PRODUCT FEATURES

ASA Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

ASA Flange: A Comprehensive Guide

ASA flanges are a popular choice in the world of piping. But what are they? And why are they so popular?

ASA flanges are some of the most popular types of flanges used in business. They’re strong and durable, making them perfect for high-pressure applications.

In this guide, we’ll answer those questions and more. We’ll also provide a comprehensive overview of ASA flanges, including their specs, features, and benefits. By the end of this guide, you’ll know everything you need to know about ASA flanges! So let’s get started.

Table of contents

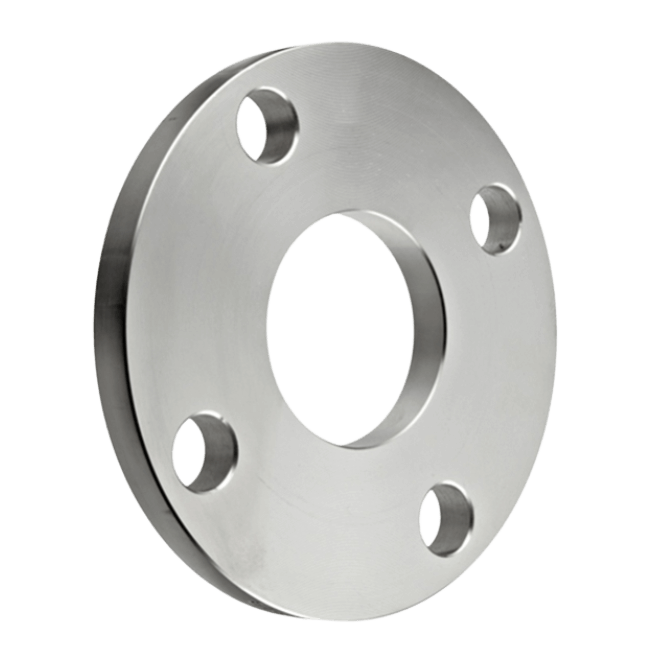

1. What Is an ASA Flange

An ASA flange is a type of flange that is made from aluminum and has an aluminum alloy body. It is a popular choice for high-pressure applications, thanks to its strength and durability. ASA flanges are available in a variety of sizes, and they have several features and benefits that make them a popular choice for businesses. It also comes in different class such as ASA 150 flange and ASA 300 flange.

ASA flanges are named for the American Standards Association, which standardized them in 1938. ASA flanges can also be referred to as ANSI flanges since they are based on a standard that was created by the American National Standards Institute (ANSI).

The most popular type of ASA vacuum flange is made from aluminum alloy 300. This material is strong andcorrosion-resistant, which makes it perfect for high-pressure applications.

2. Uses of ASA Flange

There are many different applications for ASA flanges. Some of the most common uses include:

Pipe Connections

Pipe connections are one of the most common uses for ASA flanges. The flange allows for a secure connection between two pipes, which can then be used to transport fluids or gases. This is a very common application in industries like construction and manufacturing.

Manifold Assemblies

A manifold assembly is a device that allows multiple pipes to be connected to a single source. This can be useful in applications where there is a need to regulate the flow of fluid or gas through multiple pipes.

Valve and Pump Attachments

When a valve or pump is attached to a pipe, it needs to be secured in place. This is often done using an ASA flange. This allows the valve or dry scroll vacuum pumps to be easily removed when needed, without having to disconnect the entire pipe.

Instrumentation Fittings

They are often used in conjunction with valves, pumps, and other instruments to allow for easy installation and removal. Additionally, they can help to protect the instruments from damage.

Therefore, we can say that there are many different uses for ASA vacuum flanges. They are used in a wide variety of applications, from fluid and gas transportation to instrumentation fittings.

3. How Do I Identify an ASA Flange

An ASA flange is a type of flange that is used in the piping and plumbing industries. It is important to be able to identify an ASA flange, as it is a common type of flange. Here are some ways to identify an ASA flange:

Look for the Letter “A” on the Flange

One way to identify an ASA flange is to look for the letter “A” on the flange. The letter “A” is stamped on the flange to indicate that it is an ASA flange.

Check To See if the Flange Has Three Holes

Another way to identify an ASA flange is to check to see if the flange has three holes. ASA flanges have three holes, while other types of flanges may have fewer or more holes.

Notice the Thickness of the Flange

The thickness of the ASA flange is another indication that you are dealing with an ASA flange. The wall thickness of an ASA flange will usually be between 0.15 inches and 0.25 inches thick, while other flange types may have a different wall thickness range.

Check the Size of the Flange

The size of the flange is another way to identify an ASA flange. For example, if you are looking for a specific size of an ASA flange, such as one that is 14 inches in width and 18 inches in height, then it will be easy to identify when compared to other types of flanges.

Look at Its Color

ASA flanges are also easy to identify by their color. ASA flanges are typically a light gray color, which makes them easily distinguishable from other types of flanges.

By using any of these methods, you should be able to determine whether or not you are dealing with an ASA flange. If you have any questions about identifying a specific type of flange, please contact Oflange for assistance.

4. Dimensions of an ASA Flange

An ASA flange is a type of flange that is used in the piping industry. It is made of aluminum and is designed to be used with a steel pipe.

The dimensions of an ASA flange are as follows:

| Flange Diameter | 4 inches |

| Flange Thickness | 0.25 inches |

| Bolt Circle Diameter | 5.125 inches |

| Number of Bolts | 8 |

The purpose of the dimensions is to make it compatible with standard pipe sizes and ASA fittings. The dimensions are also designed to provide a strong, reliable connection between the two components.

It is important to note that the hole size may vary depending on the application, and should be checked before the purchase.

5. ASA Flange Sizes

ASA flange sizes can vary greatly, depending on the application. In general, the sizes range from 1/2 inch to 24 inches. However, there are some exceptions. For instance, the largest ASA flange size is 36 inches.

ASA flange sizes are determined by the pipe size and the pressure rating. Generally, the pipe size will be a multiple of 2 inches. So, a 6-inch pipe will have an ASA flange size of 12 inches. The pressure rating will also affect the size of the ASA flange. A higher pressure rating will require a larger ASA flange.

ASA flanges are used in many industries. Some of the more common applications include oil and gas; power generation; water treatment; petrochemical processing; transportation infrastructure, etc. As you can see, there is no single application that requires ASA flange sizes to be specified to a particular size or pressure rating.

6. ASA Flange Standard

ASA Flange Standard is an American Society of Mechanical Engineers (ASME) standard that covers the design and manufacture of flanges made from wrought materials such as carbon steel, stainless steel, and alloys.

This standard is important because it helps ensure that flanges are manufactured to a high quality and are safe to use. The standard was first published in 1937 and has been updated many times since then.

ASA flange standard is one of the most widely used standards for welding pipe flanges and ASA fitting. It covers a wide range of applications, from low-pressure systems to high-pressure systems up to 15,000 psi (103 bar).

The standard also includes provisions for studding and bolting flanges together. The American Society of the Association (ASA) has developed a flange standard that is now commonly used in the United States.

This standard is known as ASA B16.5 and it covers various aspects of flanges, such as their dimensions, tolerances, and markings. Flanges that meet the ASA B16.5 standard are typically made from forged steel, although other materials may also be used.

To comply with the standard, flanges must meet certain dimensional requirements, including thickness, diameter, and hole spacing. They must also conform to certain tolerances about their size and shape.

Flanges that meet the ASA B16.5 standard are typically marked with the manufacturer’s name or logo, as well as the pressure rating for which they are designed. They may also include other information such as a material grade or certification mark.

7. ASA Flange Cost

When it comes to ASA flanges, there is no one-size-fits-all answer to the question of how much they cost. The price of an ASA flange can vary depending on several factors, such as the size and type of flange, the material it is made from, and the manufacturer.

That said, some general trends can give you a rough idea of what to expect. For smaller flanges (up to 24 inches), the cost is generally in the range of $50 to $150. Larger flanges tend to be more expensive, with prices ranging from $200 to $1,000 or more.

The most expensive ASA flanges are typically made from specialty materials such as titanium orInconel, while the cheapest flanges are often made from cast iron. It is important to keep in mind that these prices are just a general guideline.

For more information contact us at Oflange. Our experts will be happy to help you find the perfect ASA flange for your needs and budget.

8. 4 Tips on How to Maintenance and Care for ASA Flange

When caring for an ASA flange, it is important to keep in mind the following tips:

#1 Clean Regularly

It is important to keep the ASA flange clean. Any dirt, food, or moisture that has built up in and around it could cause permanent damage. You can use a cloth or a brush with soft bristles to clean the product.

Do not use any harsh chemicals like bleach as this could easily damage the material and reduce its life span.

#2 Lubricate Regularly

The flange should be lubricated regularly to ensure that it continues to function smoothly. You can use a silicone-based lubricant for this purpose. Do not use any kind of oil as this could damage the material over time.

#3 Inspect for Damage

It is important to inspect the ASA flange for any signs of damage regularly. If you notice any cracks, chips, or other damage, discontinue use and replace the product immediately.

#4 Inspect for Loose Parts

It is important to keep an eye out for any loose parts in the ASA flange. If you notice that the product has become too loose, it could lead to further damage and malfunctioning. You can use a bolt or screwdriver to tighten up these components as needed.

By following these tips, you can help ensure that your ASA flange lasts for many years.

9. Type of Bolts and Nuts Are Used With ASA Flange

There are many different types of bolts and nuts that can be used with an ASA flange. Here are some of the most common types:

Hex Bolts

These are the most common type of bolts, and they have a hexagonal head. They can be used with either a nut or a washer.

Socket Cap Screws

These bolts have a cylindrical head and are threaded to the end. They require a socket cap screwdriver to tighten them.

Set Screws

These are used to secure a component in place and have a pointed end and a threaded shaft. They don’t require a nut or washer.

Wing Nuts

These are easy to use and can be tightened by hand. They have two wings that grip the bolt when tightened.

Thumb Screws

These are similar to wing nuts, but they have a knurled head that can be turned with your fingers.

T-Nuts

These are used in conjunction with threaded rods or bolts. They have four prongs that grip the sides of the hole and prevent the bolt from rotating.

U-Bolts

These are used to secure pipes and have a curved shape with threaded ends. They require nuts to tighten them in place.

Eye Bolts

These are commonly used for mooring lines and have a looped end that can be attached to the anchor point or another line.

Lag Screws

These are used to anchor objects to a wooden surface and have a threaded shaft and a flat head.

Carriage Bolts

These have a square or hexagonal head that is designed to be countersunk into the material being bolted. The bolt has a smooth shank that runs through the hole in the material, and the end is threaded.

When choosing the type of bolt or nut to use with an ASA flange, you need to consider the application and what it will be used for. Make sure to use the correct type of bolt for the material that you’re bolting together, and use a nut that will fit properly.

There are many different types of bolts and nuts available, so take your time and choose the right ones for your project.

If you want to know how flanges are produced, check this video.

10. Conclusion

So there you have it, our comprehensive guide to ASA flanges. We hope you found this article helpful and informative. If you still have any questions or would like some advice on choosing the right flange for your project, please don’t hesitate to give us a call at Oflange. We’re always happy to help!