PRODUCT FEATURES

DIN 2576 Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

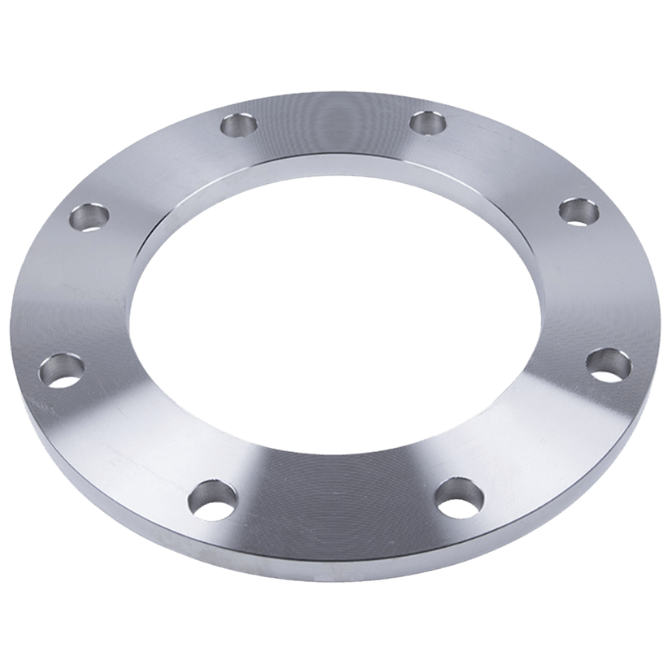

DIN 2576 Flange

Are you looking for a reliable and efficient way to connect piping? If so, you should consider using DIN 2576 flanges.

The DIN 2576 Flange is a type of flange that has been designed to be used in the construction of machinery and piping.

It features extremely strong construction, making it suitable for use with high-pressure applications. The material used to manufacture this product is corrosion-resistant, ensuring its long-lasting performance.

Keep reading to learn more!

Table of contents

1. DIN 2576 Flange Definition and its History

A DIN 2576 Flange is a type of flange that is specified in DIN 2576. It is a circular flange with a raised face. The flange is used to connect pipes or tubes.

DIN means Deutsches Institut für Normungn or German Institute for Standardisation, in English. DIN publishes specifications and dimension standards that apply to Germany. This includes:

- Welding neck flanges

- Threaded flanges

- Hex flanges

- DIN 2576 PN10 flange

DIN 2576 was first published in 1977 and has since been revised several times with the latest revision (the fourth) being issued in 1997.

A DIN 2576 Flange can be either loose or tight. A DIN 2576 loose flange has a gasket (more commonly known as an o-ring) in between the raised face and the outside of the pipe.

This type of flange does not create pressure on the pipe, but rather it seals around it to maintain a watertight connection.

A DIN 2576 tight flange uses bolts to clamp the raised face onto the outside of the pipe. This type of connection provides pressure on the pipe, ensuring that it remains watertight.

DIN Flanges is used around the world to connect pipes in plumbing systems and is very common in Germany due to DIN’s popularity.

If you want to learn more about DIN 2576 dimensions, specifications, and other types of flanges, and how they can help your piping business, feel free to contact us at Oflange.

2. The Difference Between DIN 2576 Flange and Other Flange

DIN 2576 flange is a type of flange that is specifically designed for use in piping and tubing systems.

| Smaller Diameter | It has a smaller diameter than other flanges. Thanks to its’ smaller pipe flange dimension nuts which allow it to be used in narrower spaces. Other flanges, such as ASME flange and UNI flange, have a larger diameter than DIN 2576 flange. This means that they cannot be used in narrower spaces. |

| Easier to Install and Remove | DIN 2576 flanges are also easier to install and remove than other types of flanges, hot-dip galvanized DIN 2576 PN10 plate flange does not require specialized tools. |

| Can Be Used in Different Applications | DIN 2576 flanges can be used in applications ranging from petroleum, chemical processing, and power generation to wastewater treatment. |

| High Pressure Rating | DIN 2576 flanges have a high pressure rating, making them ideal for use in high-pressure applications. While other flanges may have a higher pressure rating than DIN 2576, they are not as adaptable to different applications. |

3. DIN 2576 Flange Materials

Flange Materials are typically made from carbon steel DIN 2576, stainless steel, zinc plated, or other metals.

DIN 2576 is very specific about the flange materials used. DIN 2576 specifies a 2.5-meter drop test, which simulates a large mass falling from a height of 2.5 meters onto the flanges.

DIN 2576 specifies what type of material should be used for each type of application and even specify different metals for each DIN 2576 flange size.

DIN 2576 also requires that all DIN 2576 flange dimensions are checked during testing and throughout the manufacturing process, as well as a Rockwell hardness test every year.

4. DIN 2576 Flange Dimension

DIN 2576 is a German standard that specifies the dimensions of flanges. The standard is used to ensure that flanges from different manufacturers will be compatible with each other.

This usually includes a third-party inspection report that takes into account the flanges manufactured while comparing them to other DIN flange material test certificates such as pressure rating ANSI class for ASME flanges.

The standard covers flanges with a bore diameter of up to 400 mm and a thickness of up to 16 mm.

The DIN 2576 flange has several different dimensions, but its height is always 3/4 inches and the DIN 2576 flange outer diameter is 1-1/4 inches.

DIN 2576 specifies sizes for the flange faces, the bolt circle, the position of the holes about the flange plane, and several other dimensions that are required for interchangeability.

DIN 2576 also specifies tolerances on many of these dimensions. DIN 2576 is an international standard under ISO 10423.

5. DIN 2576 Flange Manufacturing Process

The DIN 2576 flange is a type of pipe flange that is commonly used in Europe. The DIN 2576 flange can connect two pieces of tubing due to the raised lip that surrounds the DIN 2576 flange hole in the center.

It is manufactured using the following process:

Step#1 Create a Blank

The first step is to create the flange blank. This is a piece of steel that has the desired shape and size of the flange. It is typically made by rolling or extrusion.

Step#2 Cut the Blank to Size

Next, the blank is cut to size and drilled to create the holes that will be used for the bolts. In addition to using a drill to cut a blank to size, a sand blasting machine is sometimes used to ensure a smoother surface for the flanges to cling on.

Step#3 Forge the Flange to its Final Shape

The next step is to forge or roll the flange to its final shape. The profile of the flange is then created by removing the excess material. This step can be done using a press or hammer.

Step#4 Heat Treatment

Once the flange is shaped, it is heat-treated to make it more durable. Temperatures for the heat treatment vary with the material used. For example, flanges made with carbon steel or nickel alloy are treated to a temperature of up to 500 degrees Celsius for 3 hours.

On the other hand, a DIN 2576 slip-on flange made from alloy steel and material tin bronze will be heat treated to a temperature of no less than 750 degrees Celsius for 3 hours.

Anti-rust paint such as a yellow transparent may be added to the nominal pipe size diameter to increase the material yield point corrosion resistance.

Step#5 Plating Process

The last stage of DIN 2576 flange manufacturing is the plating process, which can be done using various metals including stainless steel and chromium plating.

6. The Benefits of Using DIN 2576 Flange

The DIN 2576 flange is a type of flange that is commonly used in the piping industry. It offers many benefits, including:

Strength

The DIN 2576 flange is stronger and more durable than other flange types, and it can handle higher pressures and temperatures.

This type of flange is made to DIN standards, which means that it is manufactured to a high quality and will provide a reliable connection.

Ease of Installation

When it comes to ease of installation, DIN 2576 flange fittings are some of the easiest to install.

Their design allows for a quick and easy connection, with no need for tools or special equipment. In addition, their lightweight construction makes them easy to handle and transport.

Versatility

The DIN 2576 flange can be used with a variety of materials, including metal, plastic, and rubber.

Additionally, DIN 2576 flanges are available in a variety of sizes and shapes to suit your needs.

DIN 2576 flanges typically take less time to design and manufacture than other types of flat flange DIN.

Adaptability

DIN 2576 flanges are commonly used as a connecting flange for industrial pipes. These flanges make it easy for the piping system to withstand high pressure and stress.

It also allows for a snug fit that is free from leakage. The flange adaptability is a great way to ensure the quality of the connection, by ensuring quality sealing regardless of the situation.

Cost-effective

When it comes to choosing the right pushing machine flange for your needs, DIN 2576 is a great option.

Additionally, DIN 2576 flanges are typically less expensive than other types of flanges, making them a cost-effective option for covering bolt holes.

7. DIN 2576 Flange Application Industries

The DIN 2576 flange is a versatile product that can be used in a variety of industries.

This flange combined with an electric bevelling machine is a sturdy and reliable solution for a number of these types of applications, especially when the DIN 2576 flange is manufactured from stainless steel material.

Some of the most common applications for the DIN 2576 flange include:

- Piping and Plumbing

- Heating and Cooling

- Petrochemical

- Food and Beverage

- Pharmaceuticals

- Chemicals

- Heavy Oil Refineries

- Aerospace

- Shipbuilding

- Solar Power Plants

- Automotives

- X-ray Detectors

DIN 2576 flanges are the most popular in the petrochemical industry, with the majority of the oil extraction’s hydrostatic testing machine coming equipped with the DIN 2576 flange.

8. DIN 2576 Flange Average Cost

The average starting cost for a DIN 2576 flange is around US$27. Additional costs may be incurred depending on the add-ons that will be purchased, including die steel bending machine, duplex steel flanges bolts, oil black paint coating.

9. 4 Maintenance Tips for DIN 2576 Flange

There are several key maintenance tips for DIN 2576 flange that should be followed to ensure optimal performance and durability.

#1 Keep the Flange and Bolts Clean

It is important to keep the flange and bolts clean to prevent corrosion and ensure a tight seal.

The flange and bolts should be cleaned regularly with a solvent such as acetone or benzene. This will help remove any oil or grease that may have built upon the surfaces.

It is also important to check the gasket for damage or wear and replace it if necessary. A damaged gasket can cause a lot of problems, ranging from leaks and malfunctions to workplace injuries.

#2 Check the Tightness Regularly

It is important to check the bolts and nuts regularly to make sure they are properly tightened. If they are not tightened correctly, it can cause the flange to leak or become damaged.

#3 Look Out for Signs of Wear or Damage

It is important to regularly inspect the gasket for any signs of wear or damage. If the gasket is worn or damaged, it will need to be replaced to prevent leaks.

#4 Always Use the Correct Bolts and Washers

Make sure that you always use the correct bolts and washers when installing the flange. If you use the wrong bolts, it can cause damage to the flange and may lead to leaks.

10. Conclusion

Look no further than the DIN 2576 flange. This product has been designed to be extremely strong and corrosion-resistant, making it perfect for high-pressure applications.

With its durable construction and corrosion-resistant material, the DIN 2576 flange is perfect for anyone looking for a reliable way to connect piping.

Order yours today at Oflange!