PRODUCT FEATURES

Flange 150 Lbs Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

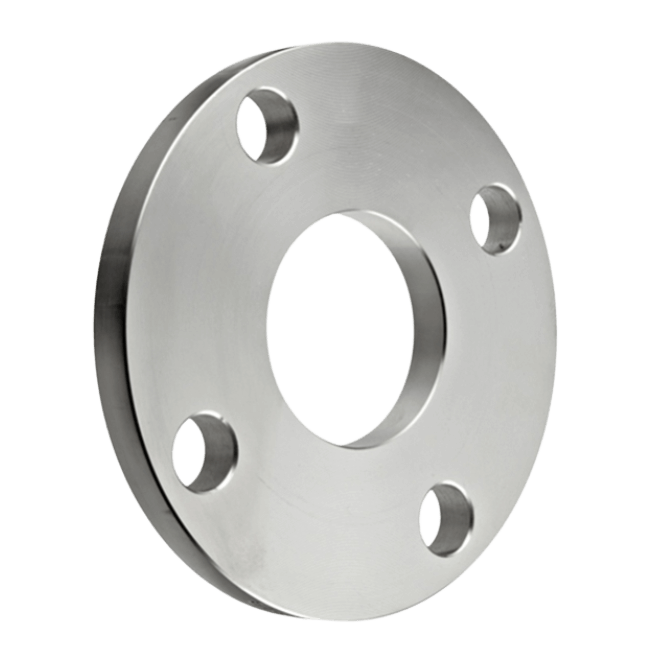

Flange 150 lbs.

If you work in the industrial or piping industry, you’ve probably come across ANSI Flange 150 lbs. But do you know what they are?

The ANSI Flange 150 lbs is a heavy-duty, versatile, and durable product. It provides superior strength with increased durability, allowing for versatility in almost any application.

In this blog post, we’ll also discuss some of the key benefits of using the flange in your projects. By the end of this post, you’ll have a better understanding of why ANSI 150 flanges are so popular among process engineers. Let’s get started!

Table of contents

1. Flange 150 lbs. Definition and Its Uses

The ANSI Flange 150 lbs is a type of flange that is commonly used in industrial settings. It is made from cast iron and has a 150-pound dimensions pressure rating.

150lb flanges can be used in a variety of applications, such as piping, valves, and pumps. It is also commonly used in the construction of buildings and other structures.

The ANSI Flange 4 150 lbs is a reliable and durable flange that can handle high pressures. It is made from cast iron, which makes it strong and sturdy.

The 150-pound pressure rating ensures that it can handle heavy loads without fail. And the wide variety of applications in which it can be used makes it a versatile flange that is ideal for many industrial settings.

2. Flange 150 lbs. Composition

The ANSI 150lb flange composition is made up of several different materials. The flange is designed to be durable and withstand a lot of pressure.

It is also made to be corrosion-resistant. The materials used in the 150 flange composition include:

- Carbon steel

- Stainless steel

- Alloy steel

These materials are all combined to create a flange that is strong and resistant to wear and tear. The ANSI 150 flange dimensions composition is also designed to be heat-resistant, so it can withstand high temperatures without corroding.

If you want to learn more about what composes a Flange 150 lbs, feel free to contact us at Oflange.

3. The Manufacturing Process of a Flange 150 lbs.

The ANSI flange 150 lbs is a type of industrial pipe flange that is commonly used in high-pressure applications. It is designed to withstand high levels of stress and pressure, making it a popular choice for many industrial and manufacturing settings.

Manufacturing a class 150 flange typically involves the following processes:

Step#1 Selecting the Right Material

The manufacturing process of an ANSI flange 150 lbs begins with the selection of the right material. Depending on the application, different materials may be used, such as carbon steel, stainless steel, or aluminum.

Step#2 Creating a Flange Blank

The next step in manufacturing a neck flange 150 lbs. is to create a flange blank. This can be done using a variety of methods, including casting, forging, or machining.

Step#3 Forming the Flange Blank into the Desired Shape

After the flange blank is created, the next step is to form it into the desired shape, bolt circle dia, and flange thickness. This can be done using a variety of methods, including stamping, spinning, or die casting.

Step#4 Welding the Flange to the Pipe

The next step is to weld the bolt hole diameter flange to the pipe flanges. This can be done using a variety of methods, including gas metal arc welding, shielded metal arc welding, or submerged arc welding.

Step#5 Testing the Quality of the Welds

After the blind flange is welded to the pipe, the next step is to test the nominal pipe size and quality of the welds. This can be done using a variety of methods, including visual inspection, radiography, or ultrasonic testing.

Step#6 Finishing the Flange

The last step in manufacturing a flange 150 lbs. is to finish it. This can be done using a variety of methods, including polishing, painting, or galvanizing.

By understanding the detailed manufacturing process of an ANSI Flange 150 lbs., you can better understand how they are made and what to look for when purchasing them.

4. The Different Class of Flange 150 lbs.

There are three different types of ANSI flange classifications: 150 lbs., 300 lbs., and 600 lbs. Each class has a unique design that affects how the flange is manufactured and how it functions.

| Type | Features |

|---|---|

| ANSI Class 150 Flanges | The 150 lbs. flange is the lightest and most commonly used type. It is made from a thin metal plate that is bent into a circular shape and has three bolt holes in the center. This flange is designed for use with light-duty pipes and fittings and can withstand up to 150 pounds of pressure. |

| ANSI Class 300 Flanges | The flange 300 lbs are thicker and stronger than the 150 lbs. flange. It is made from a thicker metal plate and has six bolt holes in the center. This flange can withstand up to 300 pounds of pressure and is typically used with heavier-duty pipes and fittings. |

| ANSI Class 600 Flanges | The 600 lbs. flange is the strongest and most durable type. It is made from a thick metal plate and has twelve bolt holes in the center. This flange can withstand up to 600 pounds of pressure and is typically used with the heaviest-duty pipes and fittings. |

If you are not sure which class of flange you need, consult with us at Oflange. We will be able to help you choose the right flange for your application.

5. Advantages and Disadvantages of Flange 150 lbs.

The ANSI Flange 150 lbs. has a variety of advantages and disadvantages that are worth taking into account.

Advantages

Some of the advantages include its high strength and low weight. This makes it perfect for use in a variety of applications. Additionally, the ANSI Flange 150 lbs. is resistant to corrosion and abrasion, which increases its durability.

Disadvantages

On the other hand, some of the disadvantages of the ANSI Flange 150 lbs. include its susceptibility to damage and its high cost. Additionally, it can be difficult to find a qualified professional to install this type of flange.

Overall, the ANSI Flange 150 lbs. is a high-quality option that has a variety of benefits. However, it is important to consider the disadvantages before making a purchase.

6. Applications of Flange 150 lbs. in Various Industries

The ANSI flange 150 lbs is a common type of flange that is found in many industries. It has several applications, including:

Construction Industry

Flanges are often used in the fabrication of metal structures such as beams, girders, and columns.

Automotive Industry

Flanges are used to join body panels and chassis components.

Piping Industry

Flanges are used to connect pipes and tubes.

Manufacturing Industry

Flanges are used to join machine parts together.

Medical Industry

Flanges are used to connect medical equipment via interlinks.

Food and Beverage Industry

Weld neck Class 150 flanges are used to connect tanks and piping.

Oil and Gas Industry

Flanges are used in pipelines and other infrastructure.

The ANSI flange 150 lbs is a versatile type of flange that is widely used in many industries. It is strong and durable and can withstand the high pressures and temperatures found in some industrial applications.

It is also easy to install and can be used with a wide range of pipe sizes and materials. For these reasons, the ANSI flange 150 lbs is a popular choice for many industrial applications.

7. Flange 150 lbs. Average Cost

The ANSI flange 150 lbs. average starting cost is US$10 to US$30 for each flange.

8. Where to Purchase Flange 150 lbs. in Bulk

When looking to purchase ANSI flange 150 lbs in bulk, there are a few different places you can go.

Oflange

If you’re looking for a place to purchase ANSI flange 150 lbs. in bulk, you can check out the website of flange manufacturer, Oflange.

They have a wide selection of ANSI flange sizes and materials, and they can deliver the flanges to you quickly and efficiently.

Online Suppliers

One option is to search online for a supplier. There are many retailers that carry this type of product, and it can often be found at a discounted price.

Local Distributors

Another option is to check with local distributors in your area. They may be able to point you in the right direction or even sell you the flanges outright.

Whichever route you decide to take, make sure to do your research and compare prices before making a purchase.

9. 7 Tips to Select the Right Flange 150 lbs. for Your Needs

When it comes to selecting the right ANSI flange 150 lbs., there are a few things you need to take into consideration. Here are some tips to help you make the best decision for your needs:

#1 Understand the Specifications

Make sure you understand the specifications of the flange, such as temperature ratings and raised face dimensions. ANSI flanges come in a variety of sizes, wall thickness, and materials, so be sure to select one that is dimension compatible with your needs.

#2 Consider the Usage Environment

Consider the environment where the flange will be used. If it will be used in a high-temperature or corrosive environment, be sure to select a material that is resistant to those conditions.

#3 Check the Compatibilities

Make sure the flange is compatible with the pipe size and type you are using. ANSI flanges come in a variety of sizes and shapes, so be sure to select the right one for your needs.

#4 Consider the Weights

Consider the weight of the flange. ANSI flanges can weigh anywhere from 2 to 200 pounds, so make sure you select one that is appropriate for your application.

#5 Choose the Correct Seals

Make sure the flange works with the type of seal you are using. ANSI flanges come with a variety of seals, so be sure to select the right one for your needs.

#6 Consider the ANSI Pressure Ratings

Make sure the flange is compatible with the type of pressure you are using. ANSI flanges come in a variety of pressure ratings, so be sure to select the right one for your needs.

When choosing a flange, it is important to consider the ANSI rating. ANSI flange ratings indicate the pressure that a flange can withstand.

In order to select the right flange for your needs, you must first determine the maximum pressure that your system will experience. Then, choose a flange with an ANSI rating that is greater than or equal to the maximum pressure.

#7 Consider the Material Types

Another factor to consider when selecting a flange is the type of material. There are three main types of materials used in flanges: alloy steel, stainless steel, and carbon steel.

Each material has different properties that can affect how the flange face drilling template performs. For example, alloy steel is more resistant to cracking than stainless steel.

By following these tips, you can select the right ANSI flange for your needs. For more information, please contact us at Oflange.

10. Conclusion

This product is perfect for any industrial or piping application. It provides superior strength and increased durability, making it the perfect choice for your needs.

With its versatile design, the ANSI Flange 150 lbs can be used in almost any application. So if you’re looking for a durable and reliable flange, this is the product for you!

Purchase an ANSI Flange 150 lbs today on our website at Oflange.com!