PRODUCT FEATURES

A105 Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

A105 Flange: Specifications, Advantages, and Applications

If you’re in the business world, then you know that there are a seemingly endless number of terms and lingo that can be confusing. One such term is “A105 flange.” What is an A105 flange? And what are its specifications? How is it different from other types of flanges? And where might it be used?

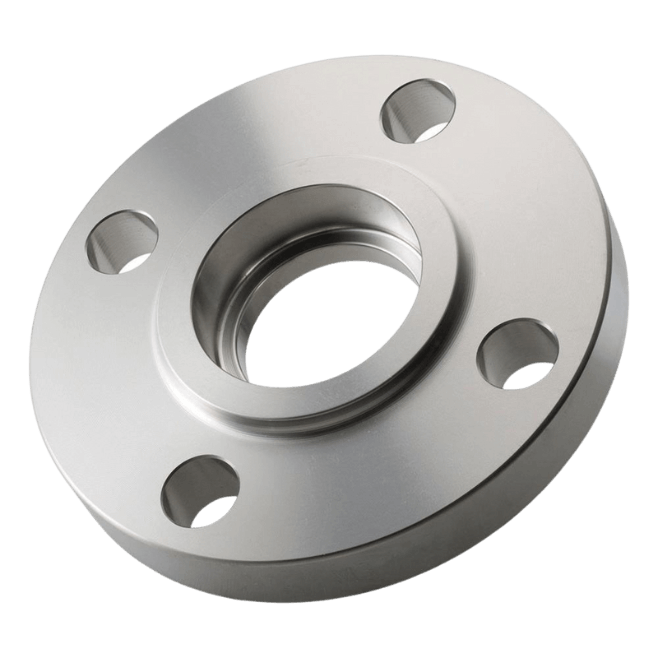

A105 flange is a type of pipe flange that’s made from forged carbon steel. It’s commonly used in high-pressure applications, and it has several advantages and applications.

In this blog post, we will discuss the specifications, advantages, and applications of A105 flanges. We’ll also provide some tips on how to select the right flange for your needs. Let’s get started!

Table of contents

1. What Is an A105 Flange

An A105 flange is a type of steel flange that is made out of carbon steel. It is a 150 rated flange, which means that it can withstand a maximum pressure of 150 psi. The flange has a hub size of 3-1/2 inches and a diameter of 6 inches. It is commonly used in piping systems to connect two pipes.

An A105 flange is a type of steel flange that is commonly used in pipelines and other industrial applications. It is made from carbon steel and has a 150 psi rating. The flange has a variety of different dimensions, depending on the size and type of pipe that it is used with.

The A350 LF2 flange is a type of steel flange that is made from low-alloy steel. It has a 350 psi rating and is commonly used in high-pressure applications. The dimensions of the flange vary depending on the size and type of pipe that it is used with.

Both the A105 flange and the A350 LF2 flange are widely used in the industrial sector. They are both made from 150 carbon steel flange dimensions, which makes them strong and durable. The 150 psi rating on both of these flanges also makes them ideal for use in high-pressure applications.

When choosing a steel flange, it is important to consider the type of pipe that it will be used with, as well as the rating of the flange. This will ensure that you select a flange that is best suited for your needs.

2. Applications of A105 Flange

The A105 flange is an a105 carbon steel flange that is used in a variety of applications. Some of the most common applications include:

Pipe Fittings

A105 flange Pipe Fittings are the most commonly used type of flange. They are made from ASTM a105 carbon steel and have a 150 rating. The dimensions of a carbon steel flange are important to consider when ordering or manufacturing these fittings.

Flanged Joints

Flanged joints are a type of bolted joint that uses a flange on one or both of the connected members to distribute the load. This type of a105 carbon steel flanges joint is commonly used in piping and tubing systems. The flanges are usually made from steel, aluminum, or brass, and the bolts are made from steel.

Valve Coverings

A105 flange is a common choice for valve coverings. It is made from a105 steel flange and has dimensions of 3-1/2 inches by 3-1/2 inches. A350 LF2 flanges are also a common choice for valve coverings. They are made from high-quality stainless steel and have dimensions of 4 inches by 4 inches.

Manhole Covers

A105 flanges are often used in manhole covers. A350 LF2 flanges are a higher-strength option, but a105 steel flanges dimensions are also common. It’s important to select the right flange for the job, as improper selection can lead to leaks or other problems.

The A105 flange is a reliable and versatile option for many applications. It is made from carbon steel a105, which makes it durable and strong. It also has a 150 rating, which means that it can handle high pressure and temperatures.

3. How Do I Know if My Pipe Has an A105 Flange Connection?

If you’re not sure if your pipe has an A105 flange connection, there are a few ways to find out.

Check the Pipe Dimensions

One way is to check the pipe’s dimensions. If the pipe’s dimensions match those of an A105 flange, then the pipe likely has an A105 flange connection.

Check the Material Type

Another way to determine whether a pipe has an A105 flange connection is to check the material type. If the pipe is made of carbon steel, then it likely has an A105 flange connection.

Check the Flange Type

Finally, you can also check the flange type. If the flange is a 150 carbon steel flange, then it likely has an A105 flange connection.

4. Type of Bolts Should Be Used With an A105 Flange Connection?

When choosing the type of bolts to use with an ASTM a105 flanges connection, it is important to consider the chemical and mechanical properties of the flange material a105 involved. In most cases, a grade 150 carbon steel bolt should be used.

However, if the flange is made from low-alloy steel such as A350 LF2, then a bolt circle made from a similar alloy should be used.

Grade 150 carbon steel bolts are typically used in conjunction with a350 lf2 flanges. The bolts have a higher tensile strength than grade A307 bolts and can withstand higher pressure. Grade 150 carbon steel bolts are also available in a variety of finishes, including black oxide, zinc plated, and hot-dipped galvanized.

5. Installing an A105 Flange Connection on a Pipe Fitting System

Installing an A105 Flange Connection on a Pipe Fitting System is a relatively simple process that can be completed with a few basic tools.

Step #1 Clean and inspect the Flange Bolts

First, the flange must be cleaned and inspected for any damage or defects. The flange bolts must also be inspected and cleaned, if necessary.

Step #2 Cut the Pipe

Once the flange is ready to be installed, the pipe must be cut to the desired length and deburred.

Step #3 Insert the Pipe On the Top

The pipe must then be inserted into the fitting and the flange bolted on top. If needed, the gasket can be lubricated with petroleum jelly to help it slip into place more easily.

Step #4 Tighten the Bolts

Finally, the bolts should be tightened evenly until the flange is secure.

If you have any questions about A105 Flange Don’t hesitate to contact Oflange.com today!

To know more about how to install flanges, check out this video.

6. A105 Flange Dimensions

The dimensions of an A105 flange can vary depending on the type and size of the flange. However, in most cases, the dimensions will be as follows:

| Flange Width | ¾ inches and 11/16 inches |

| Flange Thickness | ½ inches and ¼ inches |

| Bolt Circle Diameter | 0.625 inches and 0.75 inches |

| Number of Holes | 4 holes |

| Pipe Size | ½ inches and 24 inches |

Flange Width: The width of the flange is typically between ¾ inches and 11/16 inches.

Flange Thickness: The thickness of the flange is typically between ½ inches and ¼ inches.

Bolt Circle Diameter: The bolt circle diameter is typically between 0.625 inches and 0.75 inches.

Number of Holes: The number of holes can vary depending on the type of flange, but in most cases, there will be 4 holes such as those in welding neck flange coupled with carbon steel blind flanges.

Pipe Size: The pipe size will typically be between ½ inches and 24 inches.

If you need a custom A105 flange, Oflange can help! We offer a variety of sizes and types to choose from.

7. A105 Flange Manufacturers

A105 flanges are made from carbon steel and designed for high-pressure and high-temperature applications. Several A105 flange manufacturers produce these types of flanges, including:

Oflange

Oflange is a leading supplier of high-quality A105 flanges. Our products are designed for maximum strength and durability, and we offer a variety of sizes and types to choose from. If you’re looking for a reliable A105 flange supplier, look no further than Oflange!

Alcoa

Alcoa is a leading global producer of primary and fabricated aluminum, as well as the world’s largest producer of alumina and a105n flange. The company has approximately 61,000 employees in 31 countries. Alcoa operates production facilities in 4 regions: North America, South America, Europe, and Asia.

Bekaert

As a leading manufacturer of A105 flanges, Bekaert offers a wide range of sizes and pressure ratings to meet the most demanding applications. Our products are manufactured to the highest quality standards of a105 forged steel flanges, ensuring reliable performance and long service life.

American Piping Products Company Inc

American Piping Products Company Inc (APP) is a leading manufacturer of a105 flanges. The company has a rich history dating back to the early 1900s when it began producing forged steel and alloy flanges for the oil and gas industry.

Today, APP continues to be a leading supplier of a105 flanges and other piping products, thanks to its commitment to quality and customer service.

MRK-Schneider Systems, LLC

MRK-Schneider Systems, LLC is a leading provider of a105 flanges and other piping components. We offer a wide range of products and services to meet the needs of our customers, and our team of experts is available to help you find the right solutions for your project.

8. A105 Flange Specification

Specification of A105 Flange is ASTM A105/A350 LF-0. The flange is made from carbon steel and has a minimum yield strength of 55,000 psi. ASTM a105 flange specification is designed for use in high-pressure applications up to 150 psi (gauge). The flange has a diameter of 12 inches and a thickness of 0.562 inches.

Size: 1/2 inches to 48 inches

Standards: ANSI B16.47 Series A & B, MSS SP44, AWWA, Custom Drawings, ASA, ANSI B16.5, API-605.

Pressure Ratings: Class 400, Class 150, Class 1500, Class 300, Class 900, Class 2500, Class 600

Flange Face Type: Flate Face, Raised Face, Carbon Steel Ring Type Joint

Coating/Surface Treatment: Yellow Transparent, Oil Black Paint, Anti-rust Paint, Cold and Hot Dip Galvanized, Zinc Plated.

[end of table]

9. Types of A105 Flange

A105 flange is a type of flange that is made from carbon steel. It is a standard, non-alloy flange that is used in low-pressure applications. A105 flanges are available in three types: weld neck, slip-on, and socket weld.

Weld Neck

Weld neck flanges are the most popular type of ASTM a105 flanges. They are commonly used in high-pressure applications. The weld neck flange has a long neck that connects to the pipe with a weld. This type of flange is strong and can withstand high levels of pressure.

Slip-On

Slip-on flanges are easy to install and are the most common type of flange. They are available in both carbon steel and stainless steel. Socket weld flanges are similar to slip-on flanges, but they have a socket weld that connects the pipe and the flange.

Socket Weld

Socket weld flanges are fittings that are welded onto the end of a pipe. They are used to join two pipes together. The weld is made on the inside of the fitting, so it is not visible from the outside. Socket weld flanges are made from steel and come in different sizes.

If you are looking for a high-quality A105 flange, then be sure to contact one of the many reputable A105 flange manufacturers. Contact us at Oflange today!

10. 3 Tips for Maintenance of A105 Flanges Connections

The flanges connection is a critical part of the pipeline system. It is important to maintain the flanges connection to ensure that the pipeline system continues to operate safely and efficiently.

There are a few tips that can help with the maintenance of the flanges connection:

#1 Check for Leaks or Signs of Damage Regularly

It is important to check for leaks or any signs of damage on A105 flanges connections regularly. This will help to avoid any potential problems and ensure that the connection remains safe and effective. If any leaks or damage are found, it is important to take action right away to prevent further issues.

#2 Make Sure That The Bolts Are Properly Tightened

A105 flanges connections can be maintained by ensuring that the bolts are properly tightened. This can be done by using a torque wrench to tighten the bolts to the correct specifications. Overtightening the bolts can cause damage to the flange connection, so it is important to make sure that they are tightened correctly.

#3 Lubricate the Gaskets and Seals Regularly

Lubricating the gaskets and seals on a105 flanges connections is an important part of regular maintenance. Without lubrication, the seals and gaskets can become dry and brittle, which can lead to leakage. It is best to lubricate the seals and gaskets regularly, at least every six months.

11. Conclusion

If you need an A105 flange for your business, please do not hesitate to contact us at Oflange. We would be more than happy to provide you with the best product possible.

Our team has years of experience and is more than capable of meeting your needs. Additionally, we offer competitive prices and quick turnaround times. Thank you for considering our company as your go-to source for all things related to A105 flanges.