PRODUCT FEATURES

Tongue and Groove Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

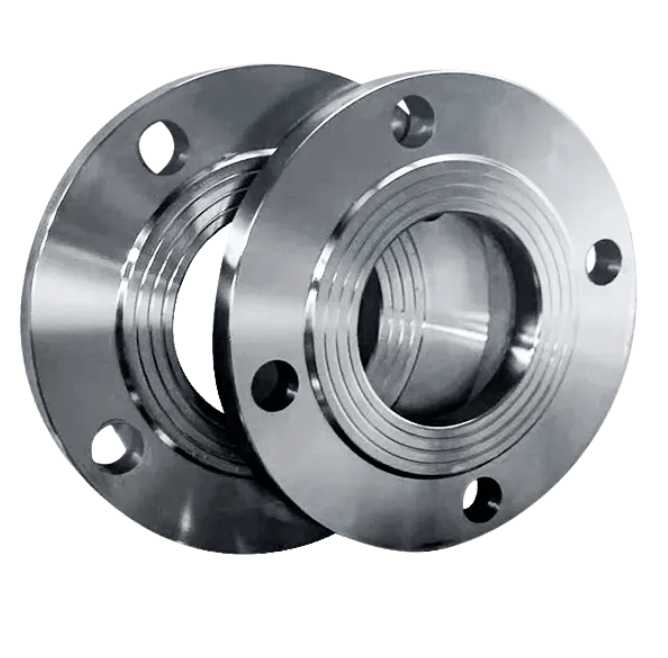

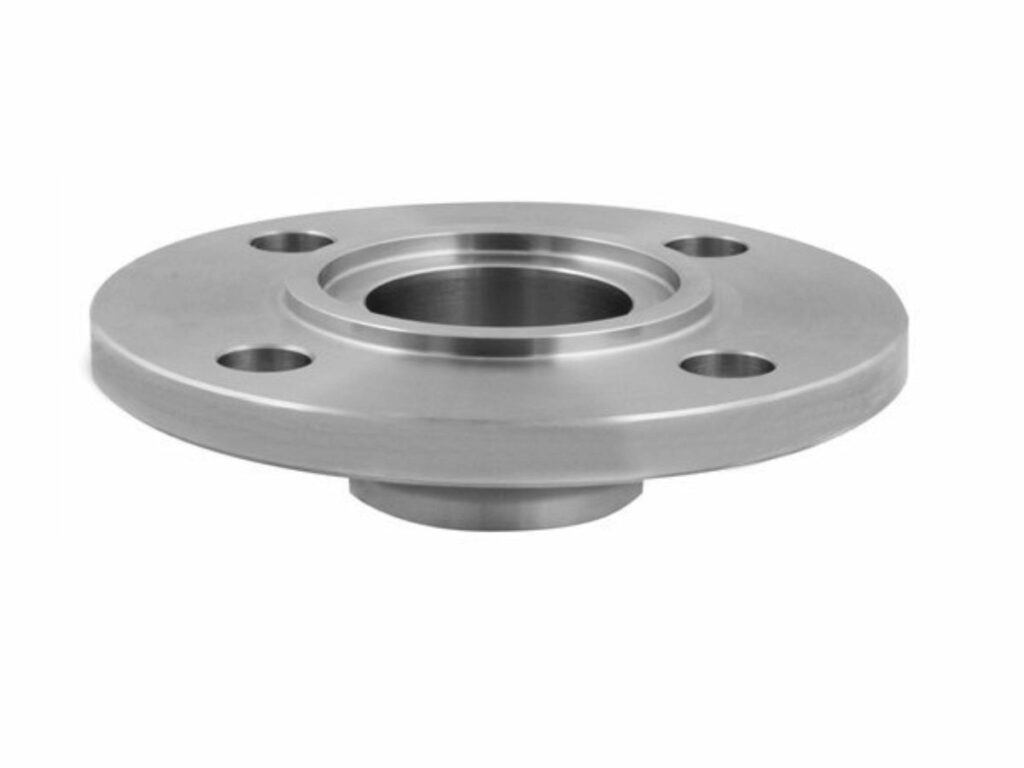

Tongue and Groove Flange

The tongue and groove flange is a type of flange that features a tongue and groove design. This design allows the flanges to be joined together easily and securely. The tongue and groove flange is often used in applications where a strong, leak-proof joint is required.

The tongue and groove flange is available in a variety of sizes and materials, making it a versatile option for many different applications. It is also relatively easy to install, making it a popular choice for many users.

Table of contents

1. Benefits of Tongue and Groove Flange Over Other Types of Flange

There are a number of reasons to prefer tongue and groove flanges over other types. Some of the key benefits include:

Greater Strength and Stability

The tongue and groove connection is much more secure than a standard flange, which means there is less chance of the connection coming apart or leaking. This makes the tongue groove flange ideal for high-pressure or high-stress applications.

More accurate Alignment

The tongue & groove flange is much more likely to be perfectly aligned with each other, which results in a tighter seal and less leakage.

Easier Installation

Tongue and groove flanges can be installed quickly and easily, without the need for any special tools or equipment.

Reduced Wear and Tear

The tongue groove flanges connection minimizes the amount of wear and tear on both the flange and the pipe, which helps to extend the life of both components.

Greater Versatility

Tongue and groove flanges can be used in a variety of applications, making them a versatile choice for many different projects.

When choosing a flange type, groove flange tongue should always be at the top of the list. With their many benefits, they are sure to provide a secure connection and lasting performance in any application.

2. How Is a Tongue and Groove Flange Connection Made

The steel tongue groove flanges connection is very strong and can withstand high pressures. It is used in many applications, such as piping, valves, and pumps.

Here’s how the tongue and groove connection is made:

The Tongue Is Welded to the Pipe

The tongue is welded to the pipe at the desired location. This can be done with a variety of welding methods.

The Groove Is Cut Into the Flange

The groove is then cut into the flange using a machining process. This ensures that the tongue and groove fit together perfectly.

The Flange Is Assembled to the Pipe

Once the tongue and groove are in place, the flange is then assembled to the pipe. This is done by welding the flange to the pipe or by bolting it in place.

If you are looking for a strong and reliable connection, the tongue and groove flange connection is a great option. Contact us today at Oflange to learn more about this connection type or to order tongue and groove flanges for your next project.

3. Dimensions of a Tongue and Groove Flange

The dimensions of a tongue and groove flange depend on the size of the pipe and the material of the flange. The width of the tongue should be slightly less than the width of the groove to ensure a tight fit.

The thickness of the steel tongue and groove should be equal to the thickness of the pipe. The height of the tongue should be at least one-half the width of the groove. The dimensions of a tongue and groove flange also depend on the type of flange.

The average tongue and groove flange dimensions in mm are as follows:

| Width of the tongue | 12mm |

| Width of groove | 18mm |

| The thickness of tongue and groove | 0.75mm |

| Height of tongue | 12mm |

The dimensions for a tongue and groove flange in inches are as follows:

| Tongue width | 0.875 inches |

| Tongue thickness | 0.125 inches |

| Tongue height | 0.438 inches |

| Groove width | 0.875 inches |

| Groove depth | 0.563 inches |

| Pipe diameter | up to 24 inches |

| Flange thickness | 0.187 – 0.437 inches |

| Welding neck tongue width | 0.968 inches |

| Slip-on tongue width | 0.875 inches |

The dimensions of a stainless steel tongue and groove flange are important for ensuring a tight seal between the pipe and the flange. If the dimensions are not correct, the pipe may leak or the flange may come loose.

It is important to consult with a manufacturer such as Oflange to determine the correct dimensions for your application.

4. Applications for a Tongue and Groove Flange Connection Type

The tongue and groove flange connection type has a variety of applications. Some of the tongue and groove flange applications include the following:

Furniture Assembly

Tongue and groove pipe flanges are commonly used to assemble furniture. The tongue and groove connection type is strong and reliable, making it a popular choice for this application.

Cabinet Making

Tongue and groove flanges are also popular in cabinet making. In this application, the tongue and groove connection type is often used to create a strong joint between two pieces of wood.

Joining Plywood

Tongue and groove flanges can also be used to join plywood. In this application, the tongue and groove connection type is used to create a watertight seal between two pieces of plywood.

Boat Building

Tongue and groove flanges are also commonly used in boat building. In this application, the tongue and groove connection type is often used to create a watertight seal between two pieces of wood.

Carpentry

Tongue and groove flanges are also popular in carpentry. In this application, the tongue and groove connection type is often used to create a strong joint between two pieces of wood.

Joinery

The tongue and groove joint flange is also popular in joinery. In this application, the tongue and groove connection type is often used to create a strong joint between two pieces of wood.

Construction

Tongue and groove flanges are also popular in construction. In this application, the tongue and groove connection type is often used to create a watertight seal between two pieces of wood.

The t&g flange connection type is a versatile way to connect two pieces of material. It can be used in a variety of applications, making it an essential tool for any craftsman or DIYer. With its simple design, it is easy to use and provides a strong connection between two pieces of material.

5. Limitations of Using a Tongue and Groove Flange Connection

The tongue and groove flange connection offers several advantages over other types of connections. It is strong and stable, and it is also relatively easy to use. However, there are some limitations to using this type of connection:

Can Be Difficult To Use in Tight Spaces

The tongue and groove connection relies on a tight fit between the two pieces to be effective. This can make it difficult to use in tight spaces where there is not enough room to fit the two pieces together properly.

Might Not Be as Stable as Other Connections

The tongue and groove flange connection is relatively stable, but it might not be as stable as other connections. It is important to test the stability of this connection before using it in a critical application.

Can Be Damaged if Not Properly Installed

The tongue and groove flange connection can be damaged if not properly installed. It is important to follow the manufacturer’s instructions carefully when installing this type of connection.

Despite these limitations, the tongue and groove flange connection is a strong and reliable connection that can be used in a variety of applications. When used correctly, it can provide a secure and stable connection between two pieces of metal.

6. Cost of Tongue and Groove Flange

The cost of tongue and groove flange can vary depending on the size and thickness of the metal. It can also depend on the type of metal used and the tongue and groove flange gasket. They are most commonly made out of steel, aluminum, or brass.

The cost can also depend on the finish of the tongue and groove flange. There are a variety of finishes that can be applied to tongue and groove flange, such as galvanized, black oxide, chrome, or nickel.

The average cost of a tongue and groove flange is around $0.50 to $0.70 per piece. However, the cost can go up depending on the size and thickness of the metal, as well as the finish that is applied.

If you want an exact price for tongue and groove flange, contact us at Oflange and we would be happy to give you a quote.

7. Tongue and Groove Flange Standard

The tongue and groove flange standard is an industry-standard specification that covers the design and manufacture of tongue and groove flanges. This standard is published by the American Society of Mechanical Engineers (ASME).

It specifies the tongue and groove flange dimensions and tolerances for tongue and groove flanges, as well as the requirements for manufacturing these flanges. You can refer to this tongue and groove flange dimensions pdf file for more information about the dimensions chart, gasket, gasket dimensions, and other flanges.

The tongue and groove flange standard is widely used in the piping and tubing industries. It helps to ensure that tongue and groove flanges are manufactured to a high-quality standard, and it helps to ensure that they meet the needs of these industries.

8. 5 Tips for Maintaining Tongue and Groove Flange Connection

There are a few tips to remember when it comes to maintaining tongue and groove flange connection:

#1 Always Use the Same Type of Wood for the Tongue and Groove

When making a tongue and groove joint, it’s important to use the same type of wood for both the tongue and the groove. This will ensure a tight fit and keep your joints looking good.

#2 Use Proper Joining Techniques

There are different techniques you can use when joining tongue and groove boards: butt joints, rabbeted joints, or dovetail joints. Choose the one that will give you the strongest joint and use good-quality wood glue.

#3 Make Sure the Tongue is of Proper Length

The tongue should be just long enough to fit into the groove but not too long or it will stick out and be visible. Trim it to size if necessary.

#4 Match Grain Patterns

If possible, try to match the grain patterns of the tongue and groove boards as closely as possible. This will help disguise any joints and give your project a more polished look.

#5 Apply a Finish

Once your tongue and groove joint is assembled, apply a finish to protect the wood and keep it looking good for years to come. A coat of polyurethane or varnish will do the trick.

By following these tips, you can ensure that your tongue and groove flange connections stay tight and look great for years to come. For more information on tongue and groove joints, contact us at Oflange.

If you want to know other types of the flange, watch this video.

9. Final Words

The tongue and groove flange is the perfect solution for your needs. It’s made from durable materials, so it won’t break or crack under pressure. And with its strong design, this flange will keep leaks at bay. You can trust our products to get the job done right!

We offer a wide range of sizes and styles to choose from, so we have something for every application. Our team is standing by to answer any questions you may have about our products or services – just contact our Oflange team today!