PRODUCT FEATURES

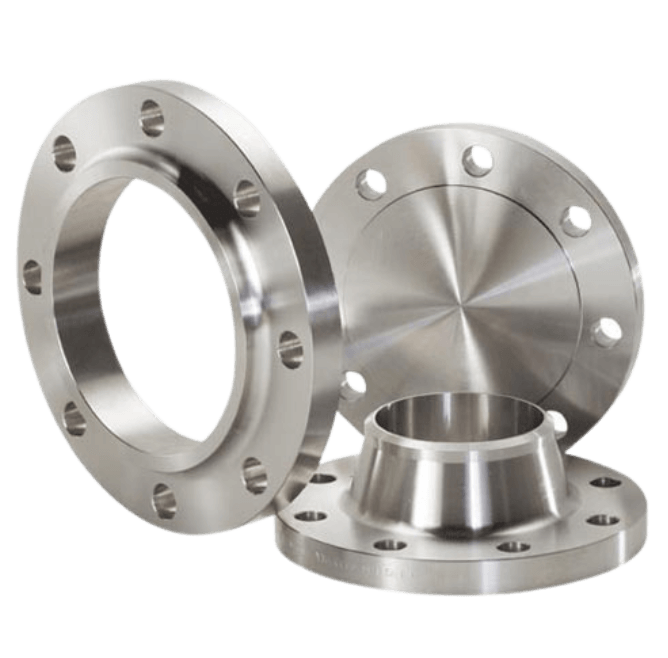

Duplex Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

Duplex Flange: What Is It and Its Applications

If you are in the engineering or manufacturing business, then you have likely heard of duplex flanges. But what are they and what are their applications?

In this article, we will explore the definition of a duplex flange, as well as its uses in various industries. We will also discuss the different types of duplex flanges and how to select the right one for your needs. So if you’re curious about this handy little device, read on!

Table of contents

1. What Is a Duplex Flange and What Are Its Uses

A duplex flange is a type of flange that is used to join two pipes or tubes together. It is a two-part flange that has a male and female component, and it is used to create a seal between the two pipes or tubes.

Duplex flanges are often used in plumbing applications, and they are also used in chemical and pharmaceutical applications.

Super duplex flanges are available in a variety of sizes, such as duplex 2205 f51, duplex 2205 flanges, a182 f51 flange and they are made from a variety of materials.

They are also available in a variety of styles, including threaded and non-threaded styles. The type of duplex flange that you choose will depend on the application that you are using it for.

2. Applications of Duplex Flange

Duplex flanges are used in a variety of applications. Some common applications include:

- Pipe Joining

- Pressure Vessel

- Heat Exchanger

- Condenser

- Structural Support

Duplex flanges are made from two different metals, which are welded together. This makes the duplex flange very strong and durable. It can withstand a lot of pressure and is resistant to corrosion.

The duplex flange has become a popular choice in many industries because of its strength and durability.

It is ideal for applications that require high pressure and corrosion resistance. If you are looking for a strong and durable flange, the duplex flange is a great option.

If you have any questions about duplex flanges or need help selecting the right flange for your application, contact us today at Oflange.com. We would be happy to help you find the duplex flange that meets your needs.

3. Installing a Duplex Flange

Installing a duplex flange may seem like a daunting task, but with a little preparation, it can be done relatively easily.

Clean the Surface of the Flange

The first step is to make sure that the surface you are installing the flange on is clean and free of debris. If there is any grease or other contaminants on the surface, they will need to be removed before installation can proceed.

Mark the Holes that will be Drilled

Once the surface is ready, the next step is to place the flange in the desired location and mark the holes that will need to be drilled. Be sure to use a level when marking the holes, so that the flange is properly aligned.

Drill the Holes using a Bit

Drill the holes using a drill bit that is slightly smaller than the screws that will be used to attach the flange.

Attach the Flange to the Surface

Once the holes have been drilled, it’s time to attach the flange to the surface. Start by inserting the screws into the holes and then tightening them until they are firmly in place.

Be sure not to over-tighten the screws, as this can damage the surface of the flange.

If everything has been installed correctly, the duplex flange will be securely in place and ready for use.

4. When To Use a Duplex Flange

A duplex flange is a type of flange that is used in piping and plumbing systems. It is a two-part flange that is bolted together to create a seal between two pipes.

Duplex flanges are often used in high-pressure applications, such as in oil and gas pipelines. They are also used in chemical and petrochemical plants, as well as in power plants.

There are several factors that you should consider when deciding whether to use a duplex flange.

The most important factor is the pressure of the fluid that is passing through the pipes.

You should also consider the temperature of the fluid and the material of the pipes.

Duplex flanges are typically used in applications where the pressure is greater than 400 pounds per square inch (psi). If the pressure is less than 400 psi, you may be able to use a standard flange instead.

The temperature of the fluid should also be considered. Duplex flanges are typically used in high-temperature applications, but they can also be used in low-temperature applications.

The material of the pipes is also important. Duplex flanges are typically used in applications where the pipes are made of high-strength material, such as stainless steel or carbon steel.

If you are unsure whether to use a duplex flange or a standard flange, contact us at Oflange. We can help you determine the best flange for your application.

5. Benefits of Using a Duplex Flange

A duplex flange is a two-piece flange that is often used in piping systems. It is comprised of a mating surface and a gasket surface. The advantages of using a duplex flange include:

Increased Strength

A duplex flange can withstand higher pressure and temperatures than a standard flange.

Easier Assembly

A duplex flange can be easily assembled and disassembled, which makes it ideal for use in tight spaces.

Increased Leak Resistance

The two-piece design of a duplex flange creates a tighter seal, which results in less leakage.

If you are looking for a strong and leak-resistant flange, then a duplex flange is the ideal option.

6. 10 Tips on How To Care for Your Duplex Flange

Duplex flanges are a type of flange that is composed of two parts that are bolted or clamped together. It is important to take care of your duplex flange so that it lasts for a long time. Here are some tips on how to care for your duplex flange:

| 1 | Be Cautious when Handling Flanges |

| 2 | Inspect the Flanges Before Use |

| 3 | Check the Gaskets and Seals |

| 4 | Use Only Authorized Fittings and Components |

| 5 | Properly Secure the Flanges |

| 6 | Tighten the Clamps Carefully |

| 7 | Clean the Flanges Regularly |

| 8 | Keep the Bolts Lubricated |

| 9 | Check the Alignments Before Working |

| 10 | Store Flanges in a Dry Place |

#1 Be Cautious when Handling Flanges

Always use caution when handling duplex flanges, as they are heavy and can be easily damaged.

#2 Inspect the Flanges Before Use

Inspect the duplex flange for damage before each use. If there is any damage, do not use the duplex flange and contact a qualified professional.

#3 Check the Gaskets and Seals

Make sure the gaskets and seals are in good condition and properly in place before each use. The DIN flanges should be checked for crevice corrosion and stress corrosion cracking regularly.

#4 Use Only Authorized Fittings and Components

Only use authorized duplex flange fittings and components. Unauthorized parts may not fit, or even damage the pipings if not worked upon, early on.

#5 Properly Secure the Flanges

Make sure the plate flange is properly secured to the piping system before each use.

#6 Tighten the Clamps Carefully

Make sure that the bolts or clamps are tight so that the duplex flange doesn’t come apart through stress corrosion cracking resistance.

#7 Clean the Flanges Regularly

Clean the duplex flange regularly so that it doesn’t corrode.

#8 Keep the Bolts Lubricated

Lubricate the bolts or clamps regularly so that they don’t rust.

#9 Check the Alignments Before Working

Make sure that the duplex flange is properly aligned before bolting or clamping it together.

#10 Store Flanges in a Dry Place

If the duplex flange is not being used, make sure to store it in a dry place.

These are just some of the tips on how to care for your duplex flange. Make sure to consult the manufacturer’s instructions for more specific information. By following these tips, you can ensure that your duplex flange lasts for a long time.

7. Types of Duplex Flange

Duplex steel flanges are a type of flange that is used in piping and tubing systems. They are made from a duplex stainless steel flanges material and come in a variety of sizes and shapes.

Each type of ASTM A182 duplex steel has its unique features and benefits. There are several different types of duplex flanges, including:

Blind Flanges

Blind duplex steel screwed flanges are used to close off the end of a piping system or tube.

Lap Joint Flanges

Lap joint flanges have a protrusion on one side that allows them to be joined with another lap joint flange.

Spectacle Blind Flanges

A spectacle blind socket weld flange has two bolt holes that are used to attach the flange to a pipe.

Slip-on Flanges

Duplex steel Slip-on flanges can be easily attached to a pipe without the need for welding or threading.

Threaded Flanges

Threaded flange pressure class flanges have a threaded hole in the center that allows them to be attached to a pipe with a bolt.

Choosing the right duplex steel weld neck flange is essential for ensuring the safety and efficiency of your piping or tubing system.

Make sure to consult with a qualified engineer to determine which type of duplex flange is best for your specific application.

8. Manufacturers of Duplex Flange

Some of the Manufacturers Companies of Duplex Flange include:

Oflange

Oflange is a global manufacturer of pipe flanges and has been in business for several years.

We provide innovative and high-quality products for use in applications such as pipeline systems, oil wells, gas processing plants, and refineries.

Swagelok

Swagelok is a manufacturer of duplex flanges. Swagelok offers a wide range of duplex flanges in different sizes and materials.

Parker

Parker Hannifin is a leading manufacturer of duplex flanges. Parker’s duplex flanges are available in stainless steel, brass, and aluminum.

Flowserve

Flowserve is a leading manufacturer of duplex flanges. Flowserve’s duplex flanges are available in stainless steel, carbon steel, and alloy steel.

Neway Valve

Neway Valve is a leading manufacturer of duplex flanges. Neway’s duplex flanges are available in stainless steel, alloy steel, and titanium.

Metraflex

Metraflex is a leading manufacturer of duplex flanges. Metraflex’s duplex flanges are available in stainless steel, carbon steel, and alloy steel.

The use of duplex socket welding flange can help to reduce the amount of time required to install a pipe.

Duplex steel 2205 flange is available in a wide range of sizes and materials, so you can find the right duplex flange for your application.

When selecting duplex flanges manufacturer, make sure to consider the type of material, size, and pressure rating.

The manufacturing companies listed above offer a wide range of duplex flanges to choose from. So, if you’re looking for a quality duplex flange, be sure to check out the manufacturers listed above.

9. Cost of Duplex Flange

The cost of a duplex flange can vary depending on the size and type you need. However, on average, it can range from US$10 to US$200.

Generally, duplex flanges are more expensive than stainless steel flanges because they are made of higher-quality material. However, the price also depends on the supplier.

To know more about how flanges are produced, watch this video.

10. Conclusion

Duplex flanges are a versatile and handy tool that can be used in a variety of industries.

If you’re looking for a quality duplex flange, or need help selecting the right one for your needs, contact us today at Oflange.

We have years of experience helping businesses find the perfect flanges for their applications.