PRODUCT FEATURES

ASTM Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

ASTM Flange: An Overview

If you’re in the business of manufacturing or supplying piping systems, then you’re likely familiar with ASTM flanges. But what are they? And more importantly, how can they help your business?

ASTM flanges are a specific type of flange that is used in a variety of industries. They can be made from different materials, and come in a variety of sizes.

In this post, we’ll answer all those questions and more. So, if you’re curious about ASTM flanges, read on!

Table of contents

1. ASTM Flange Specifications

ASTM flange specifications define the dimensional requirements for flanges made from different stainless steel materials. They also include requirements for gaskets, bolts, and nuts.

There are a variety of ASTM flange material specifications, each tailored to a specific material or application. Some of the most common ASTM flange specifications include:

| ASTM A105 | For carbon steel flange material |

| A350 | For alloy steel flange materials |

| B16.5 | For pipe flanges up to 24″ diameter |

| B16.47 | For large diameter pipe flanges |

| M SS SP44 | For stainless steel flanges |

| ASTM A350 LF2 | For low-pressure and high-temperature applications |

| ASTM A694 F42 | For high-pressure and high-temperature applications |

When selecting an ASTM flange specification, it’s important to consider the material and dimensions of the flange. You also need to make sure the specification is compliant with any applicable codes and standards.

2. ASTM Flange Standards

ASTM flange standards are important for ensuring that flanges manufactured to these specifications meet the required tolerances and dimensions. This facilitates the interchangeability of parts and minimizes the need for re-design and re-manufacturing of parts.

There are several different ASTM flange standards, each covering a range of flange sizes and ratings. Some of the more commonly used standards include:

ASTM A105

ASTM flange material A105 covers carbon steel flanges up to 900 psi.

ASTM A350

Covers carbon, nickel alloy grades, and stainless steel flanges for high-pressure and high-temperature applications.

ASTM A182

Covers alloy steel forged flanges for high-pressure and high-temperature applications.

ASTM A694

Covers carbon and alloy forged steel flanges for high-pressure pipeline components.

ASTM F1136

Covers low-temperature carbon steel, and extremely corrosion-resistant alloy ASTM flange standards up to 2500 lb nominal pressure.

Therefore, it is important to select the appropriate ASTM flange standard when specifying a flange. This will ensure that the parts are manufactured to the correct specifications and that they meet the required performance criteria.

3. ASTM Flange Applications

ASTM flanges are widely used in various industries. Some of the most common applications for ASTM flanges include:

Chemical Processing

Chemical processing is one of the most common applications for ASTM flanges. They are used to connect pipes and tubes in chemical plants and refineries. This allows liquids and gases to flow between different parts of the plant, making it a vital component of the manufacturing process.

Piping and Plumbing

ASTM flanges are also commonly used in piping and plumbing applications. They provide a strong and reliable connection point for water lines, gas lines, and other types of piping, and they can withstand the high pressure and temperatures that are often found in these environments.

HVAC Systems

ASTM flanges are often used in HVAC systems. They provide a strong and reliable connection point for heating, ventilation, and air conditioning equipment, and they can withstand the high pressure and temperatures that are often found in these environments.

Refining and Petrochemical

ASTM flanges are often used in refining and petrochemical applications. They provide a strong and durable connection point for piping and other equipment, and they can withstand the high pressure and temperatures that are often found in these environments.

Power Generation

ASTM flanges are also commonly used in power generation applications. They provide a strong and reliable connection point for turbines, generators, and other equipment, and they can withstand the high pressure and temperatures that are often found in these environments.

ASTM flanges are made from high-quality stainless steel flange materials and are designed to meet the rigorous demands of these industries. They provide a reliable seal and allow for easy assembly and disassembly.

4. Types of ASTM Flanges

ASTM flanges are one of the most popular types of flanges. They come in a variety of sizes and shapes and can be used in a variety of applications. Some of the most common types of ASTM flanges include:

Blind Flanges

Blind flanges are used to seal off a pipe or opening. They have a hole in the center that allows fluid to flow through, and they are typically used in conjunction with a gasket to create a seal.

Lap Joint Flanges

Lap joint flanges are used to connect two pipes. They have a groove on the face of the flange that allows them to be attached to two pipes, and they are typically used with a gasket to create a seal.

Socket Weld Flanges

Socket weld flanges are used to connect two pipes. They have a socket on the face of the flange that allows them to be attached to two pipes, and they are typically used with a gasket to create a seal.

Slip-on Flanges

Slip-on flanges are used to connect two pipes. They have a groove on the face of the flange that allows them to be attached to two pipes, and they are typically used without a gasket.

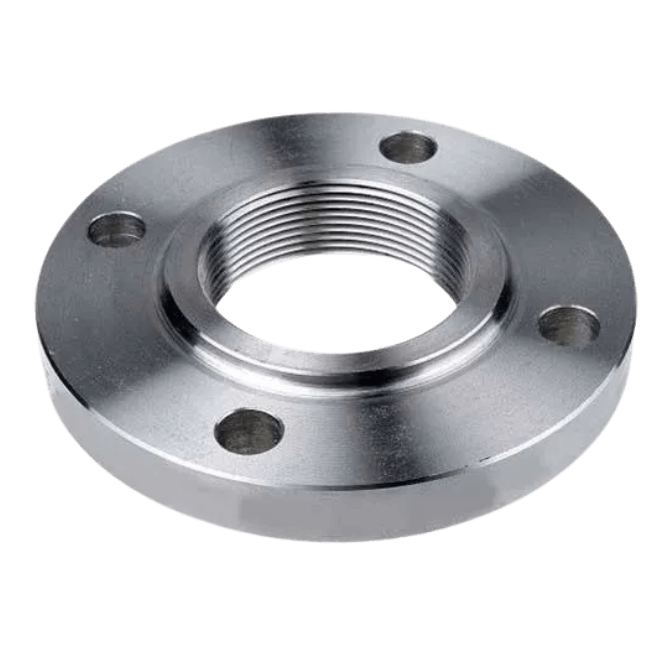

Threaded Flanges

Threaded flanges are used to connect two pipes. They have threads on the face of the flange that allow them to be attached to two pipes, and they are typically used with a gasket to create a seal.

Weld Neck Flanges

Weld neck flanges are a type of ASTM flange that is used to connect two pipes. They have a weld neck joint that allows them to be attached to two pipes, and they are typically used with a gasket to create a seal.

Reducing Flanges

Reducing flanges are a type of ASTM flange that is used to connect two pipes. They have a reducing joint that allows them to be attached to two pipes, and they are typically used with a gasket to create a seal.

Each type of ASTM flange serves a different purpose, but they all have one thing in common they are used to connect pipes and other mechanical components. For more information contact us at Oflange.

5. Benefits of Using an ASTM Flange

An ASTM flange is a machined part that is used to connect two or more pieces of pipe or tubing. Flanges are available in a variety of sizes and materials, including high yield carbon steel, stainless steel, and aluminum.

There are several benefits to using an ASTM flange:

Strong and Durable

Astm flanges are designed to withstand high pressure and stress, making them ideal for use in heavy-duty applications.

Easy To Install

It’s easy to install ASTM flanges because they can be bolted together without welding. This saves time and money when installing new equipment or repairing existing systems.

Cost-Effective

An ASTM flange is a low-cost, durable option for industrial applications. The parts come in various sizes so you don’t have to worry about having the perfect fit.

Leak-Proof

Flanges are designed for a tight seal, making them leak-proof and ideal for use in critical applications.

Corrosion-Resistant

Astm flanges are made from corrosion-resistant materials, making them ideal for use in harsh environments.

For these reasons, ASTM flanges are a popular choice for many industrial applications. If you need a strong, durable, and leak-proof connection, an ASTM flange is a perfect solution.

6. Selecting the Right Type of ASTM Flange for Your Needs

When selecting an ASTM flange, it’s important to choose the right type for your needs. There are a variety of types available, each with its own set of benefits and drawbacks.

Here are some things to consider when selecting an ASTM flange:

The Type of Material

The type of material is an important consideration when selecting an ASTM flange. Some materials are more durable than others, and some are more resistant to corrosion.

The Pressure Rating

The pressure rating is a major consideration when selecting an ASTM flange. You’ll want to select one that has a high enough pressure rating for your needs, but not so high that it’s difficult or expensive to manufacture the fitting.

The Type of Connection

The type of connection is an important consideration when selecting a flange. There are various types of connections, including threaded (NPT), welded (WFS), and slip-on (SOS). You’ll need to decide which one you prefer for your needs.

The Size of the Flange

The size of the flange is also an important consideration. You’ll need to select one that’s large enough to fit your needs, but not so large that it’s difficult or expensive to manufacture.

ASTM flange grade chart is a helpful resource for those who need to know more about ASTM flanges. It includes information on the grades of the ASTM flange and what they are used for. The chart also includes information on the materials used to make ASTM flanges, as well as the pressure ratings and sizes of ASTM flanges.

There are other considerations when selecting an ASTM flange, but those listed above are among the most important. By taking these factors into account, you’ll make sure that the ASTM flange you select is right for your needs.

7. How To Properly Install and Use an ASTM Flange

An ASTM flange is a type of flange that is used in the construction and manufacturing industries. It is important to install and use an ASTM flange properly to ensure its safety and longevity.

The following are steps on how to properly install and use an ASTM flange:

Step#1 Inspect the Flange

Before installing the ASTM flange, it is important to inspect it for any defects. If there are any defects, the flange should be fixed or replaced before use.

Step#2 Install the Flange

Once the flange is inspected and deemed safe for use, it can be installed. The flange should be installed on a flat surface and properly aligned. It is also important to make sure that the bolts are tight before using the flange.

Step#3 Tighten the Bolts

After installing the ASTM flange, it is important to tighten the bolts. The recommended torque should be used when tightening the bolts.

Step#4 Check for Leaks

Once the ASTM flange has been installed and tightened, it is important to check for any leaks. If there are any leaks, they should be fixed before using the flange.

Step#5 Use the Flange Safely

After installing and checking the ASTM flange, it is important to use it safely. The ASTM flange should not be used when there are any defects or leaks present. It is also important to avoid using the ASTM flange at high pressures or temperatures that exceed its rated capacity.

The ASTM flange should be properly installed and used to ensure its safety and longevity. It is important to follow the steps outlined above when installing an ASTM flange.

8. 3 Maintenance Tips for ASTM Flanges

ASTM flanges are an important part of many piping systems, and it is important to maintain them properly to ensure that they function properly and last a long time. Here are some tips for maintaining your ASTM flanges:

#1 Clean Them Regularly

It is important to clean your ASTM flanges regularly to prevent the buildup of dirt and other contaminants. Use a mild detergent and a soft brush to clean them, making sure to remove all debris.

#2 Inspect Them Periodically

Inspect your ASTM flanges periodically for damage or signs of wear. If you find any problems, repair them immediately.

#3 Lubricate Them as Needed

Lubricating your ASTM flanges is important to keep them functioning properly. Use a high-quality lubricant that is compatible with the metal of your ASTM flange. Apply it evenly and allow it to dry completely before using the ASTM flange again.

Following these tips will help ensure that your ASTM flange lasts a long time and functions properly.

9. Cost of ASTM Flanges

ASTM flanges are a common type of flange that is used in many industries. They are known for their high quality and durability. However, they can be expensive depending on the size and type of ASTM flange that is purchased.

ASTM flanges are not cheap, but they are worth the price. The cost of an ASTM flange can range from $50 to $500, depending on the size and type of flange. However, this is a small price to pay for the peace of mind that comes with knowing your equipment is up to spec.

If you’re looking for a quality, ASTM-compliant flange, be prepared to spend a bit of money. But, in the long run, it will be worth it.

Oflange has a large selection of ASTM flanges available, so be sure to check us out if you need one. We can also supply custom-made flanges to your specification. Please contact us at Oflange for more information or quotes on any product you need.

To know more about pipe flanges, watch this video.

10. Conclusion

ASTM flanges are a great choice for high-pressure applications. If you’re looking for a quality, reliable flange that will hold up under pressure an ASTM flange is the way to go. We carry a wide variety of ASTM flanges in stock and can help you find the perfect one for your needs.

If you need assistance finding the right ASTM flange or any other industrial supplies, don’t hesitate to call us at Oflange.