PRODUCT FEATURES

DN 65 Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

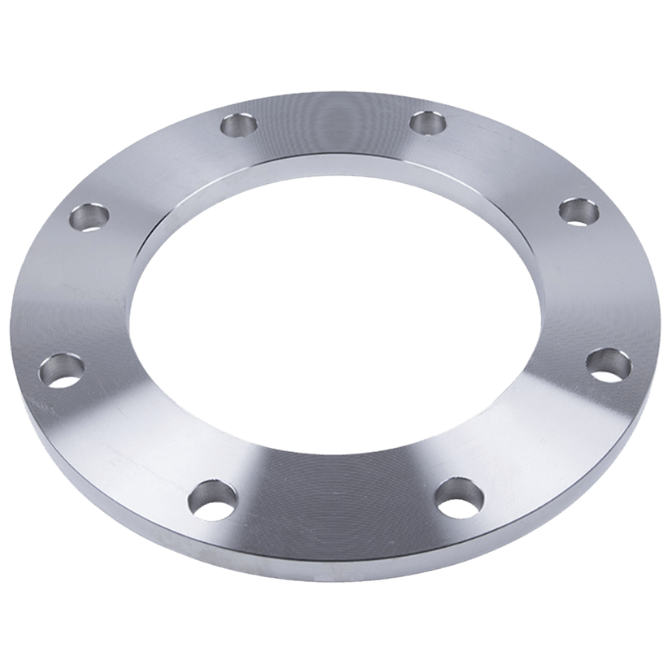

DN65 Flange

DN65 Flange is a high-quality flange that features superior control and durability. This product is ideal for commercial use, providing the best of both worlds in terms of functionality and value.

The Flange is available in both stainless steel and aluminum, as well as a variety of different materials for the adaptors. The flange can be used on its own or combined with other components from the DN65 series to create larger systems.

Table of contents

1. DN65 Flange Definition

DN65 flanges are fittings that are used to connect two sections of pipe. DN65 flanges come in a variety of different sizes and are made from a variety of different materials.

DN65 flanges are also available in several different designs, including threaded, weld neck, slip-on, and socket weld. Aluminium flanges are specified by their nominal diameter (DN) and their pressure class (AWWA).

The DN65 flange is a 65-millimeter nominal diameter flange that has a pressure class of 150. The DN65 flange is also available in several other standard classes, including 300, 400, 600, 900, and 1500.

DN65 flanges are manufactured from a variety of different materials, including cast iron, ductile iron, brass, stainless steel, and carbon steel. DN65 flanges are designed for a variety of different uses, including potable water systems, natural gas lines, and steam lines.

2. The Difference Between DN65 Flange Type and Other Flange Types

DN65 flange is a specific type of flange that is used for pipelines. It is a 65-millimeter flange, which is why it is called DN65. There are a few key differences between DN65 flange types and other flange types including:

- DN65 is a metric unit of length, while other flange types use the British Standard Unit System.

- DN65 flange types are typically smaller in size or flanges thicknesses vary slightly, making them easier to work with whereas DN50 and DN100 flange types are larger sizes.

- DN65 flanges are less expensive, other flanges are more expensive.

- DN65 flange types are easier to use, whereas DN50 and DN100 flange types require more work.

- DN65 flange types are typically used for small pipelines while DN50 and DN100 flange types are used for large pipelines.

- DN65 flange type is often designed with molded rubber gasket valves whereas DN50 and DN100 are not typically designed with molded rubber gasket valves.

- DN65 flange types are flat face flanges, whereas DN50 and DN100 are raised face flanges.

For these reasons, the DN65 flange is the most common flange type used in pipelines. It is much smaller than other types and can be installed without difficulty.

3. DN65 Flange Standards

DN65 flange standards are set by the American National Standards Institute (ANSI). These standards cover the design and manufacture of flanges up to DN65 in size. The standards help ensure that flanges thinner flange thickness meet a minimum level of quality and that they are interchangeable between manufacturers.

DN65 flanges are commonly used in water and wastewater applications, as well as in the oil and gas industry. DN65 ANSI standards have been developed by the American Society of Mechanical Engineers (ASME), a U.S.-based organization that sets standards for many products and (more…)

DN65 flange standards help ensure that DN65 ANSI flanges are designed, manufactured, inspected, and tested to the same specifications. DN65 neck flange standards ensure all DN65 ANSI flanges meet a minimum level of quality regardless of where they are manufactured or who manufactures them.

4. DN65 Flange Material

DN65 Flange Material is a type of pipe fitting that is commonly used in the plumbing and piping industries. It is made from a variety of materials, including:

Stainless Steel

DN65 Flange Material can also be made from stainless steel, which is a popular choice for many applications because it is strong and durable. Stainless steel is also rust and corrosion-resistant, which makes it a good choice for environments that are prone to these issues.

Carbon Steel

Carbon steel is also less expensive than stainless steel, making it a more economical option for some applications. However, carbon steel is not as rust and corrosion-resistant as stainless steel, so it may not be the best choice for environments that are prone to these issues.

Copper

Copper DN65 Flange Material is often used for water supply lines, as copper alloy flanges can naturally resist rust and corrosion. Copper DN65 Flange Material is also an excellent conductor of heat and electricity, so it may be a good choice for appliances that require these properties to operate effectively.

Alloy Steel

Alloy DN65 Flange Material is made from steel flanges that have been alloyed with nickel, chromium, manganese, and other metals. It contains many of the same properties as carbon steel DN65 Flange Material, but it also has increased corrosion resistance.

Ductile Iron Column

DN65 Flange Material is cast iron column or sintered iron flanges that have been treated to increase its strength and durability. It is an economical DN65 Flange Material choice, as it does not need to be painted or coated with other materials to resist rust andcorrosion.

Therefore, DN65 Flange Material can be made from several different materials, which makes DN65 Flange Material design and fabrication an exciting and versatile field.

5. DN65 Flange Dimensions

DN65 flange dimensions are important to know when you are working with piping systems. DN65 flanges are typically used in high-pressure piping systems due to their design and quality construction.

| Bore diameter | 65 millimeters |

| Bolt circle diameter | 95 millimeters |

| Thickness | 7 millimeters |

| Plate thickness | 0.3 millimeters |

| Width | 100 millimeters |

| Height | 38.1 millimeters |

DN65 Flange Dimensions are as follows:

- The DN65 flange has a bore diameter of 65 millimeters.

- The DN65 flange has a bolt circle diameter of 95 millimeters.

- The DN65 flange has a thickness of 7 millimeters.

- The DN65 flange has a plate thickness of 0.3 millimeters.

- The DN65 flange has a width of 100 millimeters.

- The DN65 flange has a height of 38.1 millimeters.

Therefore, DN65 PN16 flange dimensions, EN 1092 PN16 flange dimensions, and DN150 PN16 flange dimensions are very important factors to take into consideration when you are working on a DN65 piping system.

DN65 flanges are typically used in liquid and gas transfer lines due to their ability to be able to withstand high pressure.

6. DN65 Flange Manufacturing Process

A DN65 flange is a type of flange that has a diameter of 65 millimeters. It is used to connect pipes and tubes. The DN65 flange is manufactured in the following way:

Step#1 Material Preparing

To manufacture a DN65 flange, the first step is to prepare the material. The material needs to be cut to the correct size and then drilled to create the holes that will be used to attach the flange to the pipe or tube.

Step#2 Material Cutting

To cut the DN65 flange from a steel plate, take an iron plate and transfer the planned DN65 flange design onto it. Make sure that you use a grinder to make any dial-size corrections before you proceed with marking each cut line.

After all, lines are marked, join the lines together with either chalk or pencil. Now, cut using a jigsaw or a band saw.

Step#3 Heating the DN65 Flange

Heat DN65 flange to about 500 degrees Fahrenheit. Use a heat gun or a propane torch for heating the DN65 flange so it can be easily bent into shape. You can also use a welding machine or a gas forge to heat the DN65 flange.

Step#4 Forging DN65 Flange

After heating the DN65 flange, place it on an anvil and shape the DN65 flange into its desired shape. Use a hammer to create dents or indentations that will increase the DN65 flange’s surface area and make it stronger.

Step#5 Heat Treatment DN65 Flange

After shaping the DN65 flange, heat the DN65 flange to about 1000 degrees Fahrenheit and then allow it to cool down naturally without applying any external force. This process hardens the DN65 flange so it will be stronger than before.

Step#6 Machining DN65 Flange

To cut DN65 flange into a certain shape or size, use a lathe to bore DN65 flange. The DN65 flange needs to be turned and after the diameter has been reduced to about 3/8 of an inch, it can be easily drilled and shaped to make final adjustments before attaching the DN65 flange to the pipe or tube.

Step#7 Drilling DN65 Flange

If DN65 flange needs to be drilled, attach DN65 flange to a drill press with proper flange drillings equipment needed for DN65 flange. Drill holes in the DN65 flange that are slightly greater than half of the DN65 flange thickness.

Step#8 Final Inspection

DN65 flange is now ready for final inspection before it is packaged and shipped to the customer. The quality control department will check the DN65 flange for any defects or problems that may need to be corrected.

Once it is approved, the DN65 flange will be sealed in a plastic bag and placed in a cardboard box for shipping.

Therefore, the DN65 flange is manufactured in a multi-step process. Each step of the DN65 flange manufacturing process is completed by a different machine or tool.

7. The Benefits of DN65 Flange

DN65 Flange is a type of flange that is commonly used in the piping industry. It is made from forged steel and has a 65mm diameter. DN65 flanges are used to connect pipes and can be found in a variety of different sizes.

The benefits of using DN65 flanges include:

Strong and Durable

DN65 flanges are strong and durable, making them ideal for use in the piping industry. They can withstand high pressure and temperatures and are resistant to corrosion and rust.

Easy To Transport

DN65 flange is lightweight and has a compact design, which makes them easier to transport than other types of flanges. DN65 flanges are used to connect pipes that need to be transported across long distances.

Easy To Install

DN65 flanges are attached to the main pipeline using bolts and nuts, making them fast and simple to install. They are also used in pipelines that run through buildings or underground, so saving time when installing DN65 flanges is essential.

Can Be Used With a Variety of Different Materials

DN65 flanges are manufactured from steel, but they can be used with a variety of different materials, including wood, plastic, and even rubber. DN65 flanges can be used with a variety of different materials because they have pressure-tight seals and connectors designed to fit with DN65 flanges.

Flexible

DN65 flange is flexible and can be bent around tight corners. DN65 flange is ideal for use in pipelines that need to be bent around corners or in situations where space is limited. DN65 flange is easy to cut and can be adjusted as needed.

Overall, DN65 flanges have a wide range of benefits that make DN65 flange the ideal choice for use in the piping industry.

8. DN65 Flange Average Cost

DN65 flanges can be found in a variety of industries, including the petrochemical, oil and gas, and power generation industries. They are commonly used in high-pressure and high-temperature applications.

Because they are so versatile, DN65 flanges are in high demand, and the average cost can vary depending on the size and type of DN65 flange you need. In general, the cost of a DN65 flange will be between $10 and $25 per piece.

Larger orders may qualify for discounts, and smaller orders may incur additional fees. DN65 flanges can be purchased in a variety of ways, including online and offline.

It is important to check the DN65 flange average cost to ensure that one is getting the best deals available. For more information on DN65 flanges, and another flange sizing, contact a company like Oflange.

We offer DN65 flanges and a variety of other flange sizes with affordable price tags. Contact us today at Oflange to learn more about the DN65 flange average cost.

9. 5 Maintenance Tips for DN65 Flange

DN65 flanges are often used in high-pressure and high-temperature applications. To ensure optimal performance and extend the life of the flange, follow these maintenance tips:

#1 Clean Regularly

Regularly clean DN65 flange with a high-pressure washer. Accumulated dirt increases the risk of leaks and other problems.

#2 Replace Seals

Replace DN65 flange seals if they appear worn or damaged. The rubber material used should resist high temperatures and meet certain other specifications. DN65 flange seals are an inexpensive part of the DN65 flange system and can be easily replaced.

#3 Lubricate O-Rings

Lubricate DN65 flange O-rings periodically. This prevents damage from increased friction, reducing the risk of leaks and DN65 flange failure.

#4 Ensure Proper Mounting

Ensure DN65 flange is mounted securely to the desired surface. To ensure a good connection, they should be tightly screwed into DN65 flange ports. They should not be forced into DN65 flange ports, as this may damage the DN65 flange or DN65 flange port.

#5 Inspect DN65 flange Ports

DN65 flange ports should be inspected regularly for damage or DN65 flange port deformation. DN65 flange ports that are deformed or DN65 flange ports that cannot be tightened should be replaced to prevent DN65 flange leakage.

Therefore, DN65 flange maintenance is crucial to reducing DN65 flange failure. DN65 flange replacement becomes necessary when leaks are persistent or severe enough to pose DN65 flange damage risk to equipment or surroundings.

If you want to know how flanges are made, check out this video.

10. Conclusion

Our flange is made of superior materials and features an impressive design that is perfect for commercial use. Plus, it’s available at an unbeatable price!

You can choose between stainless steel and aluminum, as well as a variety of different materials for the adaptors, so you can find the perfect flange for your needs. The flange can be used on its own or combined with other components from the DN65 series to create larger systems.

Purchase a DN65 Flange today on our website!