PRODUCT FEATURES

Stainless Steel 304l Flanges Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

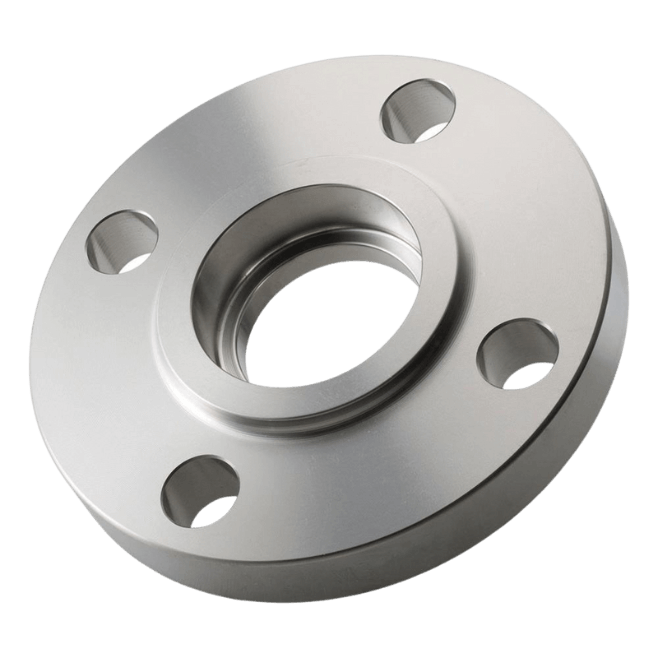

Stainless Steel 304L Flanges

Stainless Steel 304L Flanges are a popular choice for many different applications. They are strong, durable, and resistant to corrosion. Stainless Steel 304L Flanges are also available in a variety of sizes and styles.

These flanges are commonly used in industrial applications including boilers, heat exchangers, pressure vessels, and piping systems. They can also be used in construction projects such as bridges and tunnels. They can be welded or bolted in place. They are also available in both standard and custom designs.

Table of contents

1. Stainless Steel 304L Flanges Definition and Its Uses

Stainless Steel 304L flanges are a type of flange that is made from the Stainless Steel 304L alloy. This type of flange is often used in applications where high corrosion resistance is required. Stainless Steel 304L flanges are also very strong and can withstand a high amount of pressure.

The specifications for Stainless Steel 304L flanges can vary depending on the application. However, in general, stainless steel flanges have a thickness of between 3 and 8 millimeters and a diameter of from 50 to 600 millimeters.

The uses of Stainless Steel 304L flanges vary but can include applications in the chemical, food, and beverage industries. Stainless Steel 304L flanges are also commonly used to construct pipelines and other piping systems.

2. Stainless Steel 304L Flanges Composition

Stainless steel 304L flanges are made of a particular type of alloy. This alloy is a mix of various metals. Aside from alloy, Stainless steel 304L flanges also contain chromium, nickel, and carbon steel.

Alloy Steel

Stainless steel 304L flanges are made of alloy steel. This type of metal is a blend of metals that includes chromium, nickel, and carbon steel. It is known for its high corrosion resistance and strength.

Chromium

Chromium is a chemical element that is found in Stainless steel 304L flanges. It helps to protect the alloy from corrosion and makes it resistant to most common chemicals.

Nickel

Nickel is another chemical element that is found in Stainless steel 304L flanges. It helps to improve the strength and durability of the alloy.

Carbon Steel

Carbon steel is a type of metal that is found in Stainless steel 304L flanges. It helps to add strength to the alloy and makes it resistant to wear and tear.

3. The Manufacturing Process of Stainless Steel 304L Flanges

The Stainless Steel 304L flanges are made through a process that involves the use of heavy machinery. Below is the step-by-step process on how Stainless Steel 304L flanges are made:

Step #1 Cut the Steel and Shape It

The first step in the process is to take the raw steel and shape it into the desired form. This is done through the use of a rolling mill. The rolling mill will press the steel against a rotating die to create the desired thickness and shape.

Step #2 Weld the Steel

After the steel has been shaped, it is then sent to the welding department. Here, the steel is welded together to create the flange. The welding is done using a resistance welding process. This is a process that uses heat to join the two pieces of steel together.

Step #3 Polish the Flange

After the welding is done, the flange is then sent to the polishing department. Here, it is polished to a mirror finish. This is done by using a series of rotating brushes that will remove any imperfections on the surface.

Step #4 Inspect and Pack the Flange

The final step in the process is to inspect and pack the Stainless Steel 304L Flange. This is done by using a series of optical and manual inspection techniques. The flanges are then packed in a box and shipped to the customer.

4. The Different Class of Stainless Steel 304L Flanges

Stainless steel 304L flanges are considered a different class of Stainless steel 304L flanges. They are made to withstand high pressure and have better resistance to corrosion. Stainless steel blind flanges are made of higher quality material and are more durable than other types of Stainless steel 304L flanges.

Below are the different classifications of Stainless steel 304L flanges:

| 202 Stainless Steel Flange | More resistant to rust and has better mechanical properties |

| 304 Stainless Steel Flange | It has good corrosion resistance and toughness |

| 316 Stainless Steel Flange | More resistant to pitting and crevice corrosion |

| 321 Stainless Steel Flange | Better corrosion resistance and higher heat resistance |

| 347 Stainless Steel Flange | Good resistance to heat and mechanical properties |

| 904l Stainless Steel Flange | Best corrosion resistance of all the Stainless Steel 304L flanges |

| Pn16 Stainless Steel Flange | Good corrosion resistance and toughness |

202 Stainless Steel Flange

This is a standard Stainless steel grade that is not as corrosion resistant as the 304 Stainless steel flange. However, it is more resistant to rust and has better mechanical properties. This flange is commonly used in construction and architectural applications.

304 Stainless Steel Flange

It is a standard stainless steel grade. It has good corrosion resistance and toughness. This flange is commonly used in chemical and petrochemical industries.

316 Stainless Steel Flange

It is a stainless steel grade with better corrosion resistance than the 304 Stainless steel flange. It is also more resistant to pitting and crevice corrosion. This flange is commonly used in food and beverage processing, pharmaceuticals, and other sanitary applications.

321 Stainless Steel Flange

It is a stainless steel grade with better corrosion resistance and higher heat resistance than the 304 Stainless steel flange. This flange is commonly used in chemical and petrochemical industries, as well as high-temperature applications.

347 Stainless Steel Flange

It is a stainless steel grade with the best corrosion resistance of all the Stainless Steel 304L flanges. It also has good resistance to heat and mechanical properties. This flange is commonly used in chemical and petrochemical industries, as well as high-temperature applications.

904l Stainless Steel Flange

It is a stainless steel grade with the best corrosion resistance of all the Stainless Steel 304L flanges. It also has good resistance to heat and mechanical properties. This flange is commonly used in chemical and petrochemical industries, as well as high-temperature applications.

Pn16 Stainless Steel Flange

This is a Stainless steel 304L flange with a pressure rating of 16 bar. It has good corrosion resistance and toughness. This flange is commonly used in chemical and petrochemical industries, as well as high-pressure applications.

Each of these different classes of Stainless Steel 304L flanges has its own unique benefits and drawbacks. It is important to understand the differences between them before selecting the right Stainless steel 304L flange for your needs.

If you want to know more about Stainless Steel 304L flanges or need help selecting the right one for your application, please contact us at Oflange today. We would be happy to help you find the perfect Stainless steel 304L flange for your needs.

5. Different Size of Stainless Steel 304L Flanges

Stainless Steel 304L flanges are available in different sizes. This allows you to find the perfect size for your needs. The different sizes also provide you with a variety of options to choose from. Whether you need a small or large flange, there is sure to be a size that will fit your needs.

Below are the different sizes that are available for Stainless Steel 304L flanges:

- 1 inch stainless steel flange

- 2 inch stainless steel flange

- 3 inch stainless steel flange

- 4 inch stainless steel flange

The size of the flange you need will depend on the type of project you are working on and the type of pipe you are using. If you are not sure which size to choose, talking to a professional such as Oflange is always a good idea. They can help you determine which size is best for your needs.

If you want to know how to measure a flange, watch this video.

6. Advantages and Disadvantages of Stainless Steel 304L Flanges

When it comes to Stainless Steel 304L flanges, there are some advantages and disadvantages that should be considered. Stainless steel is a great material for flanges because it is strong, corrosion-resistant, and durable.

The advantages of Stainless Steel 304L flanges include:

- They are strong and durable because of the stainless steel material.

- They are corrosion resistant and can withstand a variety of environments.

- Stainless steel flanges can last a long time with proper care.

- They are easy to clean and maintain.

However, Stainless Steel 304L flanges also have some disadvantages, including:

- They can be expensive because of the stainless steel material.

- They can be difficult to weld.

- They can be susceptible to rusting if not properly maintained.

Overall, Stainless Steel 304 Flanges are a versatile and durable option for flanges and offer a number of advantages over other materials. When choosing flanges, it is important to consider all the pros and cons of each material to ensure you select the best option for your needs.

7. Applications of Stainless Steel 304L Flanges in Various Industries

Stainless Steel 304L flanges find a lot of applications in various industries. Some of the most important ones are mentioned below:

Food and Beverage Industry

Stainless Steel 304L flanges are often used in the food and beverage industry because they are non-reactive and corrosion-resistant. This makes them ideal for use in piping and tubing systems that come into contact with food or beverages.

Chemical Industry

Stainless Steel 304L flanges also find a lot of applications in the chemical industry. They are often used in systems that handle corrosive fluids and gases.

Oil and Gas Industry

Stainless Steel 304L flanges are commonly used in the oil and gas industry to handle high-pressure fluids and gases. They are also used in oil refineries and gas processing plants.

Marine Industry

Stainless Steel 304L flanges are often used in the marine industry to handle seawater and other corrosive fluids.

So, as you can see, stainless steel 304L flanges have a wide range of applications in various industries. They are reliable and durable and can handle a wide range of fluids and gases. If you need a quality flange for your industrial application, stainless steel 304L is a good option to consider.

8. Stainless Steel 304L Flanges Average Cost

Stainless Steel 304L flanges are an important component in many industrial and commercial applications. They are often used in high-pressure and high-temperature applications and can be found in a variety of industries, including oil and gas, chemical processing, and power generation.

SS 304L price can vary depending on the size and type of flange, as well as the supplier. However, the cost is typically between $50 and $100 per flange.

When shopping for Stainless Steel 304L flanges, it is important to consider the size, type, and grade of the flange. It is also important to ensure that the supplier is qualified and experienced in supplying them.

If you want to buy Stainless Steel 304L flanges, contact us at Oflange today. We can help you find the right flanges for your application and provide you with a competitive quote.

9. Where to Purchase Stainless Steel 304L Flanges in Bulk

When looking for a supplier of Stainless Steel 304L flanges, it is important to find one that can provide you with quality products in bulk quantities. Stainless steel flanges are an important component of many industrial and commercial applications, so it’s important to find a supplier that can meet your needs.

Online Marketplace

One of the best places to find quality Stainless Steel 304L flanges is through an online marketplace. These marketplaces are designed to connect buyers and sellers of all types of products, including stainless steel flanges.

Local Supplier

If you’re looking for a local supplier of Stainless Steel 304L flanges, your best bet is to search for industrial supply stores in your area. These stores will carry a variety of stainless steel flanges and other industrial supplies such as socket weld flange, joint flange, and neck flange, so you can find what you need all in one place.

Engineering Supplier

If you’re looking for a supplier of Stainless Steel 304L flanges that specializes in engineering supplies, your best bet is to search for engineering suppliers online. These suppliers will have a wide variety of stainless steel flanges and other engineering supplies, so you can find what you need all in one place.

Manufacturers

If you’re looking for a supplier of Stainless Steel 304L flanges that is also a manufacturer, your best bet is to search for manufacturers online. By doing so, you’ll have access to both the products and the pricing information for Stainless Steel 304L flanges.

You may also be able to find manufacturers such as Oflange that will allow you to order Stainless Steel 304L flanges in custom sizes and shapes.

Oflange is a global manufacturer of pipe flanges and has been in business for several years. We provide innovative and high-quality products for use in applications such as pipeline systems, oil wells, gas processing plants, and refineries.

Our mission statement is to manufacture high-quality, durable, and affordable products that will serve the needs of their customers.

10. 3 Tips to Select the Right Stainless Steel 304L Flanges for Your Needs

When selecting Stainless Steel 304L flanges, it is important to consider the following factors:

#1 The Type of Material

Identify the type of material that will be used in the flange. Stainless steel 304L is a common choice for many industrial applications because it is corrosion-resistant and has a high melting point.

#2 The Size and Shape of the Flange

The size and shape of the flange must match the needs of the application. Stainless Steel 304L flanges are available in a variety of sizes and shapes to suit many different applications.

#3 The Pressure and Temperature Requirements

The pressure and temperature requirements of the application must also be considered when selecting Stainless Steel 304L flanges. Stainless steel 304L is capable of withstanding high pressures and temperatures, making it a good choice for many industrial applications.

When selecting Stainless Steel 304L flanges, it is important to consider the type of material, the size and shape of the flange, and the pressure and temperature requirements. Stainless steel 304L is a common choice for many industrial applications because it is corrosion-resistant and has a high melting point.

11. Final Words

Stainless Steel 304L flanges are the perfect choice to meet your needs. They’re made in many different grades and specifications to ensure they fit your application perfectly. You can trust that our Stainless Steel 304L flanges will last a lifetime, no matter what environment they’re used in.

Our Stainless Steel 304L flanges are designed with you in mind. Whether you need them for commercial or industrial use, our Stainless Steel 304L flanges are a perfect choice. Contact us at Oflange to learn more.