PRODUCT FEATURES

Blank Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

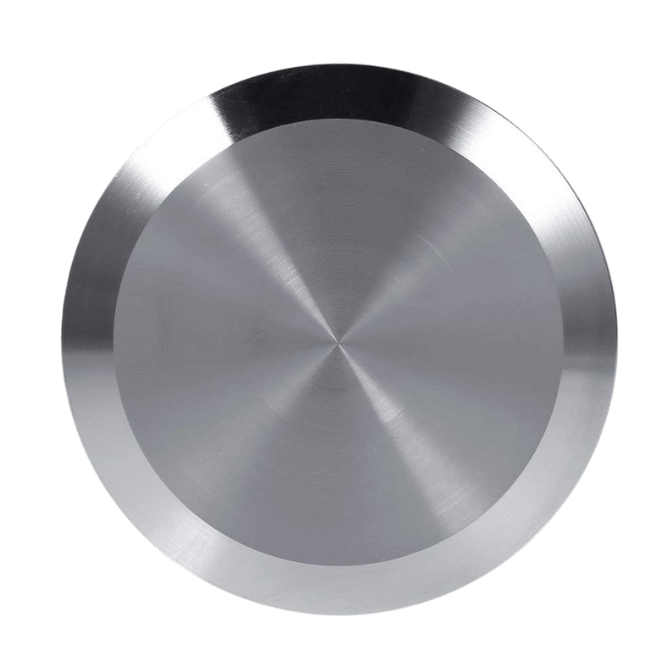

Blank Flange

Blank flanges are used in pipelines to blank off or close the end of a pipeline. They are also used as a mating surface for welding two pipes together. Blank flanges are available in several different sizes and materials.

They are typically made from carbon steel, stainless steel, or alloy steel. They can also be made from other materials such as titanium, nickel, and Hastelloy. Blank flanges are typically threaded or socket welded.

Table of contents

1. How To Identify a Blank Flange

When you’re working with piping and other industrial equipment, you may come across blank flanges for a pipe schedule. These are used to seal off an opening in a pipeline or other piece of equipment, and they can be identified by their smooth, unadorned surfaces.

Since a pipe blank flange doesn’t have any bolt holes or other features, it can be difficult to determine its size and other specifications.

Here’s how to identify a blank flange:

The Blank Pipe Flange Will Have a Smooth Surface

You can identify a blank flange by its smooth, unadorned surface. There will be no bolt holes or other features on the flange.

The Size of the Flange Will Be Unknown

Since a blank flange doesn’t have any bolt holes or other features, you won’t be able to determine the size of the flange without some special equipment.

The Blank Pipe Flange Will Not Have Any Bolt Holes

One of the key identifying features of a blank flange is that it will not have any bolt holes. This is in contrast to other types of flanges which do have bolt holes.

If you are unsure of the size or other specifications, you can contact us Oflange for more information. Our experts will be happy to help.

2. Blank Flange Cost

When it comes to blank flange cost, there are a few things to consider. The most important factor is the type of blank flange you need. There are several different types, and each one has its own unique set of specifications.

The average cost of a blank flange ranges from $50 to $300, depending on the type and size of the flange. However, it’s important to note that this is just a general estimate. The cost could be higher or lower depending on the specific needs of your project.

The cost of the blank off flange will also vary depending on the size and thickness of the metal. Make sure you have a good idea of what you need before you start shopping around for prices.

If you want an exact quote, it’s best to contact us at Oflange directly. We can help you choose the right flange for your needs and give you an accurate estimate of the cost.

3. Blank Flange Applications

A blank flange is a type of flange that does not have any holes. It is primarily designed to cover or blank off valves or a pipe connection. The stainless steel blank flange is often used in pipelines to prevent the flow of material from one section of the line to another.

They can also be used as a seal between two sections of pipe. Blank flanges are made from a variety of materials, including carbon steel, stainless steel, and aluminum.

Some of the applications that blank flanges are used in include:

Pipeline Connections

Blank flanges are often used in pipelines to prevent the flow of material from one section of the line to another. It can also be used as a seal between two sections of pipe.

Medical Devices

Blank flanges are also used in medical devices to cover or blank off a pipe connection. This helps to keep the device clean and prevent any material from entering it.

Machinery Parts

In machinery, blank flanges are often used as spacers between two parts. This helps to ensure that there is proper alignment and prevents damage to the parts.

Pump Repairs

When repairing a pump, it is often necessary to blank off the inlet and outlet ports. This allows you to work on the pump without any material entering or leaving it.

Valve Repairs

Similarly, when repairing a valve, blank flanges can be used to cover the inlet and outlet ports. This will help to keep the valve clean and free from debris.

Instrumentation Connections

Instrumentation connections often use blank flanges to cover the connection points. This helps to keep the instrument clean and free from contamination.

Fitting Connections

Fitting connections are another place where blank flanges are often used. This helps to ensure that there is no leakage at the connection point and keeps the area clean.

As you can see, blank flanges have a variety of applications in a number of different industries. They are essential for ensuring that pipe connections stay clean and free from contamination.

4. Determining the Size of a Blank Flange

When it comes to blank flanges, determining the size is one of the most important steps in the process. There are a few different ways to go about doing this, and the method you choose will largely depend on the specific application you’re using the blank flange for.

Here’s how to determine the size of a blank flange:

Measuring the Inner Diameter

The first way to determine blank flange size is by measuring the inner diameter. This is probably the simplest method, and it’s also a good option if you already know the dimensions of the hole you’re trying to cover.

To measure the inner diameter, simply use a caliper or ruler to measure the width of the hole. Once you have this measurement, you can use a blank flange size chart to find the appropriate size for your application.

Measuring the Outer Diameter

Another way to determine blank flange size is by measuring the outer diameter. This is a good option if you need to cover a hole with a large diameter, or if you’re not sure what the inner diameter of the hole is.

To measure the outer diameter, use a ruler or caliper to measure the width of the hole from one edge to the other. Once you have this measurement, you can use a blank flange size chart to find the appropriate size for your application.

Note: When measuring the outer diameter, be sure to include any flanges or fittings that will be attached to the blank flange.

Measuring the Thickness

The third way to determine blank flange size is by measuring the thickness. This is a good option if you need to cover a hole with a large thickness, or if you’re not sure what the inner diameter of the hole is.

To measure the thickness, use a ruler or caliper to measure the distance from one edge of the hole to the other. Once you have this measurement, you can use a blank flange size chart to find the appropriate size for your application.

Note: When measuring the thickness, be sure to include any flanges or fittings that will be attached to the blank flange.

By following these methods, you should be able to determine the size of a blank flange for your specific application.

5. How Is a Blank Flange Installed

When it comes to blank flanges, most people have no idea how they are installed. The truth is that there isn’t a specific way to install them – it all depends on the situation. That being said, here are some general guidelines for installing a blank flange:

Measure the Thickness of the Pipe and Then Subtract the Width of the Flange

The first step is to measure the thickness of the pipe. This can be done by using a ruler or caliper to measure the distance from one edge of the hole to the other. Once you have this measurement, you need to subtract the width of the flange.

You Have the Hole Drilled

The second step is to have the hole drilled. This can be done by using a drill bit that is the same size as the blank flange. Once you have the hole drilled, you need to clean up any debris that may be present.

Install the Blank Flange

The third and final step is to install the blank flange. This can be done by attaching the flange to the pipe using bolts, screws, or welds. Once the blank flange is installed, you need to make sure that it is properly aligned and level.

If you follow these guidelines, you should be able to install a blank flange without any problems. Just make sure that you measure the thickness of the pipe correctly and that you use a sealant that is compatible with your material.

If you’re looking for a blank flange, make sure to check out our selection at Oflange today. We have a variety of sizes and styles to choose from, so you’re sure to find the perfect one for your needs.

6. Potential Problems That Can Occur During or After Installation

When you’re installing a blank flange, there are several potential problems that can occur. Here are 5 of the most common:

Doesn’t Fit Properly on the Pipe

This is probably the most common issue with blank flanges. If the blank flange doesn’t fit properly on the pipe, it can cause all sorts of problems during installation and after. Leaks, for example, can be difficult to fix if there’s a misalignment between the blank flange and the pipe.

Isn’t Secured Correctly to the Pipe

If the blank flange isn’t secured correctly to the pipe, it can easily come loose. This can cause all sorts of problems, from leaks to complete system failure.

The Gasket Isn’t Seated Properly

If the gasket isn’t seated properly, it can cause all sorts of problems. Leaks are the most common issue, but the gasket can also fall out completely if it’s not secured correctly.

The Bolts Aren’t Tight Enough

If the bolts aren’t tight enough, the blank flange can easily come loose. This can cause all sorts of problems, as mentioned above.

The Blank Flange Is Damaged in Some Way

If the blank flange is damaged in some way, it can cause all sorts of problems. Leaks are the most common issue, but the blank flange could also break completely if it’s not made from a durable material.

If you’re aware of these potential problems and take steps to avoid them, your blank flange installation should go smoothly. However, if something does go wrong, be sure to contact a professional for help.

7. Blind Flange Specifications

A blind flange is a blank flange that does not have any holes. This type of flange is used to cover or close the end of a pipe. It is also used to join two pipes together. Blind flanges are made from various materials, including steel, stainless steel, and aluminum.

They come in a variety of sizes, and they are typically rated to hold a certain amount of pressure. There are several specifications that you need to consider when choosing a blind flange:

Size of the Flange

Blind flange sizes are typically given in inches. You need to choose a size that is compatible with the pipe you are using.

Type of Material

Blind flanges are made from a variety of materials, including steel, stainless steel, and aluminum. You need to choose a material that is compatible with the environment where the flange will be used.

Threading (If Applicable)

Some ductile iron blank flange has threaded ends, while others do not. If you need a threaded end, make sure to choose a blind flange that has the appropriate threading.

Pressure Rating

Blind flanges are rated to hold a certain amount of pressure. You need to choose a rating that is compatible with the environment where the flange will be used.

You will also need to consider the environment in which the blind flange will be used. For example, if you are using a blind flange in an extreme environment, you will need to choose a material that is compatible with that environment.

8. Blank Flange vs Blind Flange

Blank flanges and blind flanges are both types of flanges, but they serve different purposes. A blank flange is a plain flange that is machined but has no holes drilled in it. A blind flange is a type of blank flange that has one or more holes drilled in it, making it a functional flange.

There are several differences between blank flanges and blind flanges. Below are some of the most important differences:

| Blank Flange | Blind Flange |

|---|---|

| used to close off the end of a pipe or tubing system | used to connect two pipes or tubes together |

| blank flanges are machined | blind flanges are drilled |

| have no holes drilled in them | have one or more holes drilled in them |

If you are unsure which type of flange you need, consult with a qualified engineer. Flanges can be confusing, but they are an important part of any piping or tubing system. Make sure you select the right flange for your application to ensure a successful installation.

9. Types of Blank Flange

There are a few different types of the blank flange that are available on the market. Below are the common types that you will find:

Slip-On Flange

This type of blank flange is the most common and it is easy to install. It has a lip on the end that slips over the pipe and then gets welded in place.

Weldneck Flange

This type of blank flange is more difficult to install, but it is very strong. The neck of the weld neck flange extends beyond the pipe and gets welded to the pipe.

Blind Flange

This type of blank flange is used when you need to close off a section of piping. It has no opening and therefore does not allow fluid to flow through it.

Lap Joint Flange

This type of blank flange is similar to the slip-on flange, but it has a lap joint that allows it to be attached to two pipes. It is not as strong as the weld neck flange or the blind flange, but it is easier to install.

Socket Weld Flange

This type of blank flange is similar to the weld neck flange, but the neck is not as long. It gets attached to the pipe with a socket weld.

Threaded Flange

This type of blank flange has threads on the outside that allow it to be screwed onto a pipe. It is not as strong as the other types of blank flanges, but it is easy to install and remove.

Which type of blank flange is best for your project will depend on a few factors, such as the strength required and the ease of installation. Talk to a professional at your local hardware store to help you decide which type is best for you.

10. Final Words

Blank flanges are the perfect solution. They can be used to close off or blank the end of a pipeline, or as a mating surface for welding two pipes together.

You can trust our products to get the job done right. We have years of experience manufacturing and supplying blank flanges to customers all over the world. Contact us at Oflange today to learn more about our blank flanges!