot.

Step#3 Place Metal into the Die

Then, the metal will be placed in a die, which is a tool that has the shape of the desired product. The die will press down on the metal, causing it to take on the shape of the die.

Step#4 Die-Forging the Flange

Finally, the forged flange must go through die-forging which will give it its desirable physical properties. Die Forging is a secondary forging process that increases the strength of the metal to as much as 20 times greater than its original state.

This is done by increasing compressive residual stress in certain areas of the forged flange and by introducing some shear stresses in certain areas.

This will cause the flange to be extra strong in the desired area and less likely to suffer from fatigue cracks.

3. The Different Types of Forging Techniques

There are many different types of forging techniques that can be used to create different types of metal products.

Forged flanges, for example, can be created using several different forging techniques. Some of the most common forging techniques include the following:

Hammer Forging

This is the most basic type of forging, and it involves pounding the metal into shape with a hammer. This technique is often used to create simple shapes like squares or rectangles.

Die Forging

This technique uses metal dies to shape the metal. The dies are shaped like the desired product, and the metal is forced into them to create the desired shape.

Roll Forging

This technique uses large rollers to press the metal into shape. For example, the metal can be rolled into a long sheet and then cut to the appropriate length after it is in its final shape.

Press Forging

Press forging of metal objects using a machine that applies pressure to the item being forged.

For example, a screwdriver may be formed from a long piece of steel by placing it between two dies, one die containing the shape of the handle and another containing the shape of the tip, and applying force to the piece with a hydraulic press.

4. Advantages and Disadvantages of Forged Flanges

Forged steel flanges are extremely popular for piping and sealing solutions in the construction and chemical industry. Here are some of its advantages and disadvantages:

| Advantages | Disadvantages |

|---|---|

| High Strength Forged flanges are strong. Forging is typically done with a smaller cross-section to be able to create the desired mechanical properties, which makes them stronger than other flange options. | Expensive One of the disadvantages of forged flanges is that they can be more expensive than other types of flanges, and they may not be as readily available. Forging is an involved process that requires high-quality steel, clean lines, and sharp edges, all of which add time and cost to making new flanges. |

| Consistency Forging creates more consistent dimensions than other common types of manufacturing processes. It is also capable of creating smooth transition areas between parts, which means that there are no abrupt changes in the pipe or flange shape. Forging is also good at producing flanges that are perfectly flat and smooth, meaning that there is no excess flash or roughness on the flange surface. | Hard to Install Forged flanges can be harder to install since they must be ground down to fit whatever part they are connecting to, and the pressure levels needed for an installation may damage them or cause them not to seal properly. |

| Adaptability The forging process can also create shapes that would be difficult to achieve any other way, making forging very adaptable in terms of what it can produce. This means that steel pipes conveying mediums can create flanges that are very strong but are also lighter in weight. Carbon steel forged flanges can be made with complex shapes, which allows them to fit into tight spaces that other types of flanges cannot. | |

| Strong Resistance to Leaks Forging flange can also control the amount of expansion or contraction that occurs with changes in steel pipes temperature, which helps to prevent leaks. | |

| Versatility Forged flanges can be made from a vast majority of materials, including carbon steel, alloy steel, stainless steel, aluminum, and more. Forging can also be done with all the different materials to create parts for many different applications. Forged flanges are available in configurations that are no longer common with other types of piping system options, which makes them very versatile. |

5. Applications of Forged Flanges in Various Industries

Many different industries make use of forged flanges. Some of the most common applications include:

Oil and Gas Industry

Forged flanges are often used in oil and gas pipelines to connect different parts of the pipeline. They are also used in oil refineries and other processing facilities.

Marine Industry

Forged flanges are commonly used in marine applications where high pressure and temperature are a concern. For example, they are used in steam turbines and boilers.

Power Generation Industry

Forged flanges are used in power generation plants to connect pipes carrying hot water or steam. Forged flanges can also be used in nuclear power plants.

For example, they are often found connecting the primary coolant loops of these plants or to other parts of the plant.

Chemical Industry

Forged flanges are commonly used in piping systems that transport corrosive liquids like acids and alkalines.

For instance, they are used in large-scale petrochemical plants, oil refineries (including crude oil distillation units), natural gas processing plants, etc.

Food Industry

Forged flanges can be found connecting pipelines that transport food products like milk and wine. For example, they regulate the flow of liquid substances during solid particle separation or size reduction.

Forged flanges are also commonly used within the dairy industry to connect pipes carrying products between different parts of a plant (for instance, inside pasteurizers).

Construction Industry

Forged flanges are commonly found in building construction as well as plumbing applications.

For instance, they help carry water from different sources throughout a building. Forged flanges are also often used to connect different pipes throughout a building.

6. Forged Flange Average Cost

If you purchase off-the-shelf from a forged flanges manufacturer then the prices will range between US$5-US$20 per forged flange. For custom-made flanges, it can be as much as US$30 each.

The slip on forged steel flange price can vary depending on where you purchase your forged flanges from or if they are custom-made.

7. Where to Purchase Forged Flange in Bulk

There are a few places where you can purchase forged flange in bulk. Forged flanges are usually used in high-pressure applications, so it’s important to find a supplier who can meet your needs.

Some of the best places to buy forged flanges include:

Oflange

Oflange is a global manufacturer of pipe flanges and has been in business for many years.

Providing innovative and high-quality solutions for use in applications such as pipeline systems, oil wells, etc., they manufacture top-quality and affordable products for their customers.

McMaster-Carr

McMaster-Carr is another place where you can buy Forged Flange. They have a large selection of forged flange products for sale along with many other kinds of industrial products.

8. 3 Tips to Select the Right Forged Flange for Your Needs

When selecting a forged flange, it is important to consider the function that the flange will serve. Here are some tips to help you select the right forged flange for your needs:

#1 Choose the Right Size Flange

The size of the flange should be based on the size of the pipe that it will be attached to.

#2 Consider the Correct Flange Material

Make sure that the flange is made of the correct material for your application. For example, if you need a flange for high pressure or high-temperature applications, you will need to choose a forged flange made from high-quality materials.

#3 Check the Certifications

Check the certification and compliance of the forged flange. The forged flange should meet all applicable standards and regulations.

9. Conclusion

Forged flanges are the most adaptable, cost-effective, and flexible option on the market. They offer an affordable solution to your next project or piping business.

You will never have to worry about finding another product that offers this level of flexibility at such an affordable price point again.

Click here now so we can help make your life easier by offering these amazing forged flanges!