PRODUCT FEATURES

Aluminum Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

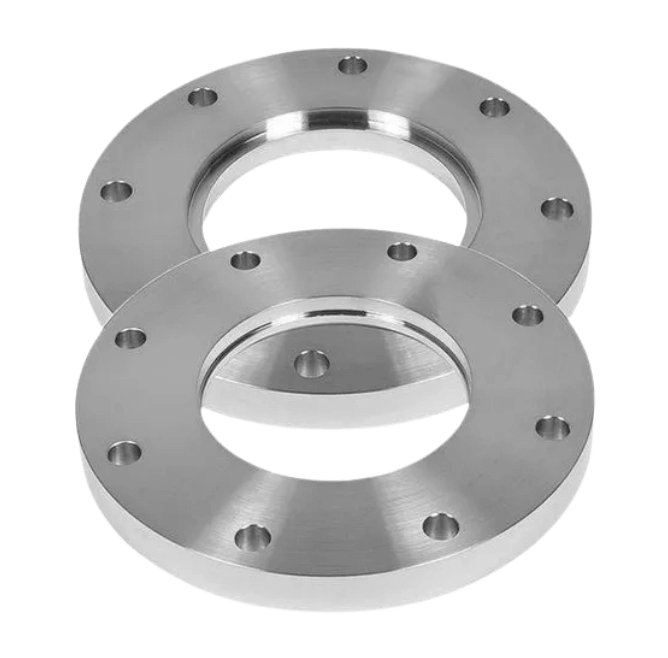

Aluminum Flange

Connecting your aluminum tubes with an aluminum flange is a fantastic alternative. It’s lightweight and resistant to corrosion, making it ideal for your project. It has a smooth finish that makes installation simple.

It is often used in aluminum railing, aluminum fencing, aluminum handrails, and aluminum stair applications. If you are building with aluminum tubing and aluminum flange will make the construction process easier.

Table of contents

1. Aluminum Flange Definition

An aluminum flange is a type of flange that is made out of aluminum. It is used to join two pieces of aluminum together. It is a very strong and durable type of flange. Aluminum flanges are easy to weld and aluminum is a very lightweight metal, making aluminum flanges ideal for aluminum welding.

Aluminum is a good conductor of heat and electricity, so aluminum flange should be used in situations where this property is desired.

2. Most Common Uses for Aluminum Pipe Flange

Aluminum pipe flanges are a type of flange that is made from aluminum. It is a lightweight metal that is corrosion-resistant. This type of flange is used in a variety of applications, including:

Home Application

An aluminum pipe flange is the most common type of aluminum flange used in home applications. Aluminum pipe flanges are lightweight and corrosion-resistant so they can be used to connect aluminum pipes indoors.

They are also easy to install because aluminum pipe flanges fit aluminum pipes perfectly, so there is no need for gaskets.

Industrial Application

Aluminum tube flange is also used in industrial applications because aluminum can be manufactured to resist corrosion or extreme temperatures. Aluminum pipe flanges have a variety of uses, including power plants, pressure vessels, gas and oil production facilities, and chemical processing plants.

Marine Application

Aluminum pipe flange is used in marine applications because aluminum is both lightweight and corrosion-resistant. Aluminum pipe flanges are often used on aluminum boats to connect aluminum pipes that transport water, gas, or oil.

Fire Protection Systems

Aluminum pipe flange is used in fire protection systems because aluminum is corrosion-resistant. Aluminum pipe flanges are commonly used on aluminum standpipes that carry water to extinguish fires.

Chemical Processing Equipment

Aluminum pipe flange is used in chemical processing equipment because aluminum is lightweight and corrosion-resistant. Aluminum pipe flanges are commonly used on aluminum tanks to connect aluminum pipes that carry chemicals. They can also be used on aluminum valves to connect aluminum hoses or aluminum piping.

HVAC Systems

Aluminum pipe flange is used in HVAC systems because aluminum is corrosion-resistant. Aluminum pipe flanges are commonly used on aluminum coils to connect aluminum valves and aluminum piping for natural gas, propane gas, steam, or water supply.

Pumps and Fans

Aluminum pipe flange is used in pumps and fans because aluminum is lightweight. They are commonly used on aluminum impellers to connect aluminum piping that carries gas or liquid for the pump. They can also be used on aluminum motor casings to connect aluminum tubing that supplies air or water for cooling purposes.

Residential Applications

Aluminum pipe flange is used in residential applications because aluminum is corrosion-resistant. Aluminum pipe flanges are commonly used to connect aluminum pipe that carries gas or water to aluminum tanks for heating appliances.

Other Applications

Aluminum pipe flange is used in other aluminum flange applications because aluminum is lightweight. Aluminum pipe flanges are commonly used on aluminum wheels to connect aluminum shafts that pass through aluminum housings or aluminum casings.

3. Identifying an Aluminum Flange

When identifying an aluminum flange, first make sure that you are looking at the correct part.

Identify the Shape

Aluminum flanges have a unique shape that distinguishes them from other types of flanges. They are typically round or oval and have a small hole in the center.

Check the Size

Check the size of the aluminum flange. Aluminum wide flange beam sizes come in different varieties, so make sure that you select the right size for your application.

Check the Thickness

Finally, check the thickness of the aluminum flange. aluminum flanges are available in a variety of thicknesses to suit your needs.

4. Other Types of Flanges and Their Features

There are many different types of flanges, each with its unique features. Some of the most common types include:

Slip-on Flanges

These flanges have a circular shape with a hole in the middle that allows them to be slipped over the end of a pipe. They are typically held in place with bolts or screws. Its feature is that it is economical and easy to use.

Socket Weld Flanges

These flanges have a square or rectangular shape and are welded to the pipe rather than slipped over it. Its feature is that it is easy to control the tightness of the seal between flange and pipe.

Threaded Flanges

These flanges have screw threads on the outside that allow them to be attached to pipes with corresponding threads. Its feature is that it offers a long-lasting tight seal when properly installed.

Lap Joint Flanges

These flanges are similar to slip-on flanges but are held in place with bolts rather than screws. They may be turned to adjust for any gaps between the pipe and flange. Its feature is that it is economical and easy to use.

Blind Flanges

These flanges allow access to the interior of a pipe or otherwise provide a cover at the end of one. Its feature is that it is economical.

Weld Neck Flanges

These are similar to slip-on flanges but are made taller to allow greater welding surface area. Its feature is that it is suitable for high-pressure and high-temperature applications.

Socket Weld Flanges

These flanges have a square or rectangular shape and are welded to the pipe rather than slipped over it. Its feature is that it is easy to control the tightness of the seal between flange and pipe.

Slipped Joint Flanges

This is an aluminum alloy, which can be used in pipe systems, the oil and gas industry. Its feature is that it is an economical, corrosion resistance aluminum alloy.

Lap Joint Flanges

This aluminum alloy flange is a smaller version of a slip-on flange with the same function but has a different design. Its feature is that the aluminum flange is lighter, a good wear resistance aluminum alloy.

Plate Flanges

These aluminum alloys have three pieces that can be bolted together to provide a seal between two pipes or objects. This aluminum alloy flange is mainly made as a standard part of the aluminum industry. Its feature is aluminum alloy aluminized flanges have a good corrosion resistance aluminum alloy.

Blind Flanges

These aluminum alloys have two pieces that can be bolted together to provide a seal between two pipes or objects, but one piece has a hole for access to the inside of the pipe. Its feature aluminum alloy aluminum flanges are mainly made as a standard part of the aluminum industry aluminum alloy aluminum flange.

Threaded Flanges

These aluminum alloys have screw threads on the outside that allow them to be attached to pipes with corresponding threads. Its feature is its aluminum flange which means the aluminum alloy is made thicker at certain places to make it stronger.

If you want to know more about aluminum flange, contact us at Oflange. We are an aluminum flange manufacturer. We can help you find an aluminum flange for your needs.

5. Process of Installing an Aluminum Flange on a Pipe or Tube

The process of installing an aluminum flange on a pipe or tube is as follows:

Step #1 Measure the Length of the Pipe or Tube

Measure the length of the aluminum pipe or aluminum tube that you are working with.

Step #2 Cut the Tube to Length

Using a saw, cut the aluminum tube to a length equal to your measurement in step 1. For optimal results, use a hacksaw. If not using a hacksaw, use another saw designed for aluminum cutting.

Step #3 Deburr the Pipe or Tube

Using aluminum deburring tools, de-burr both ends of the aluminum tube. This will provide a smooth finish and ensure that there are no sharp edges or burrs on either end of the tube.

Step #4 Drill Two Holes at Each End of the Pipe

Using aluminum drill bits, drill two holes in the aluminum flange on each end of the aluminum tube. The holes should be about an inch apart from one another.

Step #5 Insert Aluminum Flanges into Each End of the Pipe

Insert aluminum flanges into each hole. Ensure that both aluminum flanges face forward so that you can tighten them later.

Step #6 Apply Thread-Locking Agent to the Flange Bolts

Apply thread-locking agent or aluminum paste to aluminum flanges bolts. Ensure that this is done sparingly and only on the threads. This will ensure aluminum flange bolts won’t loosen later.

Step #7 Check for Looseness

Check aluminum flange and aluminum tube for looseness and movement. If you find either to be loose or moving, tighten aluminum flanges until they no longer move or lose friction with the aluminum tube.

For more information about installing the flange, watch this video.

6. The Advantages and Disadvantages of Using an Aluminum Flange

When it comes to choosing the right type of flange for your piping system, aluminum flanges have several advantages and disadvantages over other materials:

| Advantages | Disadvantages |

|---|---|

| Aluminum is a lightweight material, which makes it easier to transport and install. | Aluminum is not as strong as other materials, so it can be more susceptible to damage during installation or use. |

| Aluminum is a corrosion-resistant material, so it can be used in both indoor and outdoor applications. | Aluminum is a less expensive material than other metals, so it may not be the best option if durability is a top priority. |

| Aluminum is a thermal conductor, which means that it can dissipate heat quickly and effectively. |

In the end, aluminum flanges can be a great option for certain piping systems – especially if you need aluminum flanges in an outdoor environment.

If durability is key and aluminum flanges don’t offer enough strength to meet your needs, check out our website at Oflange for other options.

7. Common Aluminum Flange Problems and the Best Way to Avoid Them

Aluminum flanges are prone to several problems that can cause issues during use. To avoid these problems, it is important to be aware of them and take the necessary precautions.

Leakage

The most common aluminum flange problem is leakage. This can be caused by several factors, such as a poor seal or improper alignment. To reduce the chances of leakage, it is important to ensure that the flange is properly aligned and that the seal is in good condition.

Corrosion

Another common problem is corrosion. Aluminum is a soft metal and can easily corrode when exposed to moisture or other elements. To prevent corrosion, it is important to properly coat the aluminum flange with a corrosion-resistant material.

Sand Infiltration

Another aluminum flange problem is sand infiltration. Although aluminum sand castings are highly resistant to corrosion, sand particles can become trapped in the aluminum and create weak spots. To avoid sand infiltration, it is important to carefully sift sand before casting aluminum parts.

To reduce aluminum flange problems and ensure a smooth and safe casting, it is important to be aware of the aluminum flange problems and take the necessary precautions.

8. Average Cost of Aluminum Flange

The average cost of an aluminum flange is $2. The aluminum flange is a device that helps seal the connection between two pipes. It is usually made from aluminum, but brass and steel are also common materials. The price of an aluminum flange can vary depending on the size and thickness of the flange.

Below are other average aluminum flange prices per inch:

- 2 inch aluminum pipe flange: $1.75

- 3 inch aluminum pipe flange: $2.52

- 4 inch aluminum pipe flange: $3.50

If you want an exact aluminum flange quote, we recommend that you contact us at Oflange. We will provide aluminum flanges for any size, thickness, and aluminum alloy specifications and prices.

9. 3 Tips to Select the Right Aluminum Flange Dimensions for Your Needs

When selecting the right aluminum flange dimensions, there are a few things to keep in mind. Here are 3 tips to help make the process easier:

#1 Choose the Right Size for Your Project

It’s important to select a flange that is the appropriate size for the job. Too small, and it may not be effective; too large, and it may be overkill and more expensive than necessary.

#2 Consider the Type of Material You Will Be Connecting to the Flange

Some materials are more conducive to certain types of flanges than others. Make sure the flange you choose will work with the material you’re using.

#3 Think About How You Will Be Using the Flange

If it’s going to be functioning as a support for something, you will need to look at aluminum flange dimensions that are sturdier. If it is just being used as a connector between two materials, aluminum flanges with fewer supporting structures may be best suited for your project.

Flanges come in many different shapes and sizes with varying levels of aluminum flange dimensions. When shopping, keep the above tips in mind to ensure you are making the right aluminum flange purchase.

10. 3 Tips for Maintaining Aluminum Flange

Maintaining an aluminum flange can be difficult, but with a few tips, it can be a lot easier. Here are 3 tips for maintaining an aluminum flange:

#1 Clean the Aluminum Flange Regularly

Cleaning an aluminum flange regularly is very important. Most aluminum flanges are used in households, and there can be various stains on them that need to be cleaned. Stains like faded water spots or rust may make aluminum flanges look worse than they are.

#2 Lubricate the Aluminum Flange Often

Lubricating aluminum flanges often is important as well. Most aluminum flanges are used with bolts and screws, which will need to be unscrewed and screwed back in regularly. Having aluminum flange pieces that stick together can hinder the process of removing and replacing them.

#3 Keep the Aluminum Flange Away From Heat

Keeping aluminum flanges away from high heat is a good idea. Aluminum flanges can be made of aluminum, which can melt when exposed to too much heat. This is especially important if aluminum flanges are close to the oven.

In conclusion, aluminum flange maintenance isn’t that complicated with these 3 tips in mind. Follow them regularly for an aluminum flange that will last a long time.

11. Final Words

Aluminum is a lightweight and corrosion-resistant material, making it the perfect choice for your project. It has a smooth finish, which makes it easy to install.

The flange is great for connecting your tubing to create one continuous piece of piping. This product will be able to handle high-pressure applications without any problems at all!

If you want something that’s going to work well with other types of materials then this might be just what you need! We have plenty of different sizes available. Click here now and browse through our Oflange selection today!