PRODUCT FEATURES

ASA 150 Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

ASA 150 Flange: What You Need to Know

When it comes to valves and piping, an ASA 150 flange is a critical component. But what is it, exactly? How do you know if your piping system needs one? And what are the benefits of using an ASA 150 flange?

In this blog post, we’ll answer all those questions and more. We’ll start by explaining exactly what an ASA 150 flange is, and then we’ll discuss the benefits of using one in your piping system. Let’s get started!

Table of contents

1. What Is an ASA 150 Flange

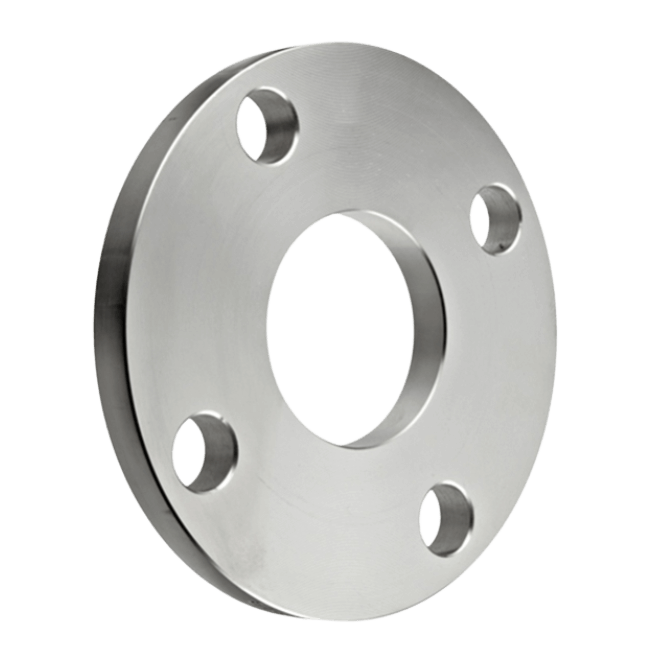

An ASA class 150 flange standard flange is a type of flange that is commonly used in the United States.

It has an American Standard Association (ASA) 150 rating, which means that it is designed to withstand a pressure of up to 150 pounds per square inch. It also comes in other names such as ASME b16 5 class 150 and ANSI b16 5 class 150.

ASME is the American Society of Mechanical Engineers while ANSI is the American National Standards Institute. Both are governing bodies that determine guidelines when it comes to the ASA flange size chart, ASA flange dimensions, and other ANSI ASME related products.

The flange is used in a variety of applications and industries. It can be found as part of a pipe, as well as other machinery parts such as material for weld neck and socket weld contact tables.

The ASA 150 flange has an ASA rating that indicates the amount of pressure it can withstand before cracking or breaking.

An ASA 150 flange is used in many industries and applications throughout the United States. These include oil refineries, chemical plants, industrial facilities, as well as other places where a high-pressure environment is present.

2. Uses of ASA 150 Flange

The ASA 150 Flange is used as a connector in pipe systems. It is commonly used in the transportation and distribution of water, oil, and gas. The flange can also be used as a connector in fire protection systems and HVAC systems.

3. Identifying an ASA 150 Flange

An ASA 150 flange is easily identifiable by its dimensions, rim, and bolt circle.

The ASA 150 Flange is made of cast iron and has a pipe size of 150 mm. It has a thickness of 14 mm and a diameter of 203.20 mm. The flange has 4 bolt holes that are 12.70 mm in diameter. It also has a pressure class of 150 lbs.

4. Dimensions of an ASA 150 Flange

The minimum dimensions range of an ASA 150 flange are as follows:

| Inner Diameter | 150mm |

| Outer Diameter | 177.8mm |

| Thickness | 10.2mm |

| Bolt Circle | 165.0mm |

| Number of Bolts | 12 |

| Hole Diameter | 11.13mm |

| Distance from Center of Hole to Edge of Flange | 19.05mm |

The dimensions may vary slightly depending on the manufacturer, so be sure to check with your supplier before ordering. Keep in mind that flange ASA 300 is also usually available, this flange has a diameter of 300mm.

If you’re not sure which flange is best for your application, feel free to contact us at Oflange.

As a leading manufacturer of ASA 150 flanges in China, we can produce high quality ASA 150 flanges as per your requirements. If you want to know more about ASA 150 flanges, Oflange is your perfect choice!

5. ASA Class 150 Flange Standard

The ASA Class 150 Flange Standard is a set of specifications that covers flanges, gaskets, bolts, and nuts used in pipe joints.

The standard was developed by the American Society of Mechanical Engineers (ASME). It specifies dimensions for flanges and gaskets, as well as bolt and nut sizes. The standard is widely used in the United States and other countries.

If you are looking for ASA 150 flanges, bolts, or gaskets that meet asa 150 specifications, visit our website at Oflange.com.

We have a wide selection of ASA 150 class flanges and related products. Our ASA standard is certified by both the American Society of Mechanical Engineers (ASME) and the American National Standards Institute (ANSI).

6. Manufacturing Process of ASA 150 Flanges

The ASA 150 flange is a type of pipe flange that is commonly used in the transportation and petrochemical industries.

The ASA 150 flange is manufactured from forged carbon steel and is designed to withstand high pressures and temperatures. The manufacturing process of an ASA 150 flange typically includes the following steps:

Preparing the Blank Flanges

The first step is to prepare the blank flanges. This involves cutting the sheets of steel to the desired size and then drilling the required holes in them.

Forming and Forging the Flanges

Once the holes are drilled, the next step is to form the flanges. This is done by bending the steel around a die.

The forging process begins by heating a piece of carbon steel to a temperature of approximately 2,200 degrees Fahrenheit, this has an error margin of 3-4 degrees.

The forged steel is then cooled in water or air to room temperature.

Welding the flanges

The next step is to weld the flanges together. This is done by welding the edges of the flanges together.

Machining the flanges

The final step is to machine the flanges. This is done by cutting the flanges to the desired size and shape. The steel is then machined as needed to create the desired specifications, as well as any holes that are required.

The manufacturing process of an ASA 150 flange typically includes several hundred steps, with each step being measured and documented by quality control personnel.

This ensures that all products conform to ASA standards as specified in ANSI B16/36-1996 standard specification for aluminum and aluminum alloy flanges.

By using high-quality materials and following a stringent manufacturing process, ASA flanges can be relied on to provide years of reliable service.

7. Tolerances of ASA 150 Flanges

The tolerances of ASA 150 flanges depend on the class of the flange. For Class 150 flanges, the tolerances are as follows:

- The thickness of the flange at the thinnest point should not be less than 3/8 inches.

- The width of the flange at the narrowest point should not be less than 1 inches.

- The thickness of the flange at the thickest point should not be more than 1-1/2 inches.

- The width of the flange at the widest point should not be more than 2 inches.

- The bolt hole diameter should not be more than 0.406 inches and less than 0.375 inches.

- ASA 150 flanges have a raised face with a height of at least ¼ inch.

8. Pressure Class and Temperature Ratings for ASA 150 Flanges

This article explains both the pressure class and temperature ratings for ASA 150 flanges, as well as how to select the right one for your needs.

Pressure Class

First, let’s take a look at the pressure class. The pressure class is the maximum allowable working pressure (MAWP) of a flange.

This rating is specified in pounds per square inch (psi), and it indicates the amount of pressure that the flange can withstand without failure.

Temperature Ratings

The temperature rating is also important as it specifies the range of temperatures that a flange can withstand. In most cases, this rating is expressed as an upper and lower limit in degrees Fahrenheit.

Flanges are constructed from different types of materials to suit varying applications. Each material has its pressure class and temperature ratings as listed below:

ASA 150

- Pressure Class: 150 to 2500 psi

- Temperature Rating: –29°C (-20°F) to 427°C (800°F)

ASTM A182 F304/304L and 316/316L

- Pressure Class: 150 to 1500 psi

- Temperature Rating: -65°C (-85°F) to 427°C (800°F)

Now that you know what the pressure class and temperature ratings are, how do you select the right one for your needs? The answer depends on the application. If you’re unsure which rating to choose, contact us at Oflange for assistance.

9. 7 Tips on How To Maintain ASA 150 Flange

Maintaining an ASA 150 flange is not as difficult as it may seem. However, there are some key things to remember to keep the flange functioning properly. Here are a few tips:

#1 Keep the Flange Clean

Always make sure the flange is clean and free of debris before use. Make sure to regularly clean the flange and its mating surface to prevent any buildup of dirt, debris, or oil.

#2 Inspect the Flange Regularly

Check for any signs of damage or wear, and address any issues as soon as possible.

#3 Apply a Sealant

A sealant can help to create a watertight seal between the flange and mating surface.

#4 Use the Right Tools

Make sure to use the right tools when tightening or loosening the flange, as this can help to avoid damage.

#5 Lubricate the Flanges

Apply a light coat of lubricant to the gasket and mating surfaces before assembly. This will help ensure a tight seal.

#6 Do Not Overtighten Screws and Bolts

Do not over-tighten the bolts or screws when securing the flange. This can cause damage and may lead to leakage.

#7 Periodically Check the Condition of the Parts

Periodically check the bolts and screws for tightness, and make sure all gaskets and seals are in good condition.

These are just a few tips on how to maintain an ASA 150 flange. For more information, be sure to contact us at Oflange.

By following these tips, you can help ensure that your flange remains in good condition and continues to function properly. Thanks for reading!

10. Potential Problems With Using an ASA 150 Flange

An ASA 150 flange is a type of flange that is commonly used in the piping industry. It is made of cast iron and is available in a variety of sizes.

The flange has several potential problems that can occur when it is used in certain applications. Some of these problems include:

- Leaking

- Damage to the flange

- Damage to the pipe

- Improper installation

- Improper use as a safety device

In some cases, these problems can be prevented by careful maintenance and inspection. However, there are also times when the problem may not be able to be resolved until after the damage has already occurred.

For example: leaking around an ASA 150 flange from improper installation of gaskets or O rings is very difficult to fix without having to remove the flange.

If you are considering using an ASA 150 flange order in your next project, it is important to be aware of these potential problems and take steps to avoid them.

If you have any questions about using a flange or need assistance with installation or maintenance, please contact us today at Oflange. We would be happy to help you get the most out of your flange.

To know more about the different classes of the flange, watch this video.

11. Conclusion

If you’re looking for a high-quality ASA 150 flange, then contact us today at Oflange.

We have years of experience in the piping industry, and we can help you find the perfect flange for your system. We guarantee that you won’t be disappointed with our products or services. Thanks for reading!