PRODUCT FEATURES

DIN Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

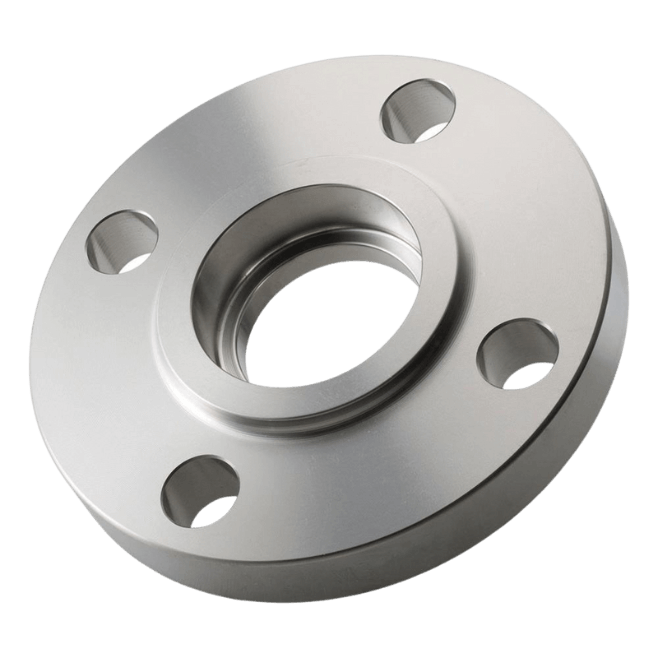

DIN Flange

The DIN Flange is a standard size that fits most valves. It is easily assembled and disassembled for repair or replacement.

The DIN flange valve has been designed to withstand high pressures and temperatures, making it ideal for industrial applications. It can be used in a variety of industries including water treatment plants, food processing facilities, chemical plants and power generation stations.

The DIN flange valve comes with a 3/8 inch male NPT threading that connects to the pipe or hose line. This product is made of 304 stainless steel and is very sturdy. This product comes in a variety of sizes to best suit your needs.

Table of contents

1. DIN Flange Definition

What is DIN flange? DIN stands for “Deutsches Institut für Normung”, a national organization for standardization in Germany.

It is a standard flange in the shape of a flat ring, with a raised face, used for joining pipes. DIN pipe flanges are the most common type of flanges in use today. They are usually made from cast iron or forged steel alloy. DIN flange is a type of flange that’s commonly used in Europe and Japan.

DIN flange specifications are as follows: the DIN flange has a bore diameter of D, a thickness of t, a height of h, and a width of w. The DIN flange is also drilled with six holes that have a diameter of d. DIN flange of D = 32mm, t = 1.25mm, h = 8.8mm, w = 51mm, d = 16mm.

2. Most Common Uses for DIN Flange

The following are some of the most common uses of DIN flange:

- DIN flange is often used for joining pipes and tubes.

- DIN flange is also used in the manufacture of tanks, drums, and other pressure vessels.

- DIN flange can be used as a closure in piping systems.

- DIN flange can also be used as a vent or drain in piping systems.

- DIN flange is used as a connection point for hoses and tubing.

- DIN flange can also be used as a mounting flange.

3. Identifying a DIN Flange

There are a few key features that you can look for to identify a DIN flange:

DIN Symbol

DIN symbols can include numbers ranging from DIN 1 to DIN 1624, etc. DIN 1 is the smallest DIN flange, while DIN 1624 is the largest DIN flange available.

Dimensions of the Flange Embossed in

The dimensions of the flange will be embossed in the DIN symbol. These dimensions will include the diameter, thickness, and a number of holes in the flange.

Made From Stainless Steel or Carbon Steel

DIN flange is available in both stainless steel and carbon steel. The type of material will be embossed in the DIN symbol.

Raised Face

The DIN flange will have a raised face that is perpendicular to the bore of the flange. This raised face is used for welding or bolting the flange to another object.

Threaded Hole in the Center

The DIN flange will have a threaded hole in the center that is used for attaching the flange to another object. This threaded hole is also known as the tapped hole.

4. Various Types of DIN Flange and Their Features

Here are the different types of DIN flange and their features:

| Flat Ring Flanges | DIN 2501 flat ring flange is the DIN standard for welding neck, slip-on and blind flanges for low pressure service up to 16 bar (PN 16/25). |

| Alternate Face Flanges | DIN alternate face flange is a versatile type of DIN flange that allows for the joining of pipes to any DIN fitting. It is also available in welding neck, slip-on and blind type. |

| Weld Neck Flanges | DIN weld neck flange is the DIN standard for welding neck, slip-on and blind flanges when pressure requirements are high. They also come in different sizes ranging from DIN 25 to DIN 2500 with working pressures of up to 400 bar (PN 400 /16). |

| Lap Joint Flanges | DIN lap joint flange is DIN standard for welding neck, slip-on and blind flanges for medium to high-pressure services (PN 16/25 up to PN 40/200) with working pressures between 16 bar to 400 bar. |

| Ring Type Joint Flanges | DIN ring type joint flange is DIN standard for welding neck, slip-on and blind flanges for low-pressure services up to 16 bar (PN 16/25). A DIN ring type joint flange can come in different forms. |

| Threaded/Companion Flanges | DIN threaded/companion flange is DIN standard for welding neck, slip-on and blind flanges designed to join pipes or install fittings in piping systems. They are available in sizes ranging from DIN 110 to DIN 2500 with working pressure of up to 400 bar (PN 40/200). |

| Blind Flanges | DIN blind flange is DIN standard for welding neck, slip-on and blind flanges designed to fit on the outside of a pipe. They are available in sizes ranging from DIN 25 to DIN 2500 with working pressure between 16 bar to 400 bar (PN 16/25 up to PN 40/200). |

5. Process of Installing DIN Flange on a Pipe or Tube

Here is a step by step guide to installing DIN flange on a pipe or tube.

Step #1 Determining DIN Flange Size

The DIN flanges are available in various sizes, so it is necessary to determine the size before installation. There are several ways to find out DIN flange sizes.

DIN flange size can be determined by measuring the outside diameter of the pipe using a caliper or taking measurements from din flange dimensions given in DIN standards.

Step #2 Getting the DIN Flange Ready for Installation

The DIN flanges should be prepared for installation before hand. This includes cleaning the DIN flange to remove dust, oil or dirt deposits. DIN flanges should also be inspected for any damage that will prevent the DIN flange from being used.

Step #3 Preparing DIN Flange for Installation

While DIN flanges are normally made in standard sizes, usually DIN 2501 or DIN 2566, they may require modifications to fit the needs of the pipe. If there is a large difference between DIN flange size and DIN STD, DIN flange should be customised before installation.

Step #4 Installing DIN Flange on Pipe or Tube

DIN flanges are installed by tightening bolts with a torque of at least 1/5 Nm per bolt. If there are 4 bolts, this means that the minimum torque is 20 Nm. DIN flange is installed with DIN 2501 bolts.

Step #5 DIN Flange Inspection

DIN flange should be inspected after installation. DIN EN 1092-1 recommends that DIN flanges used for slip on or welding neck flanges should always be completely and securely tightened and checked for tightness and cracks before the DIN flange is ready to use.

6. Advantages of Using DIN Flange

Here are the advantages of using a DIN flange.

Corrosion-Resistant

DIN flanges and fittings are manufactured from stainless steel din flanges and other corrosion-resistant metals which can resist corrosion up to 1,000°C. DIN flanges are more resistant to corrosion than Direct Steel-Arc Welding (DSAW) pipe.

Good Machining Properties

DIN flange fittings have good machining properties as they can be made from one piece of material. DIN flanges also have a better dimensional accuracy compared to DSAW pipe.

Greater Range of Sizes

DIN flanges have a greater range of sizes available when compared to DSAW pipe. This allows DIN flanges and fittings to cater for diverse applications, such as high or low pressures, and large or small diameters. DIN flange size CN6 is the DIN standard flange size commonly found in automobile exhaust systems.

High Pressure

DIN flanges are capable of withstanding high pressures up to 1,500 bar. The DIN flange pressure and temperature ratings and should meet or exceed the operating pressure of your application.

7. Disadvantages of Using DIN Flange

Here are the disadvantages of using DIN flanges:

Difficult and Expensive to Fabricate

DIN flanges are difficult and expensive to fabricate as DIN flanges need to be manufactured from one piece of material.

Expensive to Handle

DIN flanges, as well as DIN flange fittings, are expensive to handle due to their corrosion-resistant properties. DIN flanges are not recyclable. DIN flanges also have a higher weight per unit of volume compared with DSAW pipe.

8. Common DIN Flange Problems and the Best Way to Avoid Them

Here are the common DIN flange problems and how to avoid them.

Too Thick or Too Thin

DIN flanges dimensions in mm are supposed to be exactly 2mm thick. If your DIN flange is either too thick or too thin, it has not been cut correctly. Best way to avoid this is by applying tape to the DIN flange before cutting it.

Misaligned DIN Flange Connection

A DIN flange is supposed to be centered on the connector, not off to one side or another. If your DIN flange is misaligned, you may have cut the flange at an angle. To avoid this, cut flanges on a cutting guide instead of freehanding it.

Lack of Parallelism

Parallelism is critical for DIN flange interference fit with plugs and bushings. If your flange is not parallel, it will leak. The best way to avoid this is by assembling DIN flanges on a flange jig.

Warped DIN Flanges

Warped DIN flanges have curved sides rather than straight sides. DIN flange is supposed to be perfectly flat, so if your flange din is warped it has been cut incorrectly or manufactured incorrectly. Be sure to use DIN flange sheets that are already parallel.

9. Average Cost of DIN Flange

Generally, a DIN flange costs around USD 25 to USD 50.

Cost is determined by size and manufacturer. The larger DIN flange is, the more expensive it will be. DIN flanges manufactured by large-scale companies such as Oflange tend to be less costly than DIN flanges made by small, lesser-known companies.

10. 5 Tips to Select the Right DIN Flange Dimensions for Your Needs

Here are the tips on how to select the right DIN flanges dimensions for your needs.

#1 Determine DIN Flange Dimensional Form

The DIN flanges are available in different dimensional forms, including DIN 2527, DIN 2566, DIN 2573, DIN 2641 and DIN 2631. Each of these configurations is uniquely designed for specific applications or mounting style.

#2 Determine the Installation Type

You need to determine the installation type. DIN flange is available in different style, size and mounting design that are used for different applications.

#3 Identifying the Material

Moreover, you need to identify the material of your flanges that are predominantly available in carbon steel din flange and stainless steel din flange. Also, make sure that the din flange bolt sizes and lengths are compatible with DIN flange materials.

#4 Determining DIN Diameter

As DIN flange is available in different diameter, you need to identify the DIN size that meets your requisites.

#5 Determining the Material Thickness of DIN Flanges

You also need to determine the thickness of DIN flange material as it varies depending on the DIN Diameter. DIN flange is available in different thickness, including 0.60mm; 0.80mm; 1.00mm; 1.20mm; 1.50mm; 1.60mm; 1.80mm, 2.00mm and others.

11. 4 Tips for Maintaining DIN Flange

Here are few tips on how to maintain DIN flange.

#1 Tighten Screws and Bolts

Ensure that all the screws and bolts are tightened while mounting a flange to its application. Avoid using lubricating oil to reduce corrosion risk. In case, you notice any leakage in the seal area, tighten the fixtures or contact your service provider for assistance.

#2 Avoid Harsh Conditions

DIN flanges in the applications where there are chances of rough vibration or sudden shock, so that it can absorb some shocks. Moreover, you need to avoid any harsh conditions for the flange. Avoid exposing your equipment to extreme weather conditions.

#3 Keep it in a Cool and Dry Place

DIN flanges are sensitive equipment, so you need to keep them in a cool and dry place. Drenching flange or any other components from time to time can damage the material. DIN flange can be exposed to extreme temperatures; so you need to ensure that your equipment is cool and dry.

#4 Avoid Any Contact With Corrosive Material

DIN flanges in the presence of corrosive chemicals, so you need to keep your equipment away from any contact with these materials. These corrosion-resistant components reduce the chance of a chemical attack on your system.

If you want to know the production process of flange, check out this video.

12. Conclusion

If you’re looking for a versatile and reliable component for your next project, DIN flanges are a great option. With multiple size and thickness options, as well as different diameters to choose from, you’re sure to find the perfect fit for your needs.

Contact us at Oflange today if you need assistance finding the right DIN flange or any other component for your next project. We’d be happy to help!