PRODUCT FEATURES

Blind Flange with Tap Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

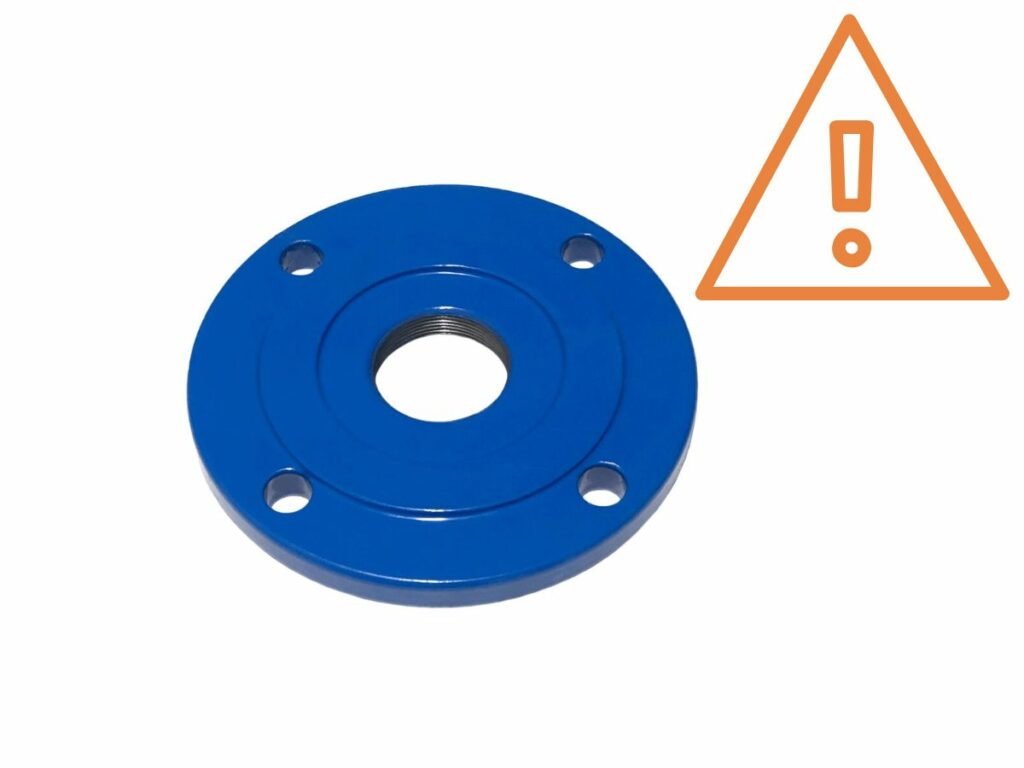

Blind Flange with Tap

A blind flange with a tap is a type of flange that has a threaded hole in the center. This type of flange is used to connect two pipes, and it can also be used to create a seal between two pieces of pipe.

The blind flange with tap is often used in applications where it is necessary to tighten or loosen the connection between two pipes. This type of flange is also commonly used in plumbing applications.

There are several situations where it might be necessary to use a blind flange with a tap. One common application is when you need to create a seal between two pieces of pipe. In this situation, the blind flange with a tap can be used to connect the two pieces of pipe.

Table of contents

1. Applications of a Blind Flange With Tap

The following are some common applications of Blind Flange with Tap:

Part of a Piping System

One common application for a blind flange with tap is as part of a piping system. The blind flange with tap can be used to create a seal between two pipes, while the tap can be used to allow fluid to flow between the pipes. This allows for easy maintenance and troubleshooting of the piping system.

Manufacturing of Plastic Bottles

Another common application for a blind flange with a tap is in the manufacturing of plastic bottles. The blind flange with tap is used to create a seal between the bottle and the cap, allowing for easy assembly and filling of the bottle.

Without the blind flange with a tap, it would be difficult to create a seal between the two pieces and the bottle would likely leak.

Can Be Used in Conjunction With a Valve

The blind flange with tap can be used in conjunction with a valve to create a closed system, and it is also used on similar valves and pressure vessel openings. This allows for precise control over the flow of fluid through the system.

By using a blind flange with a tap in this way, you can minimize the amount of fluid that escapes from the system. To know more about blind flanges and their uses, watch this video.

2. Installation of Blind Flange With Tap

Here is a step by step guide on how to install a blind flange with tap.

| 1 | Preparing the Blind Flange |

| 2 | Drilling the Hole |

| 3 | Tapping the Hole |

| 4 | Installing the Blind Flange With Tap |

| 5 | Testing the Blind Flange With Tap |

Step #1 Preparing the Blind Flange

The first thing you need to do is to prepare the tapped blind flange. To do this, you need to clean the area around the hole that will be tapped. This is important because you want to make sure that no debris or dirt could get into the threads and cause them to become clogged.

Step #2 Drilling the Hole

Once the area around the hole is clean, you can start drilling the hole. Make sure that you use a bit that is the same size as the tap that you will be using. If you are not sure what size to use, consult with the manufacturer of your blind flange.

Step #3 Tapping the Hole

Once the hole is drilled, you can start tapping it. Again, make sure that you use the correct size for your drilled and tapped flanges. If you are not sure what size to use, consult with the manufacturer of your blind flange.

Step #4 Installing the Blind Flange With Tap

After the blind flange drilled and tapped procedures are done, you can now install the blind flange. First, you need to thread the tap into the blind flange. Make sure that you are doing this correctly so that the threads do not become cross-threaded.

Once the tap is in place, you can start screwing on the blind flange. Make sure that you are doing this evenly so that the blind flange is installed correctly.

Step #5 Testing the Blind Flange With Tap

After the blind flange is installed, you need to test it to make sure that it is working correctly. A pressure test connections is the best way to do this.

To do a pressure test, you need to have a pump that can generate enough pressure to test the blind flange with tap. You also need to have a valve that will allow you to release the pressure in case of an emergency.

If everything is working correctly, the National Pipe Thread or NPT tapped holes should be able to hold the pressure without leaking. If there are any leaks, you need to find the source of the leak and repair it before using the blind flange.

3. Advantages of Using a Blind Flange With Tap

Here are the advantages of using a blind flange with tap:

Easy to Install

One of the advantages of using a blind tapped flange is that it is easy to install. You don’t need to weld or use any special tools to install it.

Reduced Pressure Loss

The blind flange with tap can help reduce pressure loss in your system. This is because it creates a more efficient flow of fluid through the pipe. As a result, you will experience less pressure loss and improved performance.

Improved Performance

By using a blind flange with tap, you can improve the performance of your system. This is because it helps reduce pressure loss and makes the flow of fluid more efficient. As a result, you will experience less drag on your system and improved performance.

4. Cost of a Blind Flange With Tap

The cost of a blind flange with tap can vary depending on the size and type of blind flange you need. The average cost of a blind flange ranges from USD 50 to USD 200. Blind flange with tap can be found at most hardware stores and online retailers such as Oflange.

However, as a general rule, the cost for a blind flange with tap will be more expensive than a standard blind flange. This is because the tap makes it easier to attach and remove the blind flange from the pipe, which can save you time and money in the long run.

When purchasing a blind flange, it is important to select the correct size and type for your needs. Blind flanges are available in a variety of sizes, from small diameter blind flanges to large diameter blind flanges.

5. When To Use a Blind Flange With Tap and When You Should Not

Here are some situations where you should use a blind flange with tap, and others where you should not:

When to use a blind flange with tap

- When you need to seal two pieces of pipe together.

- When you need to plug a hole in a pipeline.

- When you want to prevent fluid from flowing through a certain section of the pipe.

When not to use a blind flange with tap

- When you want to allow fluid to flow through the pipe.

- When you need to connect two pieces of pipe.

- When you want to open a hole in a pipeline.

6. 6 Tips How To Inspect, Test and Maintain a Blind Flange With Tap Connection

Just like any other blind flange, it is important to inspect, test and maintain a blind flange with tap connection to ensure that it is functioning properly. Since blind flanges are often located at the end, these flanges are among the highest stressed flange types.

Here are some tips on how to do so:

#1 Inspect the Blind Flange For Any Damage or Wear and Tear

It is important to inspect the blind flange for any damage or wear and tear. If you find any damage, you will need to repair it before using the blind flange.

#2 Immediately Replace a Damaged Blind Flange

If a blind flange with a tap connection is damaged, it must be replaced immediately. Depending on the severity of the damage, you may be able to repair it with a blind flange kit. If the damage is too severe, however, you will need to replace the entire blind flange.

#3 Test The Blind Flange For Leaks

Once you have inspected the blind flange for any damage or wear and tear, you should test it for leaks. To do this, you can use a pressure testing kit.

If there are no leaks, then the blind flange is functioning properly.

#4 Make Sure That the Blind Flange is Properly Aligned

It is also important to make sure that the blind flange is properly aligned. If it is not, it could cause leaks. You can use a spirit level to check the alignment of the blind flange. If it is properly aligned, then you are ready to use it. If not, you will need to adjust it before using it.

#5 Keep the Blind Flange Clean

It is also important to keep the blind flange clean. This will help to prevent any leaks from occurring. You can clean it with a rag or a brush.

#6 Inspect the Blind Flange Regularly

It is important to inspect the blind flange regularly. This will help to ensure that it is functioning properly and that there are no leaks. You can inspect it once a month or whenever you think it is necessary.

There are not so many tapped blind flange requirements to consider when compared to other types of blind flanges. The main thing is the blind flange must be able to withstand the maximum working pressure and temperature of the system it will be used in.

7. Types of Blind Flanges With Tap

Here are the different types of blind flanges with tap.

Flat Face (FF) Blind Flange With Tap

A flat face blind flange with tap is a type of blind flange that has a flat face. It is used to seal off the end of a piping system or vessel. This type of blind flange is most commonly used in high-pressure and high-temperature applications.

Raised Face (RF) Blind Flange With Tap

A raised face blind flange with tap is a type of raised face blind flange that has a threaded hole in the center. This type of blind flange can be used to connect two pieces of pipe or to attach a valve to the pipeline. The tapped blind flange allows for easy installation and removal of the valve, which makes it a popular choice for many applications.

8. Potential Problems When Using a Blind Flange With Tap and How To Prevent Them

Here are the potential problems when using a blind flange with tap and how to prevent them.

Leakage

A blind flange with tap may leak if it is not installed correctly. To prevent leakage, it is important to follow the manufacturer’s instructions carefully and to use the proper tools and techniques when installing the blind flange.

Incorrectly Sized Blind Flange With Tap

If a blind flange with tap is incorrectly sized, it may not seal properly. This can cause leakage or other problems. To ensure that the blind flange is the correct size, it is to use the proper tools when measuring the pipe.

Improperly Torqued

The blind tapped flanges must be properly torqued to prevent leaks. If the blind flange is not properly torqued, it may leak. To prevent this problem, it is important to follow the manufacturer’s instructions carefully and to use the proper tools when installing the blind flange.

Cross-Threading

Cross-threading is a common problem when using a blind flange with tap, most especially if it is a blind flange with 2 tap. This can be prevented by using a properly sized tap.

Using the Wrong Size Tap

Using the wrong size tap can cause problems when using a blind flange with tap. Make sure to follow the manufacturer’s instructions carefully to ensure the correct size tap is used.

Blind flanges with taps are a popular choice for many applications because they are easy to install and remove. However, there are potential problems that can occur if they are not installed correctly. Make sure to follow the manufacturer’s instructions carefully to avoid these problems.

9. Conclusion

Blind flanges with tap are a great way to connect two pieces of pipe. They provide a tight seal that prevents leaks, and they can be used in both water and gas systems. When choosing a blind flange with tap, make sure you select the right size and type for your application.

If you are looking for a reliable, leak-proof way to connect two pieces of pipe, a blind flange with tap is the perfect solution. We carry a wide variety of sizes and types to suit your needs.

So be sure to browse our selection and contact us at Oflange if you have any questions. Thanks for reading!