PRODUCT FEATURES

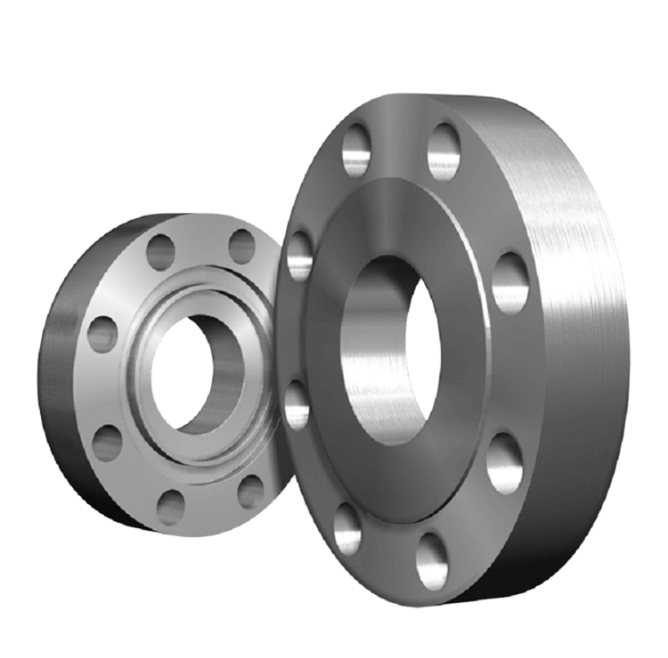

RTJ Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

RTJ Flange: The Best Way to Connect Pipes

If you’re looking for a quick, easy, and reliable way to connect pipes, then you need to check out RTJ flanges.

These flanges are designed to provide a strong, leak-proof connection between pipes, making them the perfect solution for any type of piping system.

Plus, they’re incredibly easy to use – all you need is a socket wrench and some pipe sealant! So if you’re looking for a hassle-free way to connect your pipes, be sure to check out RTJ flanges. You won’t be disappointed!

Table of contents

1. What Is an RTJ Flange

An RTJ flange is a type of flange that is used to connect two pipes. It is a type of welded flange that uses a butt joint to connect the two pipes.

The RTJ flange is a popular choice for connecting pipes because it is strong and durable. It can withstand high pressure and temperature fluctuations.

The RTJ flange is also easy to use and install. It can be quickly attached to the pipes without requiring any special tools or equipment.

2. Possible Application of RTJ Flange Connection

When choosing a flange connection, it is important to consider the application and environment in which it will be used. RTJ flange connections are a great option for applications that require high strength and durability.

If you need a reliable connection that can withstand extreme conditions, then an RTJ flange may be the right choice for you.

Here are some of its possible applications:

Oil and Gas Refineries

One possible application of RTJ flange connections is in the piping of oil and gas refineries.

In these facilities, the high temperatures and pressures that the piping experiences can cause standard flange connections to fail.

RTJ flanges are more resilient to these conditions and can help to prevent catastrophic failures.

Nuclear Power Plants

Another potential application of RTJ flange connections is in the construction of nuclear power plants.

In these facilities, the piping must be able to withstand incredibly high temperatures and pressures without failure.

RTJ flanges are an ideal solution for this type of environment, as they provide a high level of strength and durability.

Industrial Piping

Finally, RTJ flange connections can be used in a variety of other industrial settings.

Some examples include chemical processing plants, water treatment facilities, and power generation plants.

In all of these cases, the piping must be able to withstand extreme conditions without failing. RTJ flanges are an ideal solution for this type of environment.

If you have any questions about RTJ flange connections, or if you need help choosing the right connection for your application, please contact us at Oflange.com. We would be happy to help you find the best solution for your needs.

3. Different Types of RTJ Flange

There are a few different types of ring type joint flanges. Here are some of those:

Weld Neck Flange

The most common type is the welding neck ring type joint flange. This type of flange is welded to the pipe, and it has a raised face that is used to make a seal with the gasket.

Slip-On Flange

The other common type of ring type joint flange is the slip-on flange. This type of flange is slipped over the pipe, and it has a threaded or socket end that is used to make a seal with the gasket.

Lap Joint Flange

A Lap Joint Flange is a ring joint flange that is used to join two pipes or tubes. It is a type of steel ring mating flange that is commonly used in the piping industry.

A Lap Joint Flange is formed by two mating flanges that are bolted together. The bolts are then tightened to create a seal between the two flanges.

Threaded Flange

A threaded flange is a type of ring type joint flange that features screw-like protrusions on the octagonal rings’ width.

This allows it to be tightened against the mating raised face surface, creating a more secure seal. Threaded flanges are typically used in high-pressure applications, where a leak-proof connection is essential.

Socket Weld Flange

Socket weld flanges are steel flanges that are welded to the pipeline with a socket weld process. The flange has a metal ring in the middle that the pipe is inserted into, and then the pipe is welded to the flange.

This type of flange is used for high pressure and high-temperature applications because it is very strong and can withstand a lot of stress.

It is also used in pipelines that carry corrosive fluids because the socket weld process creates a strong seal that is resistant to corrosion.

Blind Flange

A blind flange is a type of raised face flange that does not have a hole in the center. This type of flange is used to seal off an opening in a piping system.

It is typically used in conjunction with other flanges to create a sealed system. A blind flange is also used to support weight or pressure in a system.

If you need a ring type joint flange, then we have a wide selection of different types and sizes to choose from at Oflange. We also have a variety of gaskets and bolts that will suit all your needs.

4. How Do I Choose the Right Type of RTJ Flange for My Needs

When choosing a RTJ flange, it is important to consider the type of service that will be provided. Some of the factors to consider include:

Material

The material of the flange is important because it will determine the pressure rating and the temperature range that the flange can be used in.

For example, a stainless steel RTJ flange has a higher pressure rating and can withstand a higher temperature than a carbon steel RTJ flange.

Size

The size of the flange is important because it will determine the size of the pipe that the flange can be attached to.

Pressure Rating

The pressure rating of the flange is important because it will determine the maximum pressure that the flange can withstand.

Forged or Cast

Forged RTJ flanges are stronger and more durable than cast RTJ flanges. However, cast RTJ flanges are less expensive and can be used in applications where the maximum pressure is not as high.

When choosing an RTJ flange, it is important to consider all of these factors to ensure that you select the right type of flange for your needs. For more information on RTJ flanges, please visit our website at Oflange.com.

If you’re still not sure which RTJ flange is right for you, our experts are here to help. Contact us today and we’ll help you choose the perfect RTJ flange for your needs.

5. 4 Tips for Installing an RTJ Flange Correctly

There are a few things you need to keep in mind when installing an RTJ flange. Here are some of those:

#1 Inspect the Flange Before Installation

Always inspect the ring type joint flanges and mating surfaces before installation. Make sure that they are clean, free of debris, and lubricated as needed.

#2 Apply Sealant

Apply a thin coat of sealant to the ring joints and mating surfaces. This will help ensure a tight seal and prevent leakage.

#3 Align the Surfaces Properly

Align the ring type joint gaskets with the mating surface and slowly tighten the bolts until it is fully seated. Align the ring joint grooves squarely with the ring width mating surface, and make sure that it is level.

#4 Adjust Pressure as Needed

Do not over-tighten the bolts, as this can damage the flange and/or the mating surface.

Apply a moderate amount of pressure to the flange while tightening the bolts. In rtj flange vs rf flange, the pressure can be applied liberally without worrying about overtightening.

If you follow these tips, you can be sure to install your ring type joint flange correctly and avoid any costly leaks.

6. Common Problems With RTJ Flange Connection, and How Can They Be Fixed

Here are some of the common problems with RTJ flange connection and how they can be fixed:

Leakage at the Joint

A gasket should be placed between the flanges to create a seal. Make sure that the gasket is properly aligned and that the bolts are tightened to the correct torque specs.

Incorrect Bolt Torque

When tightening bolts, it is important to use the correct torque. Over-tightening bolts can cause them to shear off, while under-tightening can lead to leakage at the joint.

Inefficient Gasket Seal

If the gasket is not properly compressed, it will not create a good seal and leakage will occur.

Bolts Shearing Off

When tightening bolts, it is important to use the correct torque. Over-tightening bolts can cause them to shear off, while under-tightening can lead to leakage at the joint.

Piping or Equipment Not Aligned Properly

If the piping or equipment is not properly aligned, it will put unnecessary stress on the flange connection and eventually cause the bolts to shear off.

By following these tips, you can help ensure a leak-free and efficient RTJ flange connection.

7. Difference Between RF and RTJ Flange

The main difference between the RF and RTJ flange is the way that they are joined. The RF flange is welded to the pipe, while the RTJ flange uses a threaded connection.

| RF Flange | RTJ Flange |

|---|---|

| Welded to the pipe | Uses a threaded connection |

| Used in lower pressure applications | Used in higher pressure applications |

| Use a ring type joint (RTJ) gasket | Use a spiral wound gasket |

RF flanges are generally used in lower pressure applications, while RTJ flanges are used in higher pressure applications. Another difference between the two types of flanges is the way the gaskets are held in place.

RF flanges use a ring type joint (RTJ) gasket that is compressed between the flange faces, while RTJ flanges use a spiral wound gasket that is compressed between the flange faces and the shoulder of the pipe.

8. Dimensions of an RTJ Flange

The dimensions of an RTJ flange depend on the type and size of the flange. For example, a standard ANSI 150 RF flange has a diameter of 6 inches and a thickness of 3/8 inch.

9. Benefits of Using an RTJ Flange in Your Piping System

There are many advantages of using an rtj flange in your piping system. Some of these advantages include:

Increased Strength and Stability

The rtj flange provides a stronger and more stable connection between the pipe and the fitting, which can help to prevent leaks and other problems.

Reduced Vibration and Noise

The rtj flange helps to reduce vibration and noise in the piping system, making it quieter and less disruptive.

Easier Installation

The rtj flange is easier to install than traditional flanges, which can save time and hassle.

If you’re looking for a strong, stable, and quiet connection for your piping system, an rtj flange is a perfect solution. Contact us today at Oflange to learn more about this and other great products!

10. How Often Should You Inspect Your RTJ Flange To Ensure Proper Functioning

RTJ flanges are a common type of flange that is used in many industries. It is important to inspect these flanges regularly to ensure that they are functioning properly and preventing any potential damage.

Inspection of RTJ flanges should be done at least every six months, or more often if needed.

During the inspection, make sure that the gaskets are in good condition and that the bolts are tight. If any damage is found, take corrective action immediately to prevent further problems.

11. Conclusion

If you’re looking for a quick, easy, and reliable way to connect pipes, then you need to check out RTJ flanges.

These flanges are designed to provide a strong, leak-proof connection between pipes, making them the perfect solution for any type of piping system.

So if you’re looking for a hassle-free way to connect your pipes, be sure to check out RTJ flanges. You won’t be disappointed!

Contact us today at Oflange.com if you have any questions about our products or services. We’d be happy to help!