PRODUCT FEATURES

Flat Face Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

All You Need to Know About Flat Face Flange

If you are in the market for a flat face flange, you may be wondering what all the fuss is about. What are the benefits of using a flat face flange, and how can you make sure you’re choosing the right one?

In this blog post, we will take a look at everything you need to know about flat face flanges. We will discuss what they are, how they differ from other types of flanges, and some of the reasons why you might want to choose one for your project.

By the end of this post, you will have a clear idea of what flat face flanges are all about and whether or not they’re right for your needs.

Table of contents

1. What Is a Flat Face Flange

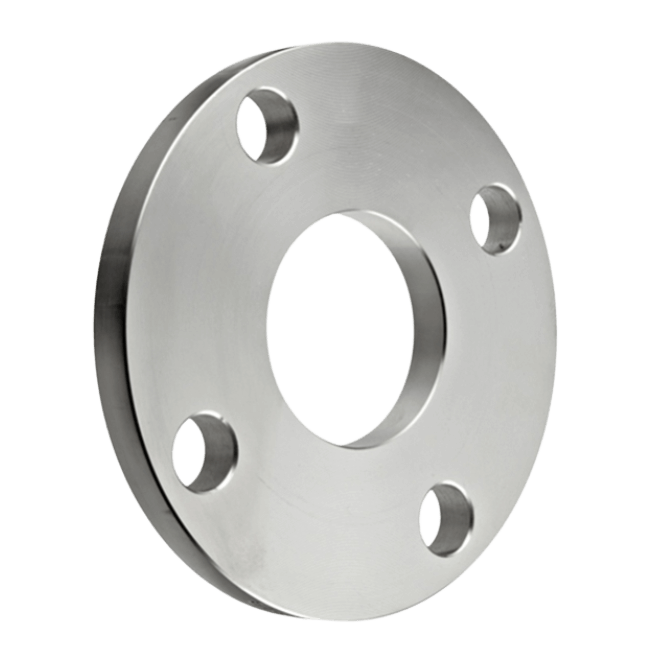

A flat face flange, also known as an FF flange, is a flange with no ridge, unlike a raised face or ring type joint flange. Because of the flat surface, the gasket may make complete contact with the mating surface.

The flat face’s purpose is to reduce the bending moment applied to the flange when the bolts are torqued. This bending moment can easily break the flange when employing cast iron or fiberglass flanges.

Flat-facing flanges are typically utilized in low-pressure, low-temperature applications, such as water treatment or pump suction flanges. When the piping or piping components are fragile, such as plastic, fiberglass, or cast iron, flat face flanges are commonly used.

Flat face flanges come in a variety of sizes and styles and can be made from a variety of materials including steel, aluminum, and stainless steel. They are typically installed with bolts or screws and can be used with a variety of piping materials including PVC, ABS, and polypropylene.

Weld neck flat face, slip-on flat face, socket weld flat face, and threaded flat face flanges are the most common types. These are typically found in ANSI flat face flange 150 and 300 classifications.

Flat face flanges are commonly used in sanitary applications, where a tight seal is essential to prevent contamination. They are also used in other industries where a flush seal is important, such as petrochemical and aerospace.

2. Benefits of Using Flat Face Flange

These are very helpful for people to make the right choice of the flange. There are a few key benefits of using flat face flanges that you should be aware of. Here are four of the most important:

| 1 | Increased Strength and Durability |

| 2 | Reduced Leakage |

| 3 | Easy Installation |

| 4 | Easy Installation |

Increased Strength and Durability

A flat face flange offers increased strength and durability over a traditional raised face flange. This is because there is less surface area for the bolts to grip, making it less likely that they will loosen over time.

Reduced Leakage

Flat face flanges also help to reduce leakage, as there is no recess for the flat face flange gasket to sit in. This means that there is less chance of the gasket becoming compressed and leaking.

Easy Installation

Flat face flanges are also much easier to install than traditional raised face flanges, as they do not require any additional machining. This makes them a great option for applications where time and labor are limited.

Cost-Effective

Another great benefit of flat face flanges is that they are typically much less expensive than traditional raised face flanges. This is because they require less material and labor to produce.

If you are looking for a strong, durable, and cost-effective option for your next project, flat face flanges are a great choice.

3. 5 Tips To Know if Flat Face Flange Is Installed Correctly

Installing flange correctly helps minimize the chances of leakage, bolts coming loose, and potential for failure. Here are some tips to know if a flat face flange is installed correctly.

#1 Make Sure the Gasket is Properly Seated

One of the most important things to check when installing a flat face flange is that the gasket is properly seated. If it isn’t, you will experience leakage. To ensure that the gasket is correctly in place, use a flat head screwdriver to press it into the groove around the edge of the flange.

#2 Make Sure the Bolts are Tightened Properly

Another important thing to check when installing a flat face flange is that the bolts are tightened properly. If they aren’t, you will experience leakage. To make sure the bolts are tight enough, use a torque wrench and tighten them to the manufacturer’s specifications.

#3 Check the Flatness of the Flange

It is also important to check the flatness of the flange before installing it. If it isn’t flat, you will experience leakage. To check the flatness of the flange, use a straight edge and compare it to the surface of the flange. If there are more than 0.015 inches of difference, the flange is not flat and should not be used.

#4 Make Sure the Flange is the Correct Size

It is also important to make sure that you are using the correct size flat face flange. If it is too small or too large, you will experience leakage. To make sure you are using the correct size, refer to the manufacturer’s specifications.

#5 Check for Leaks and Make Adjustments

After you have installed the flat face flange, it is important to check for leaks. To do this, turn on the water and look for any dripping or pooling around the flange. If you see any, tighten the bolts and check again. If there are still leaks, replace the gasket and try again.

If you follow these tips, you can be sure that your flat face flange is installed correctly and will provide years of leak-free service.

4. Types of Flat Face Flange

There are different types of flat face flange. Each has its features and designs that make it more suitable for certain applications. Here are some of the most common types of flat face flange:

Raised Face Flange (RF)

RF flange means raised face. It is the most common type of flat face flange and is used in a wide variety of applications. RF flanges have a raised ridge around the edge of the flange that helps to seal the gasket and prevent leakage.

A flange RF type can be used with a variety of flange gaskets, from flat to semi-metallic and metallic kinds (such as jacketed and spiral wound gaskets), in either ring or full-face configurations.

The main purpose of an RF flange is to concentrate the pressure of the two mating flanges on a tiny surface, hence improving the seal’s strength. At least for petrochemical applications, raised face flanges are the most popular.

Ring Joint Flange (RTJ)

A ring joint flange (RTJ) is similar to a raised face flange in that the gasket surface area is located above the bolting line. However, a ring joint flange has a groove around its edge which mates with a corresponding projection on the mating flat face flange.

When a metal-to-metal seal between the mating flanges is required (which is a requirement for high-pressure and high-temperature applications, i.e. above 700/800 C°), a ring joint flange (RTJ) is employed.

Ring joint flanges are typically used for high-pressure or cryogenic applications. They are available in a variety of materials, including stainless steel and titanium.

Lap Joint Flange

A lap joint flange (LJ) is a type of flat face flange that has a projecting lug on one side which mates with a corresponding recess in the mating flat face flange.

This type of flange is often used when the space between the two mating flanges is limited. Lap joint flanges are available in a variety of materials, including stainless steel and titanium.

Male and Female Flange (M&F)

A male and female flange (M&F) is a type of flat face flange that has a protrusion on one side which mates with a corresponding recess in the mating flat face flange.

The male flange has a region that extends beyond its face area, while the female flange has a comparable depression drilled into the facing surface. Each of the female and male faces is 3/16″ deep and 1/4″ high, with a clean finish on both.

This type of flange is often used when the space between the two mating flanges is limited. Male and female flanges are available in a variety of materials, including stainless steel and titanium.

Tongue and Groove Flange (T&G)

Two tongue and groove flanges (T&G face) precisely suit one another: one has a raised ring, the other has a groove, and they can be simply bonded (the tongue enters the groove and seals the joint). Both large and small tongue and groove flanges are standardized.

There are several flange FF types available in the market, each has its advantages and disadvantages. It is important to choose the right type of flat face flange for your application.

For more types of flanges, you can watch this video.

5. Raised Face Flange vs. Flat Face Flange

The main difference between a raised face flange vs flat face flange is the height of the contact surface. A raised face flange has a gasket surface that is located above the bolting line, making it easier to identify. A flat face flange should never be mated with a raised face flange, according to ASME B31.

When a flat face flange is mated with another flat face flange, the gasket surface area is located below the bolting line which can cause leakage.

These are two of the most frequent flange face configurations. The ring-type and the full-face gasket are the two types of gaskets that can be used to seal them.

6. Most Common Uses for Flat Face Flanges

Flat face flanges are one of the most versatile types of flanges and have a wide range of uses. They are commonly used in the following:

Connecting Pipeline to a Valve

Flat face flanges are the most common type of flange used in pipelines. They are designed to connect pipes, valves, and other equipment with flat surfaces.

Construction of Manifolds

Flat face flanges are also commonly used in the construction of manifolds. A manifold is a collection of pipelines that branch off from a single pipe. The flat face flange allows for easy connection and disconnection of the pipes.

Reducing Pressure Drop

A flat face flange can also be used to reduce pressure drops in a pipeline. When a pipeline is carrying a high volume of fluid, the pressure can drop as the fluid flows through the pipe. A flat face flange can be used to reduce this pressure drop by providing a smooth surface for the fluid to flow over.

7. How To Identify a Flat Face Flange

A flat face flange can be identified by its lack of a raised surface. The contact surface is flat, and the gasket surface area is located below the bolting line.

Flat face flanges are available in a variety of materials, including stainless steel and titanium. They are typically used in applications where a metal-to-metal seal is required.

8. Type of Bolts or Screws Used To Install a Flat Face Flange

The type of bolts or screws used to install a flange is also an important consideration. They differ from each other in terms of the size and type of head they have. Here are the types of bolts and screws used to install a flat face flange.

- Socket head cap screws

- Hex head bolts

- Allen head bolts

- Slotted screws

- Phillips screws

When installing a flat face flange, it is important to use the correct type of bolt or screw. Using the wrong type of bolt or screw can cause damage to the flat face flange.

9. Restrictions on the Use of Flat Face Flanges

It is common to have restrictions on the use of flat face flanges. Some applications are not suitable for flat face flanges due to the risk of leakage. Here are some of the restrictions on the use of flat face flanges.

- Flanges must only be used in applications where flat face sealing is possible.

- The bolt circles on flat face flanges must coincide with the bolt circle of the mating part.

- Only gaskets specifically designed for flat face flanges should be used.

- The maximum allowable pressure differential across a flat face flange is limited to 0.25 bar (or 36 psi).

- The flat face flange must be positioned so that the sealing surface is in line with the fluid flow.

- Flanges must only be used in conjunction with mating parts that have a flat face seal groove.

If you are unsure about whether or not a flat face flange is suitable for your application, please consult a qualified engineer.

10. Conclusion

A flat face flange is a type of flange that has a flat surface on the end opposite the hub. This type of flange is often used in piping and valve systems, as it provides a secure connection between two pieces of equipment.

It is widely used in the petrochemical and pharmaceutical industries, as well as in other process-related applications. So if you are looking for a strong secured connection between two pipes, a flat face flange is the way to go.

If you have any questions about flat face flange, please do not hesitate to contact us at Oflange. We will be more than happy to help you.