PRODUCT FEATURES

API Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

A Comprehensive Guide for API Flange

Flanges are an important part of many industrial and commercial applications. There are many different types of flanges, each with its specifications.

If you’re looking for a comprehensive guide on API flange dimensions and specifications, you’ve come to the right place.

In this article, we’ll discuss the different dimensions and specs of API flanges, as well as provide some tips on how to select the right flange for your needs. Stay tuned!

Table of contents

1. What Is an API Flange?

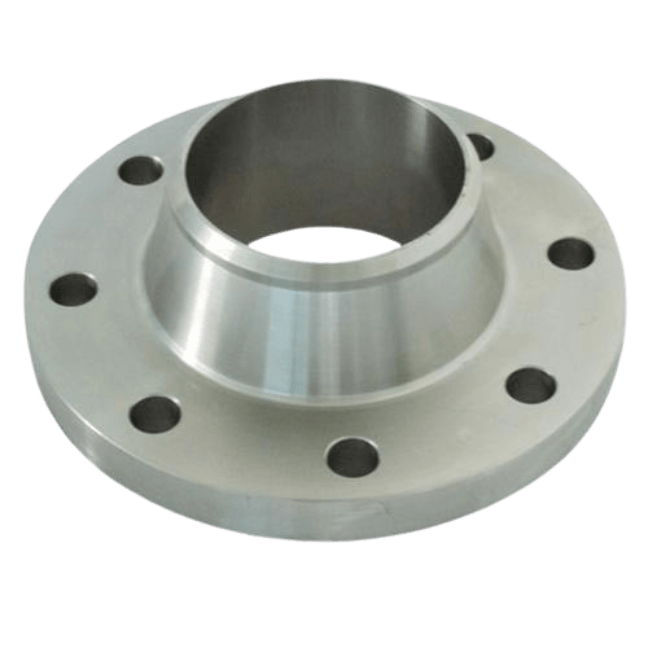

A flange is a type of fitting that is used to connect two pieces of pipe. It is a disk-shaped piece of metal that is bolted to the ends of the pipes. The flange provides a place for the bolts to secure the pipes together.

API flanges (American Petroleum Institute) are specifically designed for use with API pipes. These pipes are designed with very competitive lead times and API flange forgings to handle oil and explosive gases.

In API vs ANSI flanges, the full line API flange standard testing requirements are much more tolerant compared to the ANSI and Wellhead flange chart. So for the petroleum industry, ASME vs API, API flange dimensions are a clear choice.

They are made from higher quality steel than standard flanges and they have a greater tolerance for alignment error. This makes them ideal for use in oil and gas pipelines.

Connection

API flange pressure temperature ratings can be used in conjunction with the API flange bolt torque chart to create a stronger connection than using a standard API flange pressure rating.

This means that they are less likely to break or leak over time and will last longer than other types of pipes.

Tolerance

API flanges have a greater tolerance for alignment error so you don’t need to be as precise when connecting them to other API flange sizes. This makes them easier to use and reduces the chances of errors occurring during installation.

Resistance

The API flange material is made from higher quality steel than standard API flange pressure rating charts so they are more resistant to wear and tear. They will last longer under repeated use without corroding or breaking.

2. Uses of API Flange

API flange weights are used in a variety of applications across many industries. Some of the most common uses of API flange torque specs include:

- Petrochemical plants

- Pipelines

- Refineries

- Power plants

- Marine applications

API flange ratings are highly versatile and can be used in a variety of applications depending on the requirements of the project. They are often chosen for their high quality and performance, as well as their durability.

When it comes to choosing the right API flange specification for your project, be sure to consult with a reliable manufacturer who can help you find the best option for your needs. Contact us at Oflange for more details!

3. Different Types of API Flange

API flange is a type of API flange dimensions chart that is specifically used in the oil and gas industry. It is a standardized flange that has been developed by the American Petroleum Institute. There are several different types of API flange, which include:

Blind Flange

A blind flange is a type of flange that does not have a bore. This means that it does not have an opening through which fluid or other material can flow.

Instead, the blind flange is used to close off an opening in a pipeline or other system. It is installed by welding it into place, and then the weld is ground down so that the flange is flush with the surface around it.

Blind flanges are commonly used in pipelines and other systems where it is necessary to seal off an opening.

They are also used in conjunction with other flanges to create more complex assemblies. Blind flanges are made from a variety of materials, including steel, stainless steel, and aluminum.

Lap Joint Flange

Lap Joint Flanges are similar to Slip-on Flanges, except that they have a lap joint feature that allows them to be joined to another flange.

The lap joint is generally a male-female joint, where the male flange has a protrusion that snaps into the female flange. The lap joint flange is commonly used in pipelines and other industrial applications.

Socket Weld Flange

Socket weld flanges are used to join pipes together. The API flange bolt pattern is placed on the end of one pipe, and the other pipe is inserted into the hole in the center of the flange. A socket weld is then performed, which joins the two pipes together.

Threaded Flange

A threaded flange is a type of API flange ruler that has screw-like protrusions on the outside diameter of the flange.

This design allows for a more secure connection between two pieces of pipe, as the screws can tighten down to create a stronger seal.

These flanges are often used in industrial settings, where a reliable seal is essential for safety and performance reasons.

If you’re looking for a high-quality API flange chart, then be sure to visit our website at Oflange.com. We are the leading supplier of API flange specs online and offer a variety of different types of API flange slide rule online.

Our API flange table is made from high-quality materials that can withstand a wide range of temperatures, pressures, and corrosive environments.

Whether you’re looking for an API flange slide rule in carbon steel or stainless steel, we have what you need.

4. How Do You Install API Flange?

Installing an API flange requires a few simple steps. Here are those:

Gather the Correct Tools

First, make sure that you have the correct tools for the job. You’ll need a pipe wrench, a screwdriver, and a socket wrench.

Read the Manufacturer’s Manual

Before working with API welding neck flanges, it is important to use the same pressure rating system for all the specialized or custom parts respective of their pressure classes.

The best way to do this is by referring to the API flange dimensions pdf, API flange chart download, and API flange calculator included in the instruction manual provided by the manufacturer.

Clean the Pipe Thoroughly

Once you have the proper tools, you can begin the installation process for custom products with the same dimensions. Remove the old flange and clean the pipe thoroughly.

Pipe Wrench Installation

You can install the API flange bolt chart using one of two methods. The first method is to use a pipe wrench and socket wrench to remove the old flange and install the new flange.

This method works well for small pipes with simple designs. However, if you have a larger pipe or complex design, it may be difficult to get the flange sealed up.

Socket Wrench Installation

The second method is to use a screwdriver and socket wrench. This method works well for large pipes or complex designs but can be difficult on smaller pipes. You will need both tools, as well as some patience and time!

Install the Flange and Seal It

Apply a layer of sealant to the API 6A pipe and install the new flange. Tighten the screws and bolts until they are snug. Finally, test the flange for leaks.

You may need help with installing an API flange slide rule for sale depending on the type of pipe you have.

5. Benefits of API Flange

| 1 | Easy assembly |

| 2 | You can eliminate the need for adapters in the hose line, pipe, or tube |

| 3 | Pipe connections |

| 4 | Easy maintenance |

| 5 | Reduce the chance of components becoming loose |

6. 3 Tips on Maintaining an API Flange

Maintaining an API flange can be tricky, but if you follow these tips you should be able to keep it in good condition for a long time.

#1 Clean the Flange

Make sure to keep the flange clean. This means regularly wiping it down with a damp cloth to remove any dirt or debris.

#2 Inspect the Flange Regularly

Inspect the flange for damage or wear and tear regularly. If you notice any issues, address them as soon as possible.

#3 Lubricate the Flange

Lubricate the flange every few months using light oil or grease. This will help keep it in good condition and prevent wear and tear.

By following these tips, you can keep your API flange in good condition and avoid any costly repairs.

7. How Much Does an API Flange Cost?

API flanges are used in a variety of industries, such as the petrochemical and construction industries.

They are used to join two pipes together and can be made from a variety of materials, including steel, aluminum, and brass.

The cost of an API flange will vary depending on the size and material of the flange.

Steel API flanges are the most common type and typically cost between US$50 and US$100. Aluminum API flanges are less common but can be a more economical option, with prices ranging from US$30 to US$60.

Brass API flanges are the most expensive, costing between US$75 and US$125.

8. Where To Buy API Flange?

There are a few places you can buy API flange. One option is to purchase them from Oflange. Another option is to order them online.

Online Merchants

If you’re looking for a more affordable option, ordering online is probably your best bet.

Oflange

But if you want to get the highest quality API flange possible then it would be wise of you to purchase them from an actual flange manufacturer like Oflange.

9. API Flange Chart

The API flange chart contains information about flanges that are available in a variety of sizes, ranging from 1/2 inch to 72 inches. It can be made from a variety of materials, including carbon steel, stainless steel, and alloy steel.

10. API Flange Dimensions

API flange dimensions are standardized and specified in ANSI/ASME B16.5. The dimensions of an API flange are determined by the size of the pipe it is mating with, and the number of bolts required to securely fasten the flange to the pipe.

Bolt Pattern

The bolt pattern on an API flange, or the number and spacing of bolts around the circumference of the flange, is also standardized.

This bolt pattern is what determines the size of the flange. For example, a 2-bolt flange will have a smaller diameter than a 6-bolt flange.

Flange Size

The most common API Flange Sizes are

- 2 inches

- 3 inches

- 4 inches

- 6 inches

- 8 inches

- 10 inches

- 12 inches

The bolt hole sizes for these flanges also follow a standardized size, which is determined by the diameter of the flange.

For example, the bolt hole size for a 12-inch API flange will be approximately 11/16 inches.

Flange Thickness

The thickness of an API flange is also standardized by the API Flange Standard. The most common thicknesses are 0.25 inches, 0.375 inches, and 0.50 inches. However, thicker and thinner flanges are available upon request.

If you’re looking for an API Flange Specification that isn’t listed here, or if you have any other questions about API Flange Ratings, please don’t hesitate to contact us. We would be happy to help!

To know the difference between an API flange from another flange, check out this video.

11. Conclusion

If you’re in the market for an API flange, it’s important to understand the different dimensions and specs that are available.

At Oflange, we have a wide selection of flanges to choose from, and our experts can help you select the right one for your needs.

Contact us today to learn more about our products and services!