PRODUCT FEATURES

ANSI 150 Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

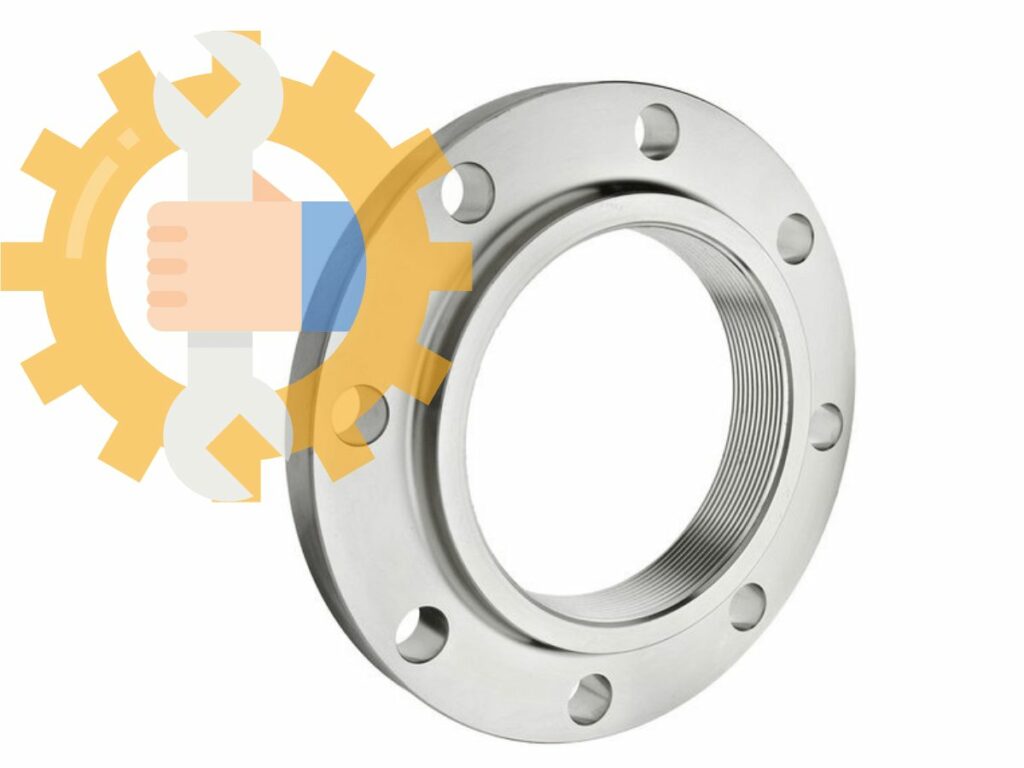

ANSI 150 Flange

If you’re in the market for an industry-standard flange, then you’ve come to the right place.

The ANSI 150 flange is perfect for any industrial or commercial application. The ANSI 150 flange also has a strong design that can withstand the pressure of high water flow rates.

It’s leak-resistant and built to last, making it a great choice for any installation. Plus, it’s easy to install, making it a hassle-free option for any project.

So, if you’re looking for more information on this type of flange, keep reading!

Table of contents

1. ANSI 150 Flange Brief Explanation

ANSI 150 flanges are a type of flange that is commonly used in plumbing and piping systems. They are made to ANSI standards and are typically rated for 150 pounds of pressure.

They are available in a catalog of sizes and materials and can be used in a variety of applications. Class 150 flanges are available in different types and dimensions such as lap joint flanges, blind flanges, and slip-on flanges.

The ANSI 150 stainless steel flanges were created in response to ANSI standards that were not specific enough and caused confusion upon the understanding and use of industry standards for flanges.

For example, length flange dimensions are in inches, usually. ANSI standards then advocated for providing dimensions in mm (millimeters) and lbs (pounds) as well to increase accuracy.

2. The Benefits of Using ANSI 150 Flange

There are many advantages of using ANSI 150 flange. Some of the most important benefits include:

Increased Strength and Durability

The ANSI 150 flange is made using a very strong, heat-treated alloy steel. This results in a flange that is resistant to wear and corrosion which can prolong the life of the other parts.

Increased Resistance to Corrosion and Wear

The ANSI 150 flange is made of alloy steel which offers increased resistance to wear, abrasion, corrosion, and stress.

Because ANSI 150 flanges can handle higher pressure than standard flanges, the ANSI 150 flange provides greater protection against leaks and can be used in more diverse environments.

Quick and Easy Installation

ANSI 150 flange is easily attached to piping with bolts or welding. ANSI 150 flanges installation requires less power because it uses bolts to fasten pipes together instead of welds.

This means the flange can be installed without requiring a large installation crew.

Reduced Likelihood of Product Failure

ANSI Flanges are tested for soundness and have high-pressure capabilities. ANSI 150 flange is made of alloy steel and provides greater protection against leaks.

3. The Difference Between ANSI 150 Flange and Other Flange Types

An ANSI 150 flange is a specialized type of flange that is designed to meet certain standards set by the ANSI (American National Standards Institute). There are a few key differences between ANSI 150 flanges and other types of flanges.

Higher-quality Raw Materials

First, ANSI 150 PN16 flanges are typically made from a higher quality material than other flanges. This means that they are more durable and less likely to fail. This means that ANSI 150 flanges can handle 150 pounds of pressure.

In comparison here are some of the other ANSI type flanges and their pressure capacity:

| Type | Capacity |

|---|---|

| ANSI B.16.5 Class 125 | 125 pounds |

| ANSI B.16.5 Class 250 | 250 pounds |

| ANSI B.16.5 Class 300 | 300 pounds |

| ANSI B.16.5 Class 900 | 900 pounds |

| ANSI B.16.5 Class 1500 | 1500 pounds |

| ANSI B.16.5 Class 2500 | 2500 pounds |

Precision Machining

Additionally, ANSI 150 PN100 flanges are precision-machined to ensure a tight fit and accurate alignment. This helps to prevent leakage and ensure a smooth flow of fluid through the pipeline.

Certified through Rigorous Standards

Finally, ANSI 150 flanges with face finish must be certified by ANSI to be used legally in the United States.

Because ANSI 150 flanges are designed to meet such precise standards, it is very difficult for a company or individual to produce ANSI 150 or ASME b16.5 flanges on their own.

To get the certification that ANSI requires, companies must have extensive knowledge of metallurgy and welding techniques. This ensures that ANSI-approved flanges meet higher quality standards than other flanges.

Suitable for Many Applications

While all flanges have some general functions in common, ANSI 150 flanges are specifically designed for high-pressure applications.

This means that they can be used in a variety of settings where other flanges would not be suitable.

4. ANSI 150 Flange Materials

The ANSI 150 Flange Materials are typically made of carbon steel, stainless steel, or alloy steel.

Carbon Steel

Carbon steel is a type of steel that has a small amount of carbon in it. This makes the steel harder and stronger than other types of steel.

Carbon steel is used in many different applications, including construction, automotive manufacturing, and oil and gas production.

One of the main benefits of carbon steel is that it can be easily machined and formed. It also has a high resistance to wear and tear, making it a popular choice for industrial applications.

Carbon steel is typically used for low-pressure applications that require a wider variety of ratings, categories, and classes compared to other specialized fittings.

Stainless Steel

Stainless steel is a steel alloy with a minimum of 10.5% chromium content by mass. Stainless steel does not corrode, rust or stain with water as ordinary steel does.

However, it is not impervious to all corrosion and can be scratched and damaged. The chromium in the alloy reacts with oxygen in the air to form a thin, invisible, inert chromium oxide film that covers the metal and prevents further oxidation.

Stainless steel flanges are typically used for applications that require corrosion resistance.

If the ANSI 150 flanges will be exposed to water, steam, or other liquids that can cause corrosion, stainless steel ANSI 150 flanges would be best.

Alloy Steel

Alloy 6 inch ANSI 150 flanges are typically used in high-pressure resistance applications. These flanges provide the ability to handle high pressure without forming cracks or any type of leaks.

5. ANSI 150 Flange Dimension

The ANSI standard gives the dimensions of a variety of pipe components, including this flange, which is designed for use in high-pressure fluid delivery systems that carry chemicals or natural gas.

The ANSI 150 flange dimensions are as follows: outside diameter (OD) for this flange is 9.5 inches, and the inside diameter (ID) is 6.625 inches with a thickness (T) of 0.312 inches.

6. ANSI 150 Flange Manufacturing Process

The ANSI 150 flange manufacturing process is a precise and intricate process that is used to create flanges that meet the requirements of the American National Standards Institute (ANSI).

Step#1 Selection of Materials

The ANSI 150 Flange Manufacturing Process begins with the selection of materials. The materials must be able to withstand the pressure and wear and tear of the flanges.

The most common material used for manufacturing flanges is stainless steel.

Step#2 Cut and Create a Hole

After the material is selected, it is cut to size and then shaped into a disc. The next step is to create the hole in the center of the disc. This is done by using a punch tool.

Step#3 Adding the Gasket Groove

The next step is to add the gasket groove. This is done by using a milling machine. ANSI b16.5, FN, RF, and FF flanges are a typical result of using the milling machine.

Step#4 Adding the Bolt Holes

The last step is to add the bolt holes. This is done by using a drill press. The drill bar operates at a wide variety of pressure (psi) based on a table number of bolt hole diameter settings.

A drill press is faster than a punch tool because it can be set up with multiple holes at once. However, the quality of each hole will not be as good as if each was drilled by hand.

7. ANSI 150 Flange Average Cost

The ANSI 150 flange average cost can range from US$50 to US$200 depending on the size and material of the flange.

Additional features such as a raised face, nominal pipe size bolt circle, modular threads, sidebar, and a larger hub for the bolt hole diameter can add to the cost substantially.

8. 8 Maintenance Tips for ANSI 150 Flange

Flanges are an important part of many piping systems, and proper maintenance is essential to keeping them in good working order.

Here are a few tips for keeping your ANSI 150 flange in top condition:

#1 Always Use a Torque Wrench

Always use a torque wrench to ensure that the flange bolts are properly tightened. This will help minimize the chance of leaks or other issues.

#2 Inspect the Flange for Wear and Tear

Inspect the flange itself for any signs of damage or wear. If any damage is found, repair or replace the flange as needed.

#3 Ensure the Good Condition and Position of the Gasket

Make sure that the gasket is in good condition and properly positioned before tightening the bolts. A damaged or misaligned gasket can cause leaks.

#4 Tighten the Bolts in a Crisscross Pattern

Tighten the bolts in a crisscross pattern, making sure to evenly distribute the torque across all of them. Do not apply too much pressure, or you could damage the flange.

#5 Clean the Surface with Soap and Water

Clean the bolts and flange surface with soap and water after installing the flange to remove any debris. This is especially important if you are using a metal gasket, as it could corrode or rust.

#6 Inspect the Gasket Before Replacing

If you need to replace the gasket, inspect the shape of it before purchasing a new one to ensure that it matches what came with your particular flange before buying anything.

#7 Watch out for Leaks

Ensure that all nuts and bolts are properly tightened into place when attaching or removing an ANSI 150 Flange. If they are not, then there is a risk of leaking at this seam.

#8 Keep in Mind the Recommended Use for the Flanges

Keep in mind that even though most flanges are manufactured to high standards such as ANSI, ASME, standards among others, you may not be able to use them in every pipe size and application.

If you have any questions about your flange or how it can best be used, please feel free to contact us at Oflange for more information.

9. Conclusion

The ANSI 150 flange is perfect for any industrial or commercial application. Plus, it’s easy to install, making it a hassle-free option for any project.

You can trust that this flange will withstand the pressure of high water flow rates. It’s also leak-resistant and built to last, making it a great choice for any installation.

Purchase your very own ANSI 150 flange today on our website at Oflange.