PRODUCT FEATURES

Carbon Steel Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

Carbon Steel Flange

Carbon steel flange is used in a variety of industries, such as automotive, construction, manufacturing, and oil & gas.

Carbon steel pipe flanges are versatile because they can be manufactured with both male and female ends. They are also durable due to their strength and resistance to corrosion.

Furthermore, the material is environmentally-friendly because it can be recycled when it becomes unusable in its current application.

Table of contents

1. Carbon Steel Flange Definition and What Does It Do

A carbon steel flange is a type of fitting that is used to connect two pieces of pipe. It is made from carbon steel, which makes it strong and durable.

The flange has a hole in the middle that allows it to be attached to the pipes, and it also has a series of bolts around the edge that hold it in place.

Carbon steel flanges can be found in a variety of shapes and sizes, and carbon fiber flanges are used to attach carbon fiber piping.

Carbon steel flanges can also be known as:

- Carbon Flanges

- Carbon Steel Blind Flange

- CS Flanges

- SA105N Flange

- Carbon Steel Flange HS Code

Carbon steel flanges are used to connect carbon fiber piping, so carbon steel flanges are fitted between the carbon fiber tubing and the carbon steel pipe.

They are also used on installing some carbon steel flange pressure ratings. The carbon steel material can be either threaded carbon steel flanges or welded carbon steel flanges.

Carbon fiber tubing is made from carbon fibers that are wound together to create a sturdy pipe. It is used in many types of manufacturing, especially in the construction industry.

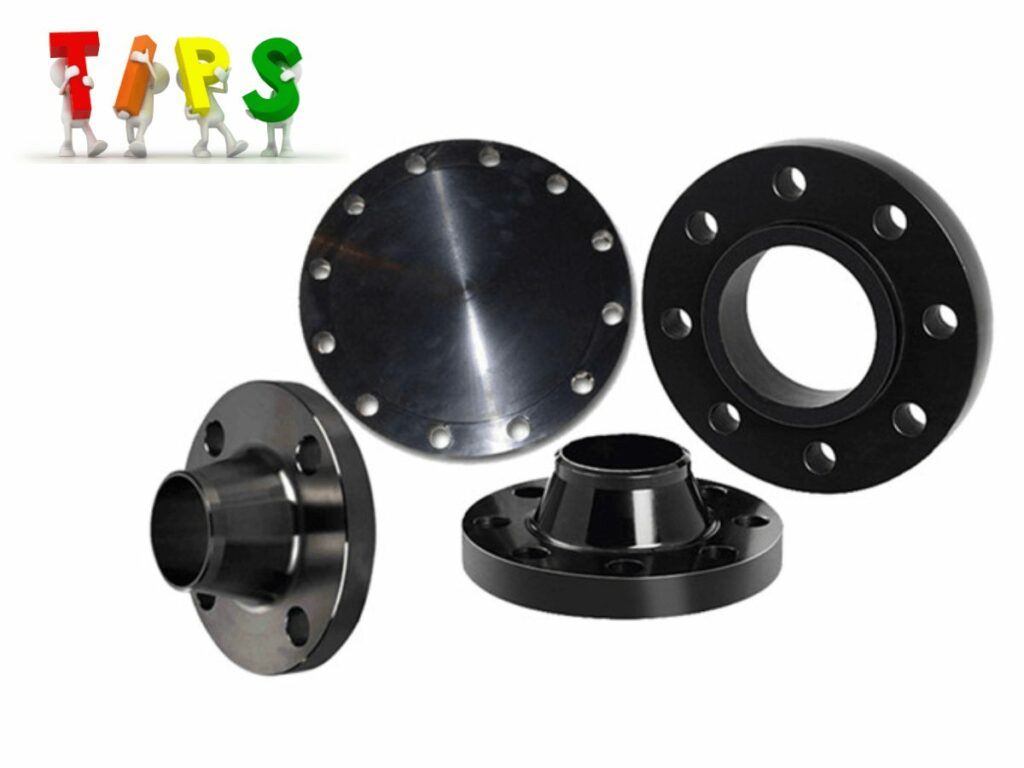

2. Types of Carbon Steel Flange and Their Uses

There are different types of carbon steel flange, each with its specific use. Some of the more common types include:

| 1 | Blind Carbon Steel Flange |

| 2 | Socket Carbon Steel Flange |

| 3 | Slip Carbon Steel Flange |

| 4 | Lap Carbon Steel Flange |

Blind Carbon Steel Flange

A blind carbon steel flange is used to close off the end of a pipe. It has a hole in the center that is larger than the diameter of the pipe and does not have any ports for connection.

Blind carbon steel flanges are usually welded to carbon steel piping to provide a fluid-tight seal.

Blind carbon steel flange weights end are often capped to prevent contaminants from entering the carbon steel pipe through the open end of the carbon steel flange dimensions.

Socket Carbon Steel Flange

A socket carbon steel flange is used to connect two pieces of water pipes. It has one port on each side that is threaded, and screws into the corresponding ports on the carbon steel flanges dimensions it is connecting.

The carbon steel flange has a raised lip around the outside edge of the flange, where it is attached to the pipes.

The carbon steel flange uses gaskets for sealing purposes. The carbon steel pipe flange dimensions come in different sizes. It also comes in different carbon steel flanges pressure and temperature ratings.

A Socket carbon steel flange rating is not interchangeable with other types of socket carbon steel or socket weld carbon steel flanges.

Slip Carbon Steel Flange

A slip carbon steel flange is used to connect two pieces of electrical pipes. It has one port on each side and is slipped onto the ends of the pipe.

Depending on the carbon steel flange rating like the ANSI flange ratings carbon steel, these pipes may be disjointed or welded.

A slip carbon steel flange can be used for a variety of purposes, including connecting pipes to equipment or building structures.

Lap Carbon Steel Flange

A lap carbon steel flange is often used to connect two pieces of PVC pipe. The flanges attach over each other so that each port lines up with the corresponding port on the other piece of pipe. Lap carbon steel flanges are not threaded.

3. Installation Process of Carbon Steel Flange

Installing a carbon steel flange can be a daunting task, but with the right tools and knowledge, it can be done relatively easily.

Step#1 Measure the Dimensions of the Pipe

The first step is to measure the thickness of the pipe that the flange will be installed on. This can be done with a caliper or ruler.

Step#2 Drill a Hole and Fit the Flange into the Pipe

Once the thickness is known, a hole must be drilled in the pipe that is the same size as the flange. Be sure to use a drill bit that is slightly smaller than the flange itself, so that the flange will fit snugly in the hole.

Step#3 Loosen the Nut on the Flange

After drilling the hole, use a pipe wrench to loosen the nut on the flange. Be sure to use caution, as carbon steel flanges can be very heavy and therefore can cause injury if dropped.

Step#4 Slide the Flange over the Pipe

The carbon steel flange must then be slid over the pipe and into the hole that has already been drilled out. If necessary, a mallet can be used to tap the carbon steel flange into place. Make sure not to damage the carbon steel flange with the mallet, as it is easy to do.

Step#5 Tighten the Nut

Once the carbon steel flange is in place, tighten the nut with a pipe wrench and use a crescent wrench to tighten any other nuts on the carbon steel flange.

The carbon steel flange is now installed and ready for use! Be sure to wear work gloves when using carbon steel flanges so they do not cause injury.

If you want to know more about the installation of flanges, watch this video;

4. Common Problems With Carbon Steel Flange and How to Solve Them

There can be several problems that can arise with carbon steel flanges, including:

Leaks

One of the most common problems with carbon steel cast iron flanges is leakage. This can be caused by several factors, including improper installation, use of the wrong sealant, and damage to the flange.

Sealing the threaded flange with minimum yield strength sealant will usually prevent leaks as long as the proper pressure class is observed.

Corrosion

Carbon steel blind flanges are susceptible to corrosion, especially in areas where there is saltwater or other corrosive elements present.

For carbon steel flanges to work properly, they need to be used in the proper environment and with proper installation procedures.

If a socket weld flange has to be used in a corrosive environment, it should be coated with ANSI flanges approved anti-corrosion paint. ANSI provides further guidelines for the heat treatment and chemical composition of the A105 Carbon Steel flange.

Warping

If carbon steel flanges are not properly cooled after being heated, they can warp and become unusable.

To avoid warping, the welding neck flange must be installed correctly and cooled properly after heating. The alloy element of the weld neck flange should also be taken into account.

The specified carbon maximum or the carbon content of the lap joint flange should be installed in the pressure systems so that the proper cooling technique can be used.

Cracking

Carbon steel flanges can also crack if they are subjected to too much stress. Always follow the carbon steel flange weight chart provided by your carbon steel flange manufacturer.

Joint flanges only work properly within a set tensile strength limit. If these common standards limits are exceeded due to high pressure, higher temperature service, or both, then cracking of the neck flanges is almost inevitable.

These carbon steel flange problems can largely be solved simply by following instructions, working with carbon steel flanges that are appropriate for the work environment, and using carbon steel flanges properly.

Contact us at Oflange for any questions regarding flanges.

5. Proper Carbon Steel Flange Maintenance

Carbon steel flanges are an important component in many industrial and commercial settings. Proper maintenance of these flanges is critical to ensure their long-term functionality and safety. Here are some tips for maintaining carbon steel flanges:

Tighten Bolts and Nuts Properly

Make sure that all bolts and nuts are tightened properly. A loose flange can cause serious accidents.

Inspect the Gaskets Regularly

Inspect the gaskets regularly for signs of wear and tear. A damaged gasket can lead to leakage and other problems.

Keep the Workplace Clean

Keep the area around the flange clean and free of debris. This will help prevent corrosion and other damage.

Use Temperature Appropriate Materials

If the flange is exposed to high temperatures or corrosive materials, coat it with a protective coating to protect it from damage.

Apply Protective Coating

Carbon steel flanges tend to rust and corrode over time, especially in humid or moist conditions. If they are stored outside, make sure they get a proper coat of paint or other protective coatings at the beginning of each season.

6. Carbon Steel Flange Average Cost

The carbon steel blind flange price list average cost can vary depending on the size and type of carbon steel flange. Generally, the carbon steel flange price list range from US$10 to US$200.

7. Carbon Steel Flange Manufacturer

There are various carbon steel flange manufacturer companies. Some of the more notable ones include Oflange, Swagelok, and Victaulic.

Carbon steel flange manufacturers offer carbon steel flanges in different shapes and materials.

Oflange

Oflange is a global manufacturer of pipe flanges and has been in business for several years.

Oflange provides innovative and high-quality products for use in applications such as pipeline systems, oil wells, gas processing plants, and refineries.

Swagelok

Carbon steel flanged couplings manufactured by Carbon Steel Flange Manufacturer Swagelok can come with male and female flanges. They also have male flange face to female flange face.

Victaulic

Carbon Steel Flange Manufacturer Victaulic provides carbon steel buttweld couplings that range from carbon steel buttweld couplings to carbon steel socket welding couplings.

8. 3 Tips to Choose the Right Carbon Steel Flange for Your Needs

Carbon Steel Flanges have a variety of important uses in the industry. There are several things to consider when choosing carbon steel flanges.

#1 Consider the Pressure and Temperature Ratings

When choosing a carbon steel flange, you will need to consider the pressure and temperature requirements of your application.

#2 Select the Proper Size and Type of Flanges

Be sure to choose carbon steel flanges that have the proper type and size for your needs.

#3 Consult with an Expert

Make sure to consult with a qualified engineer to ensure that you choose the right carbon steel flange for your needs.

9. Conclusion

Carbon steel flanges are used in many industries, such as automotive, construction, manufacturing, and oil & gas.

If you’re looking for a carbon steel flange that will last through years of use without corroding or rusting then look no further than us at Oflange!

We offer high-quality products at affordable prices to ensure your satisfaction. You won’t find another company like us on the market today! Click here to check out our selection of carbon steel pipe flanges now!